Artificially intensified preanhydration method for sludge

A kind of sludge and artificial technology, applied in the direction of dehydration/drying/concentrated sludge treatment, energy wastewater treatment, etc., can solve the problems of long cycle, generation of a large amount of malodorous gas, and influence on the surrounding environment, so as to improve the air permeability and increase the air permeability and evaporation area, the effect of reducing mechanical energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

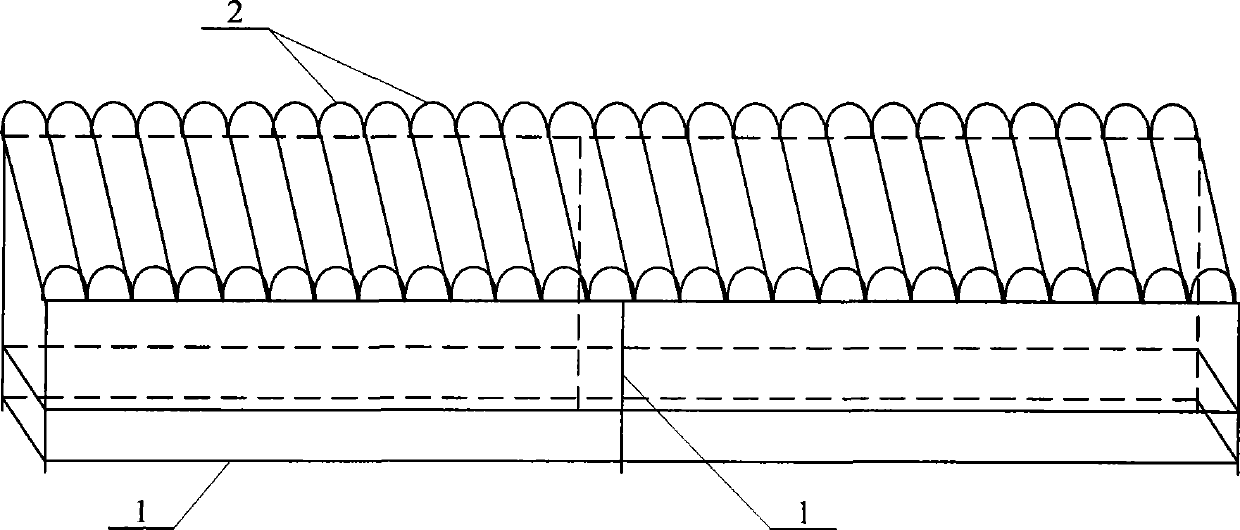

[0009] Specific implementation mode one: (see figure 1 ) The technical scheme of this embodiment is realized by the following steps: one, on the hard cement ground or on the ground where the waterproof layer is laid, build a sun-drying shed with a waveform light-transmitting and rain-proof ceiling 2 on the top; two, after the dehydration of the sewage treatment plant The sludge (with a moisture content of about 80%) is mixed with a conditioner, the volume ratio of the sludge to the conditioner is 1:0.3~2, and the conditioner is one or more of pumice, vermiculite, perlite, zeolite or sand It is made of multiple compounds, and the particle size of the conditioning agent is (average diameter) 0.4-80mm. 3. Dry the mixed material obtained in step 2 on the hard cement floor or the ground where the waterproof layer is laid in step 1, and dry it on the ground Filling or gravel layers can also be set, and the drying site should be selected in a well-ventilated and sunny location. Vert...

specific Embodiment approach 2

[0010] Specific embodiment 2: In this embodiment, the mixing of sludge and conditioner is 1:1 by volume. Others are the same as in the first embodiment.

specific Embodiment approach 3

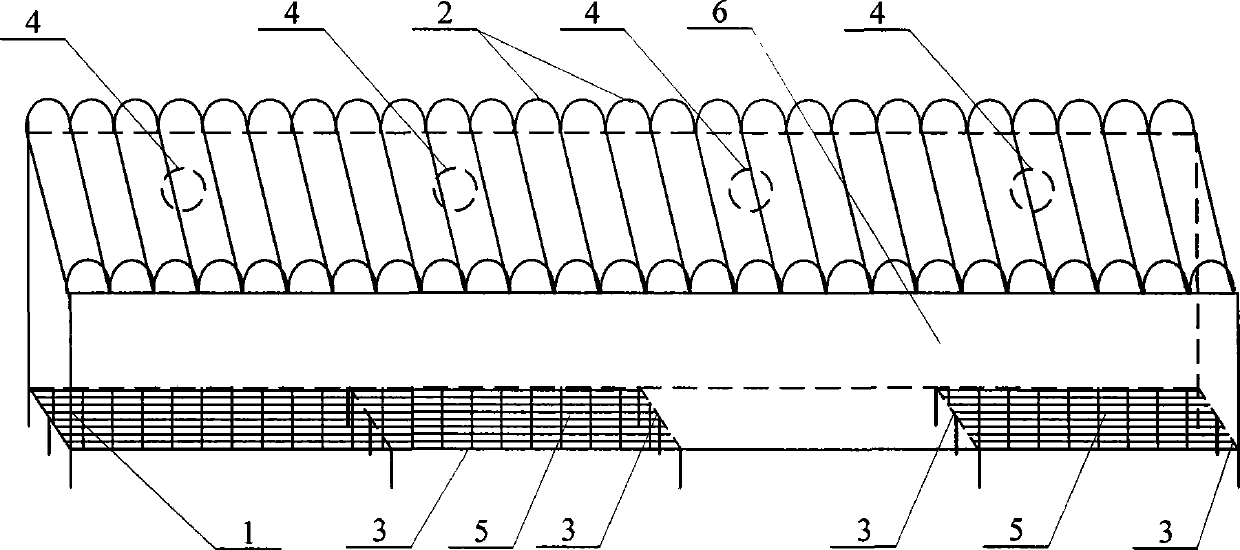

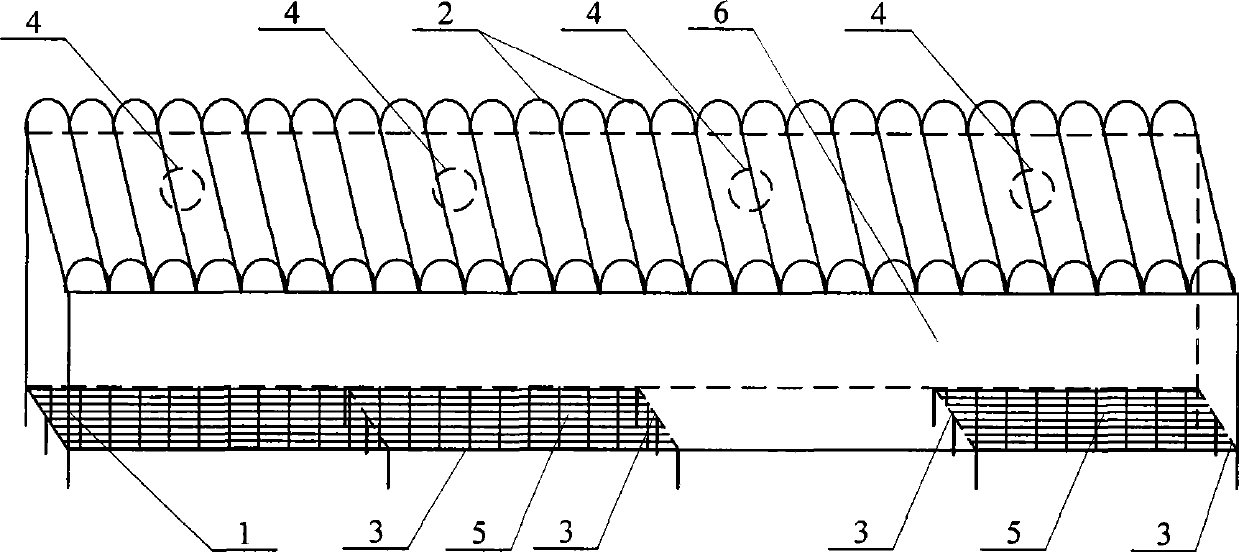

[0011] Specific implementation mode three: (see figure 2 ) The technical scheme of the present embodiment is realized by the following steps: one, build the top to be provided with the sun-drying awning of corrugated light-transmitting rain-proof ceiling 2, the bottom of the airing shed is the suspended bed bottom plate 5, and air can flow at the bottom of the bed, has increased air and The contact area of the drying material, two, preparation conditioner, conditioner is one or more of pumice, vermiculite, perlite, zeolite or sand composition compounded in any proportion, the particle size of conditioner is (average diameter) 0.4 ~80mm, 3. After the sludge and conditioner are fully mixed at a volume ratio of 1:0.5~2, they are stacked on the suspended bed bottom 5 composed of perforated plates or stainless steel mesh, and the material stacking height is 0.3~0.7m. The hole diameter of the bottom plate should be able to stop the mixture of conditioner and sludge from falling. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com