Carbon nitride polyporous material and use thereof for hydrogen storage

A porous material, carbon and nitrogen technology, applied in the field of inorganic nanomaterials chemistry and new energy, can solve the problems of not being able to change the composition of carbon skeleton elements, reduce the pore volume and specific surface area of carbon materials, achieve easy control, improve hydrogen storage performance, The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 4.4g of ethylenediamine, 10.8g of carbon tetrachloride, and 1.0g of SBA-15 template were mixed, and after two hours of magnetic stirring, the temperature of the mixture was raised to 90°C, and stirred and refluxed for 6h. The obtained samples were first dried at 100°C for one night, and then put into a tube into a furnace. Under a nitrogen atmosphere, the temperature was raised to 600°C at a heating rate of 5K / min, kept for 6 hours, and then cooled to take out the samples. 8% HF acid removed the silicon template, followed by multiple washes with ethanol and water. Finally, it is dried in air at 100°C, and the obtained product is ordered mesoporous carbonitride, abbreviated as MCN-1. A certain amount of MCN-1 samples were placed in a tube furnace, and argon was used as a protective atmosphere, and the temperature was raised to 950 °C at a heating rate of 5 °C / min. Turn off the argon gas source, introduce a carbon dioxide atmosphere with a flow rate of 22mL / min, keep it ...

Embodiment 2

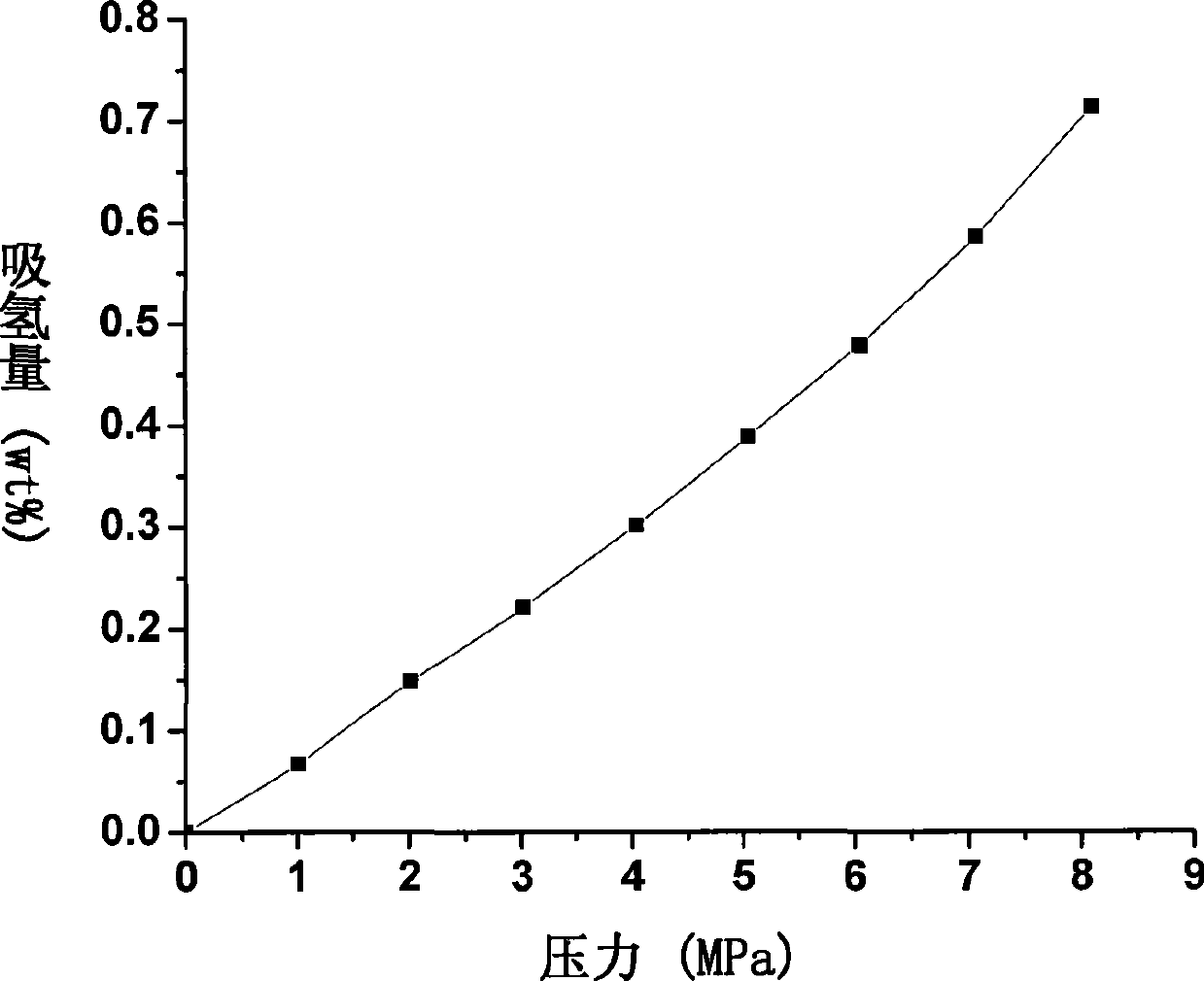

[0030] This example is basically the same as Example 1, except that in the subsequent carbon dioxide activation process, the activation time is 3 hours. The obtained sample is abbreviated as MCN-1-3h. At room temperature, the sample was first vacuumed for 12 hours to activate the sample, and then high-purity hydrogen was introduced to pressurize, in which every ten atmospheres of pressure was balanced and stable for 2 hours, and the pressure was increased to 80 atmospheres.

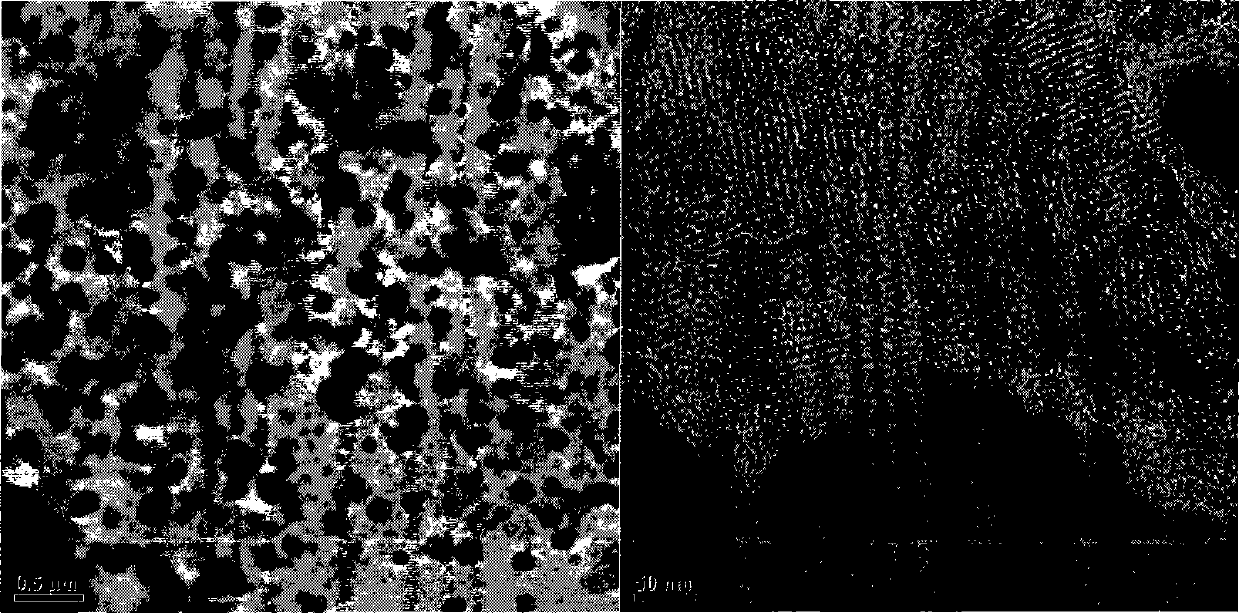

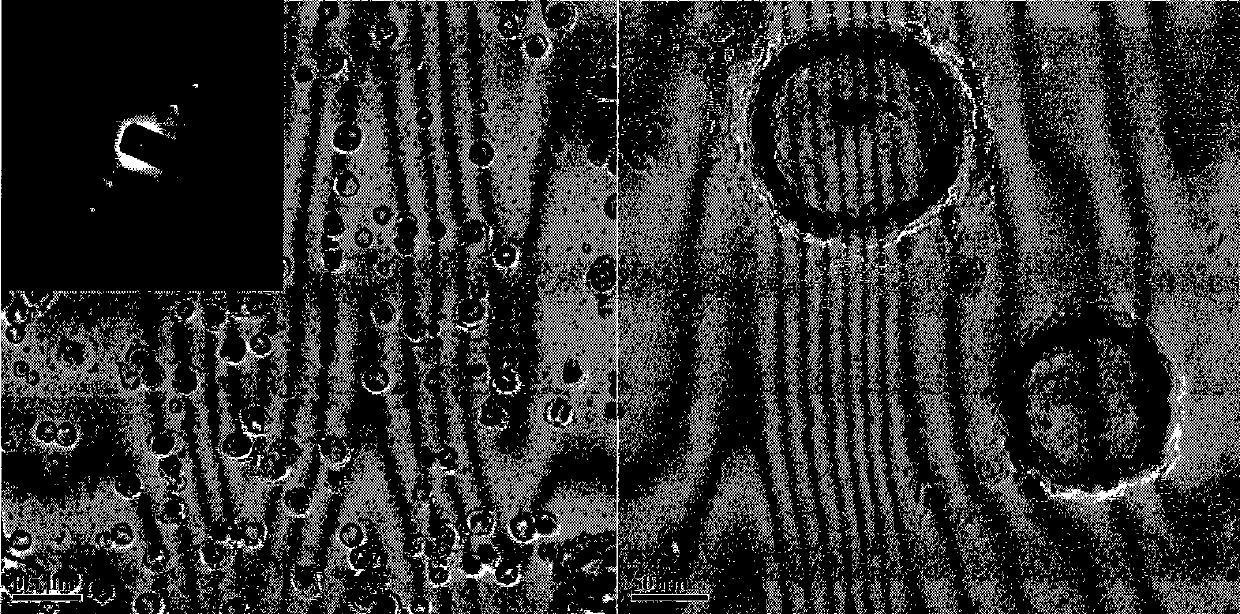

[0031] image 3 Shown is the transmission electron microscope image of the prepared MCN-1-3h sample. It can be seen that the particles still maintain a spherical shape, are well dispersed, and the interior of the particles is a vacuum structure. The particle outer diameter is about 250nm, and the shell thickness is about 20nm. The mesoporous structure of the shell wall has completely disappeared, and a rich disordered microporous structure is formed, and the micropore size is about 0.7nm. Such micropo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com