Anode material capable of reducing capacity attenuation after storing lithium manganate battery

A lithium manganate battery and capacity decay technology, which is applied in the field of electrochemistry, can solve the problems of improving the capacity recovery rate after lithium manganate storage, the increase of electrode polarization and other problems that have not been clearly proposed, so as to improve the capacity recovery rate and reduce the capacity Attenuation, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

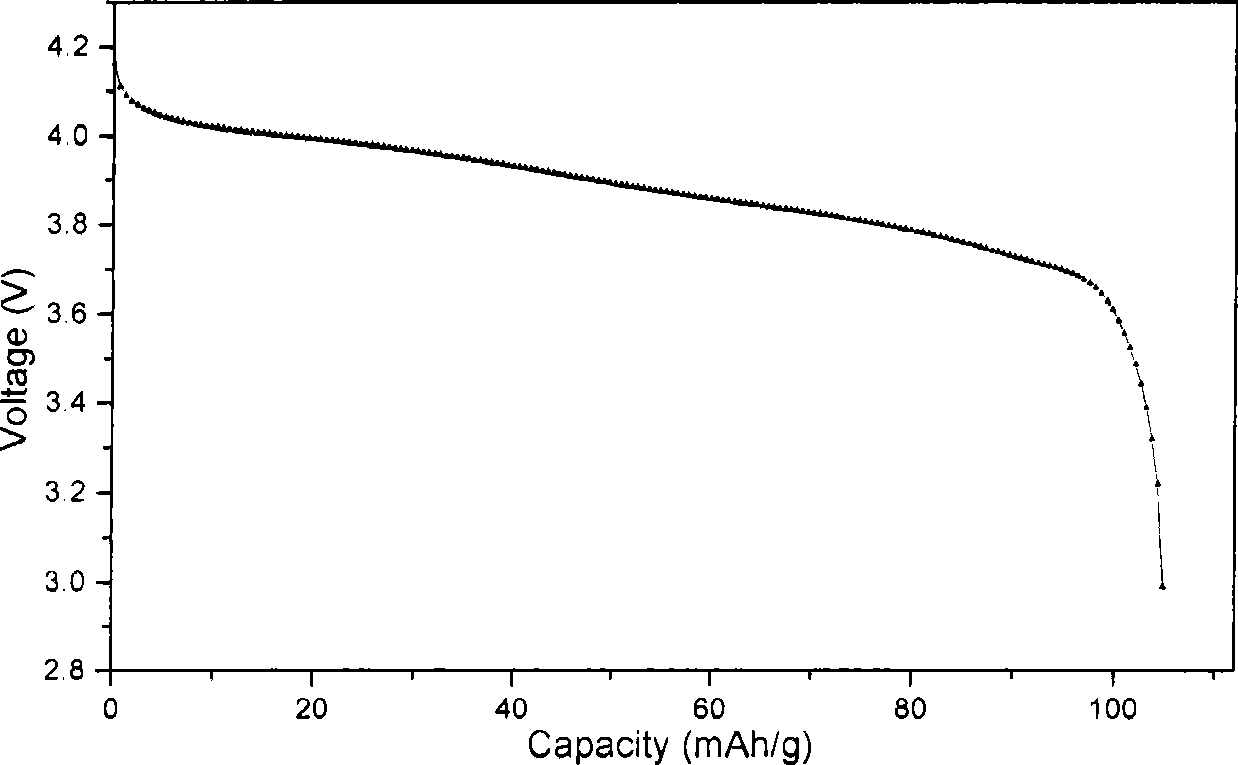

[0031] Take 94 grams of lithium manganate, 2 grams of Li 2 CO 3 , 2 grams of LiOH and 2 grams of nano-carbon fiber, mixed at high speed to form 100 grams of lithium manganate battery positive electrode material, and then, according to the conventional lithium-ion battery positive electrode production process, mixed with binders, conductive agents, additives, solvents, etc. Slurry is made into a positive electrode sheet of a lithium-ion battery through coating, drying, film rolling, and slitting. Its gram capacity is 110.2mAh / g. According to the conventional lithium-ion power battery manufacturing process, a lithium manganese oxide power battery is produced, and its gram capacity after 28 days of storage is 108.1mAh / g.

Embodiment 2

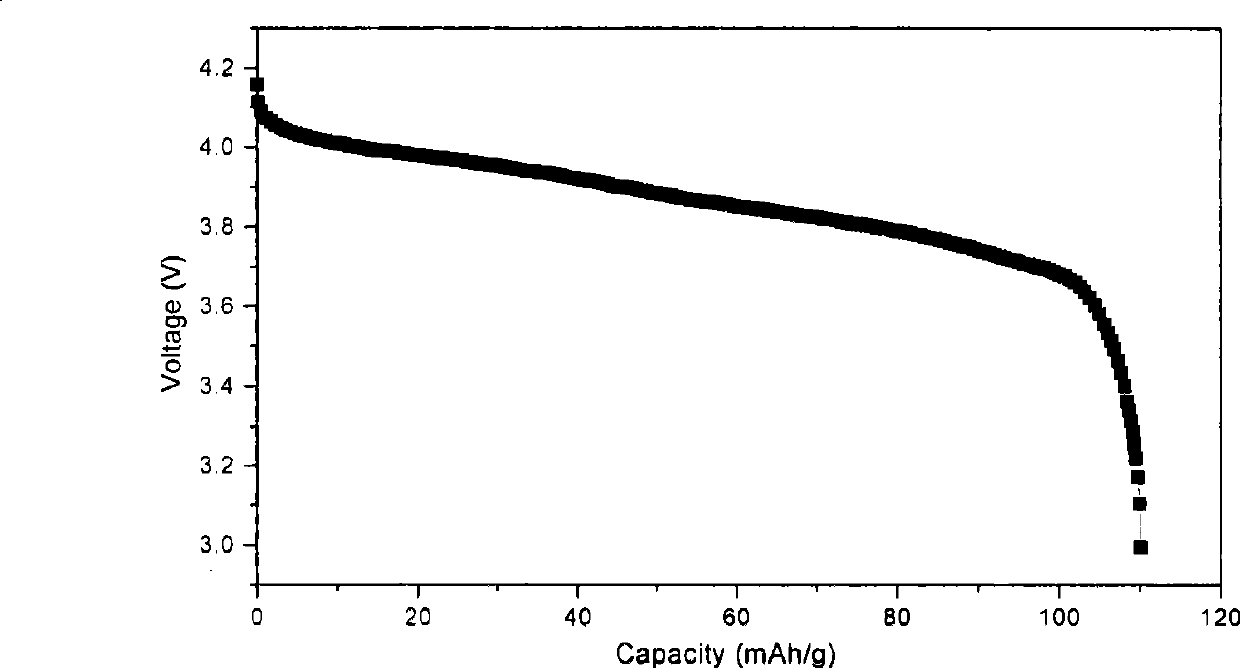

[0033] Take 96 grams of lithium manganate, 1.5 grams of Li 2 CO 3 , 1 gram of LiF and 1.5 grams of nano-carbon fiber, mixed at high speed to form 100 grams of lithium manganate battery positive electrode material, and then, according to the conventional lithium-ion battery positive electrode production process, mixed with binders, conductive agents, additives, solvents, etc. Slurry is made into a positive electrode sheet of a lithium-ion battery through coating, drying, film rolling, and slitting. Its gram capacity is 109.8mAh / g. According to the conventional lithium-ion power battery manufacturing process, a lithium manganese oxide power battery is produced, and its gram capacity after 28 days of storage is 107.9mAh / g.

Embodiment 3

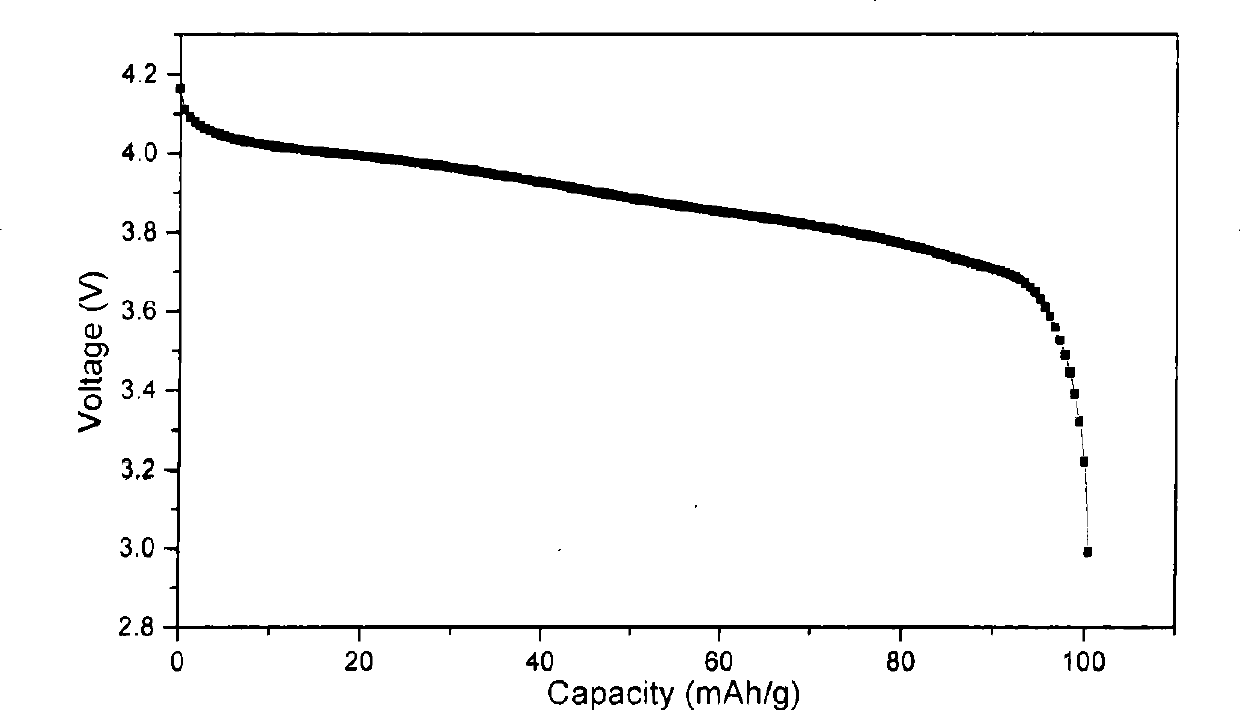

[0035] Take 97 grams of lithium manganate, 1 gram of Li 2 CO 3 , 1 gram of LiF and 1 gram of carbon nanofiber, mixed at high speed to form 100 grams of lithium manganate battery positive electrode material, and then, according to the conventional lithium ion battery positive electrode production process, mixed with binders, conductive agents, additives, solvents, etc. Slurry is made into a positive electrode sheet of a lithium-ion battery through coating, drying, film rolling, and slitting. Its gram capacity is 110.6mAh / g. According to the conventional lithium-ion power battery production process, a lithium manganate power battery is produced, and its gram capacity after 28 days of storage is 108.4mAh / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com