Method for dismutation electrolytic production of hydrogen, copper, lead, zinc, acid and alkali-chloride by elemental sulfur

An elemental sulfur, elemental technology, applied in the field of hydrometallurgy, can solve problems such as the need for time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

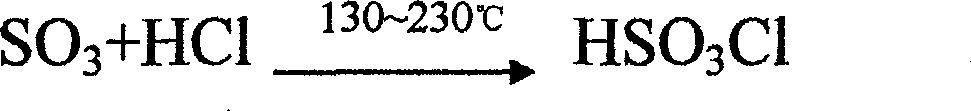

Method used

Image

Examples

Embodiment Construction

[0037] The condition of elemental sulfur normal temperature phase transfer catalyzed disproportionation is that the molar ratio is 1 sodium citrate and ammonium citrate saturated aqueous solution, with the supersaturated kerosene organic phase of dissolving sulfur, with quaternary ammonium salt trioctyl methyl ammonium hydroxide ( OCl 3 MeN + h - ) is a phase transfer catalyst. Under the condition of full stirring at normal temperature and pressure of 50-90°C, elemental sulfur disproportionates to form sulfide or polysulfide and thiosulfate into the water phase. The mass ratio of phase transfer catalyst to sulfur and kerosene Choose 1: 3~5: 15~30, and control the pH range of the end point from 3 to 5. The disproportionation reaction can be expressed as:

[0038] 6OH - +4S→2S 2- +S 2 o 3 2- +3H 2 o

[0039] Disproportionation reactions that also occur include:

[0040] 4S+3H 2 O→S 2 o 3 2- +2H 2 S+2H +

[0041] 3S+60H - → SO 3 2- +2S - +3H 2 o

[0042] 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com