High-efficiency preparation method for glossy ganoderma polysaccharide

A high-efficiency technology of Ganoderma lucidum polysaccharide is applied in the field of high-efficiency preparation of Ganoderma lucidum crude polysaccharide, which can solve the problems of low polysaccharide purity, low extraction yield, long production cycle, etc., and achieve the effects of improving extraction yield, simple equipment and small energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] (1) Experimental design

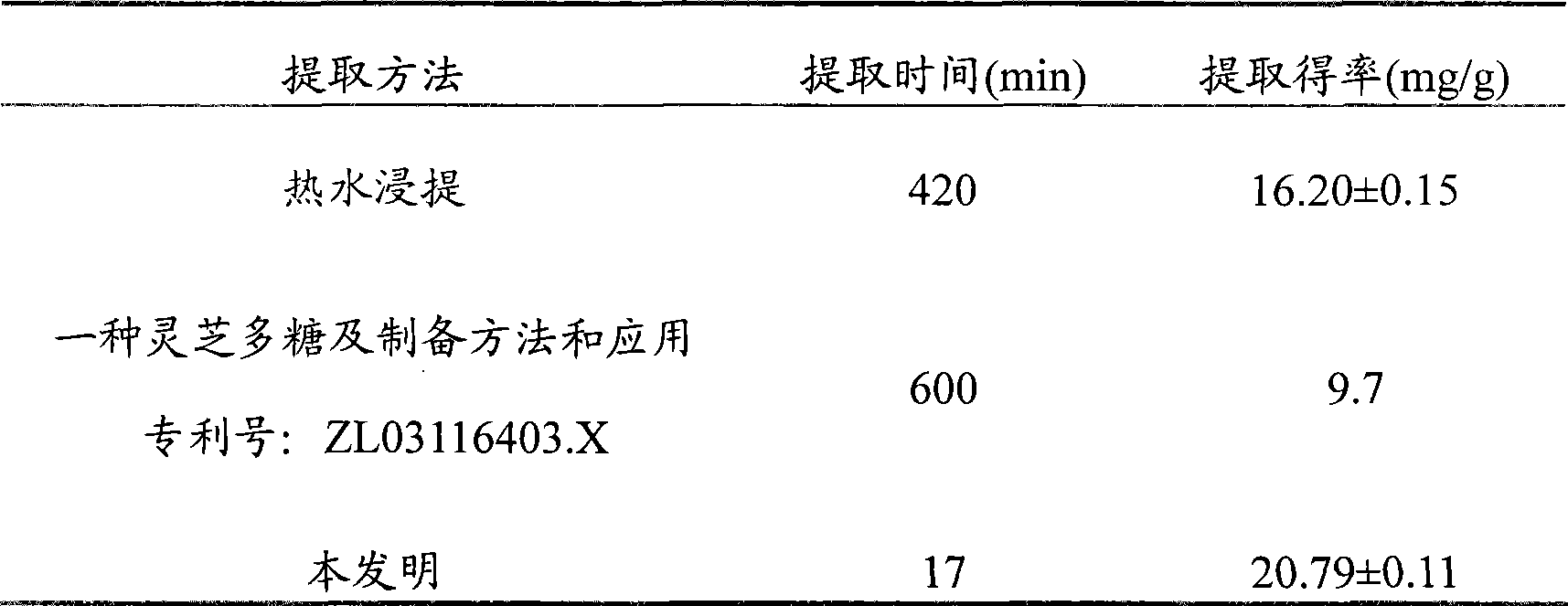

[0019] 1. Hot water extraction method (comparison)

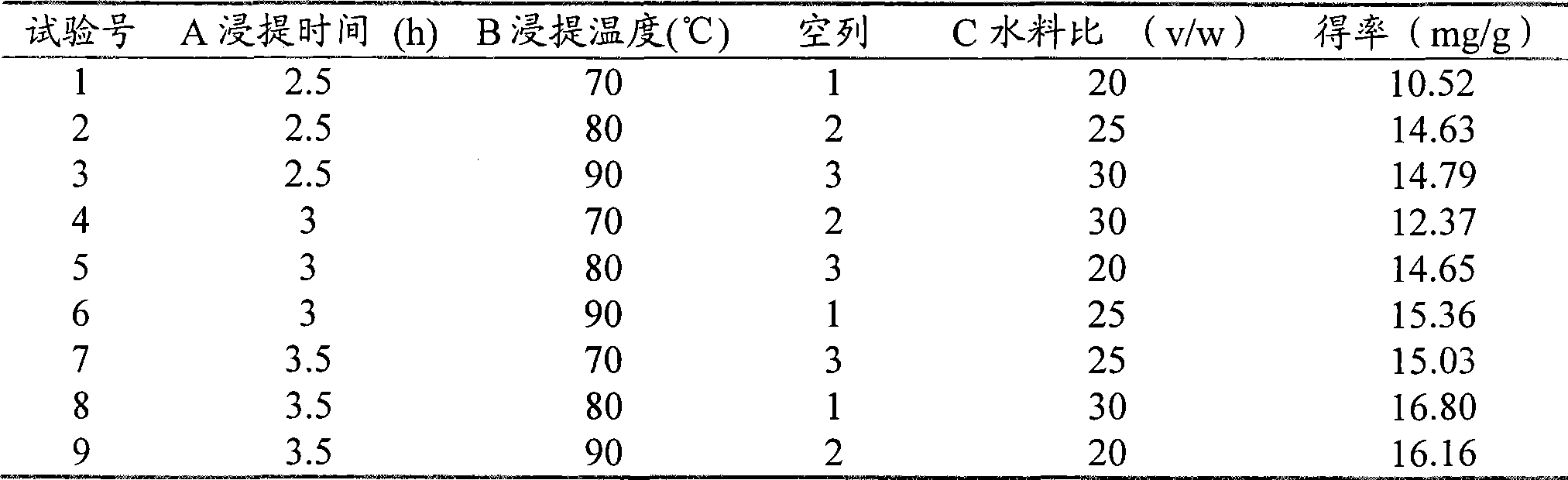

[0020] Select water-material ratio, leaching times, leaching temperature and leaching time to do single factor test; orthogonal experiment choose leaching temperature, water-material ratio and leaching time as examination factors, take polysaccharide yield as measuring index, L 9 (3 4 ) Orthogonal test method (Table 1) to determine the optimal process parameters of Ganoderma lucidum polysaccharide hot water extraction.

[0021] 2. Ultrasonic extraction method (scheme of the present invention)

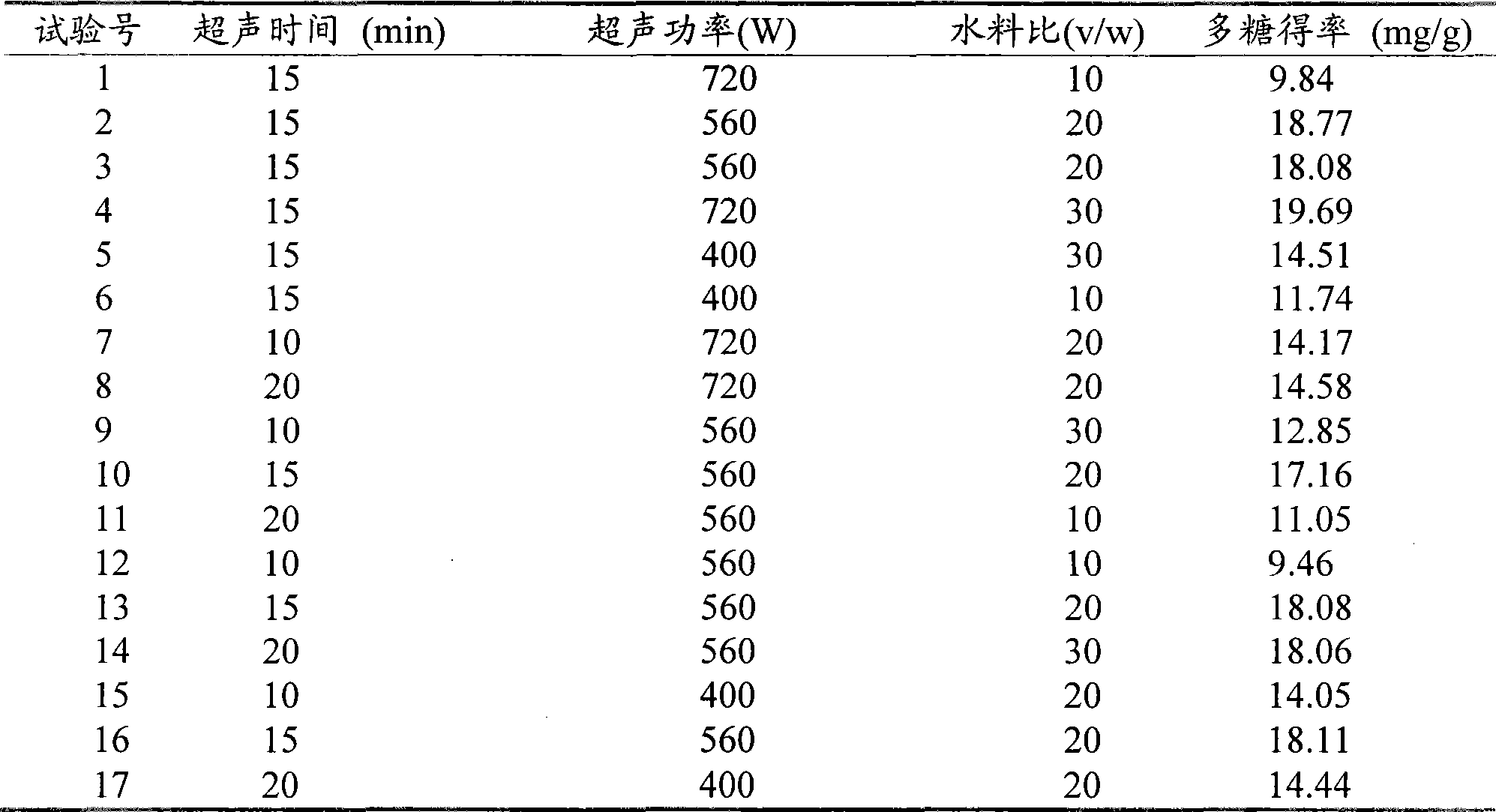

[0022] Ultrasonic power, ultrasonic action time, and water-material ratio were selected as single factor experiments; Box-Benhnken design selected ultrasonic power, ultrasonic action time, and water-material ratio as the examination factors, and polysaccharide yield was used as the measurement index, and the response surface design method was adopted (Table 1). 2), to determine the optimal process p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com