Preparation of high molecular weight polyester

A high-molecular-weight polyester technology, applied in the field of polymer material preparation, can solve the problems of difficult continuous production, easy agglomeration, affecting polymer properties, etc., achieve uniform product properties, prevent agglomeration, and improve heat transfer performance. average effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

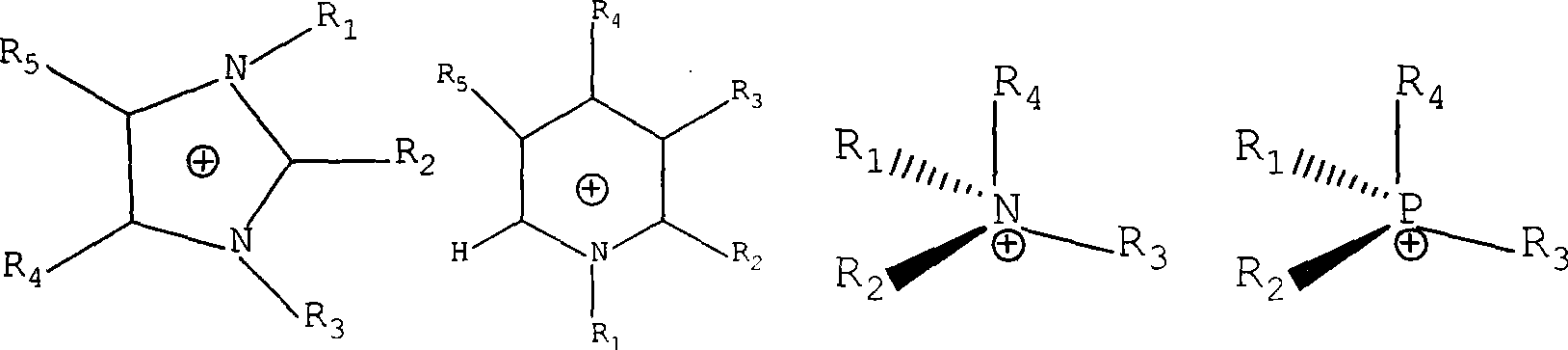

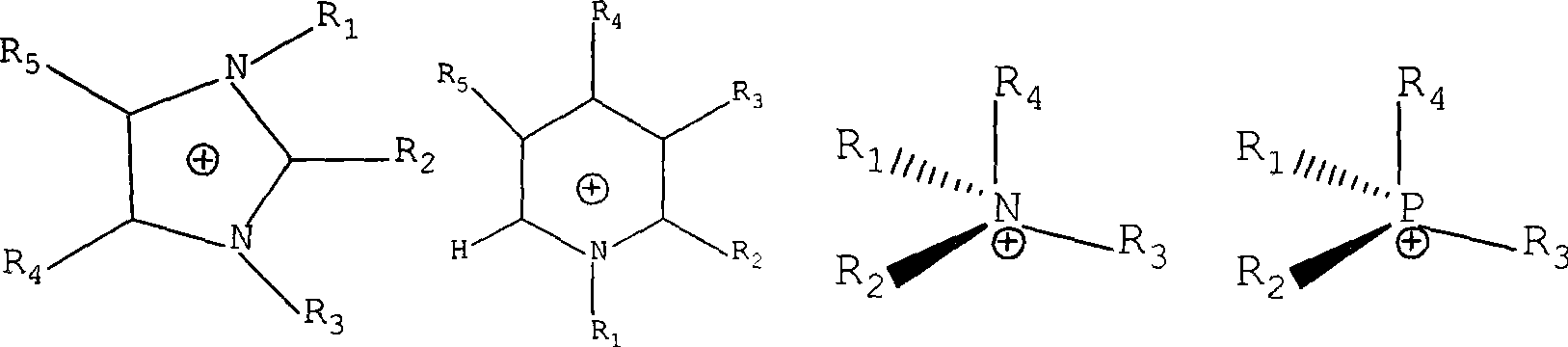

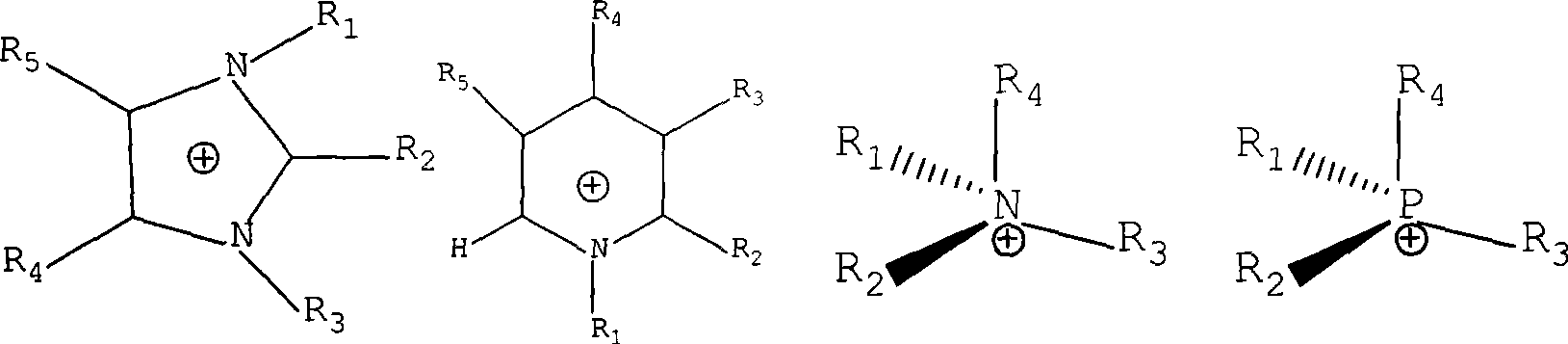

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: N-butylpyridine hexafluorophosphate

[0058] Starting material: lactic acid prepolymer, molecular weight Mw=10k, melting enthalpy ΔHm=60J / g, melting point Tm=158°C, glass transition temperature Tg=45°C

[0059] Ionic liquid: 1-ethyl-3-methylimidazolium tetrafluoroborate

[0060] Inject 250ml of ionic liquid 1-ethyl-3-methylimidazolium tetrafluoroborate into a 500ml four-neck flask equipped with mechanical stirring (anchor type stirring blade). One port of the four-neck flask was connected to nitrogen gas, the other port was connected to a vacuum system, and the other port was inserted into a thermocouple thermometer. After the four-necked flask was placed in an oil bath, the vacuum was turned on, and nitrogen was replaced three times. Under a nitrogen atmosphere, 10 g of lactic acid prepolymer was slowly added into a four-necked flask. After turning on the vacuum and reducing the pressure to 200Pa, raise the temperature to 170°C, and stir at a stirring ...

Embodiment 2

[0062] Starting material: lactic acid prepolymer, molecular weight Mw=10k, melting enthalpy ΔHm=60J / g, melting point Tm=158°C; glass transition temperature Tg=45°C

[0063] Ionic liquid: 1-butyl-3-methylimidazolium tetrafluoroborate

[0064] Inject 250ml of ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate into a 500ml four-neck flask equipped with mechanical stirring (anchor type stirring blade). One port of the four-neck flask was connected to nitrogen gas, the other port was connected to a vacuum system, and the other port was inserted into a thermocouple thermometer. After the four-necked flask was placed in an oil bath, the vacuum was turned on, and nitrogen was replaced three times. Under a nitrogen atmosphere, 10 g of lactic acid prepolymer was slowly added into a four-necked flask. After turning on the vacuum and reducing the pressure to 200Pa, raise the temperature to 170°C, and stir at a stirring speed of 1000rpm for 10-30 minutes after the prepolymer is m...

Embodiment 3

[0066] Starting material: lactic acid prepolymer, molecular weight Mw=20k, melting enthalpy ΔHm=58J / g, melting point Tm=160°C; glass transition temperature Tg=47°C

[0067] Ionic liquid: 1-butyl-3-methylimidazolium hexafluorophosphate

[0068] Inject 250ml of ionic liquid 1-butyl-3-methylimidazolium hexafluorophosphate into a 500ml four-neck flask equipped with mechanical stirring (anchor type stirring blade). One port of the four-neck flask was connected to nitrogen gas, the other port was connected to a vacuum system, and the other port was inserted into a thermocouple thermometer. After the four-necked flask was placed in an oil bath, the vacuum was turned on, and nitrogen was replaced three times. Under a nitrogen atmosphere, 10 g of lactic acid prepolymer was slowly added into a four-necked flask. After turning on the vacuum and reducing the pressure to 200Pa, raise the temperature to 170°C, and stir at a stirring speed of 500rpm for 10-30 minutes after the prepolymer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com