Rare earth silicates polycrystal material doped with Ce<3+> and preparing method thereof

A rare earth silicate, ion doping technology, applied in the growth of polycrystalline materials, chemical instruments and methods, single crystal growth and other directions, can solve the problems of the decline of crystal scintillation performance, deterioration of energy resolution, and reduction of crystal light output, etc. Achieve the effect of overcoming large individual differences, conducive to stability, and improving flicker performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

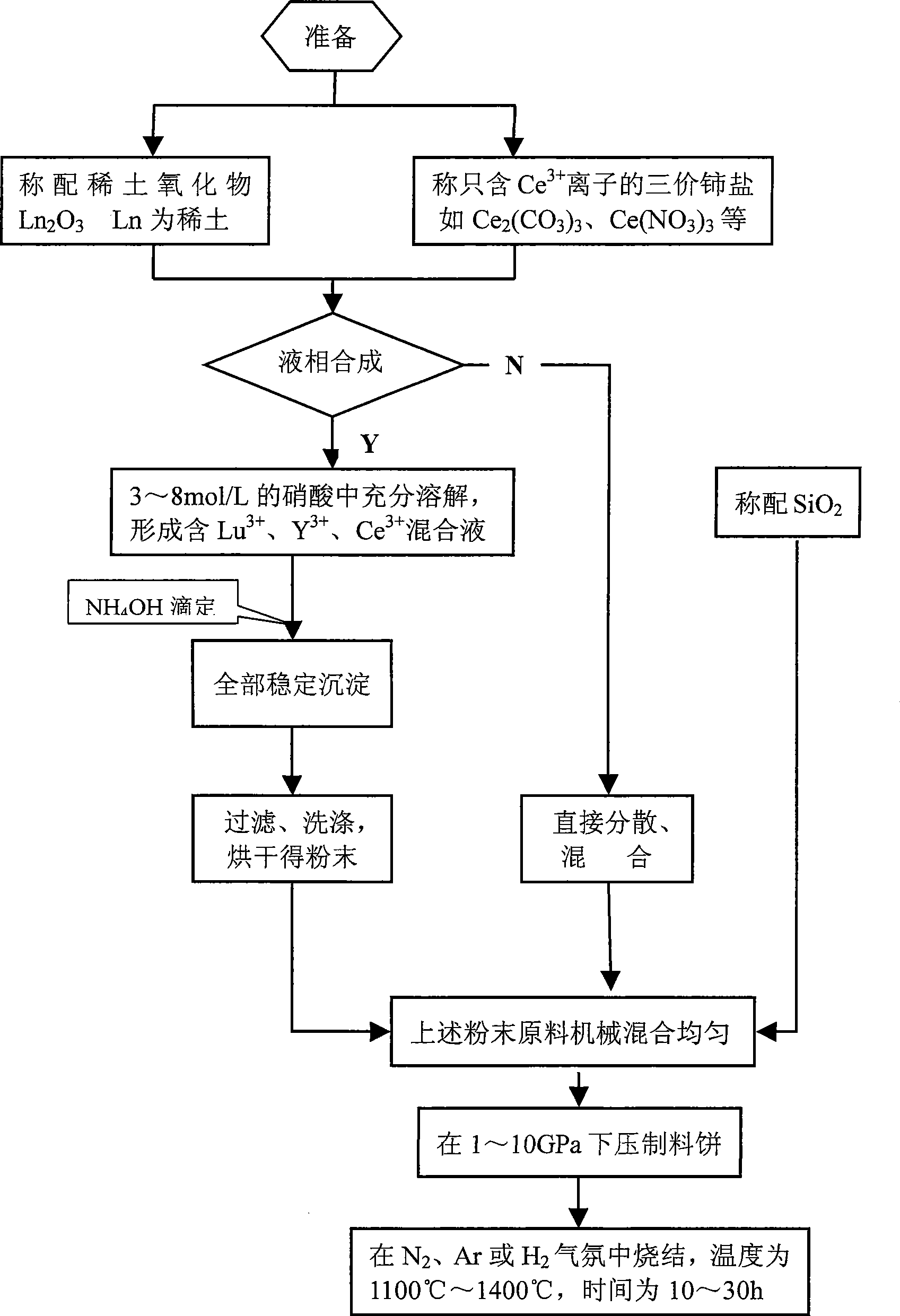

Method used

Image

Examples

Embodiment 1

[0043] Example 1. With Ce 2 (CO 3 ) 3 Direct synthesis of polycrystalline materials for dopants

[0044] to Ce 2 (CO 3 ) 3 As a dopant raw material, with the main raw material Lu 2 o 3 , SiO 2 Preparation of trivalent cerium ion Ce by direct mixing 3+ Lutetium silicate doped at 0.2 mol%: Lu 1.996 Ce 0..004 SiO 5

[0045] According to step (1) batching in described method A, weigh corresponding raw material components respectively, i.e. Lu 2 o 3 : Ce 2 (CO 3 ) 3 : SiO 2 =0.998:0.002:1 molar ratio, the total weight is about 1Kg; Ce 2 (CO 3 ) 3 As a dopant, with the main raw material Lu 2 o 3 , SiO 2 After direct ball milling to disperse and mix; press into a cake under a pressure of 5GPa in a press; 2 Sintered at 1400°C for 30h in a neutral atmosphere to obtain the required trivalent cerium ion-doped lutetium silicate (Lu 1.996 Ce 0..004 SiO 5 ) polycrystalline material.

Embodiment 2

[0046] Example 2. With Ce 2 (C 2 o 4 ) 3 Direct synthesis of polycrystalline materials for dopants

[0047] to Ce 2 (C 2 o 4 ) 3 As a dopant raw material, with the main raw material Lu 2 o 3 , SiO 2 Direct mixing to prepare Ce 3+ Lutetium silicate with an ion doping concentration of 0.2 mol%: Lu 1.996 Ce 0..004 SiO 5

[0048] According to step 1 batching described in method A, weigh corresponding raw material components respectively, i.e. Lu 2 o 3 : Ce 2 (C 2 o 4 ) 3 : SiO 2 =0.998:0.002:1 molar ratio, the total weight is about 1Kg; process step will Ce 2 (C 2 o 4 ) 3 , with the main raw material Lu 2 o 3 , SiO 2 After direct ball milling to disperse and mix; according to step press the press machine under the pressure of 5GPa to form a cake; adopt the process step to sinter at 1400°C for 30h in an inert atmosphere filled with Ar to obtain the desired Ce 3+ Ion-doped lutetium silicate (Lu 1.996 Ce 0..004 SiO 5 ) polycrystalline material.

Embodiment 3

[0049] Embodiment 3. With Ce (NO 3 ) 3 Direct synthesis of polycrystalline materials for dopants

[0050] With Ce(NO 3 ) 3 As a dopant raw material, with the main raw material Y 2 o 3 , SiO 2 Direct mixing to prepare Ce 3+ Yttrium silicate with an ion doping concentration of 0.2 mol%: Y 1.996 Ce 0..004 SiO 5

[0051] According to the ingredients in step 1 in method A, weigh the corresponding raw material components, namely Y 2 o 3 : Ce(NO 3 ) 3 : SiO 2=0.998:0.004:1 molar ratio, the total weight is about 1Kg; according to the process step in method A, Ce(NO 3 ) 3 As a dopant, with the main raw material Y 2 o 3 , SiO 2 After direct ball milling to disperse and mix; according to step 3, press the material cake under the pressure of 5GPa in the press machine; 2 The desired Ce 3+ Ion-doped yttrium silicate (Y 1.996 Ce 0..004 SiO 5 ) polycrystalline material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com