I-shaped electric-controlled beam scanning antenna housing constructed by microwave diode

A beam scanning and I-shape technology, applied in the field of radome, can solve the problems of complicated production process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

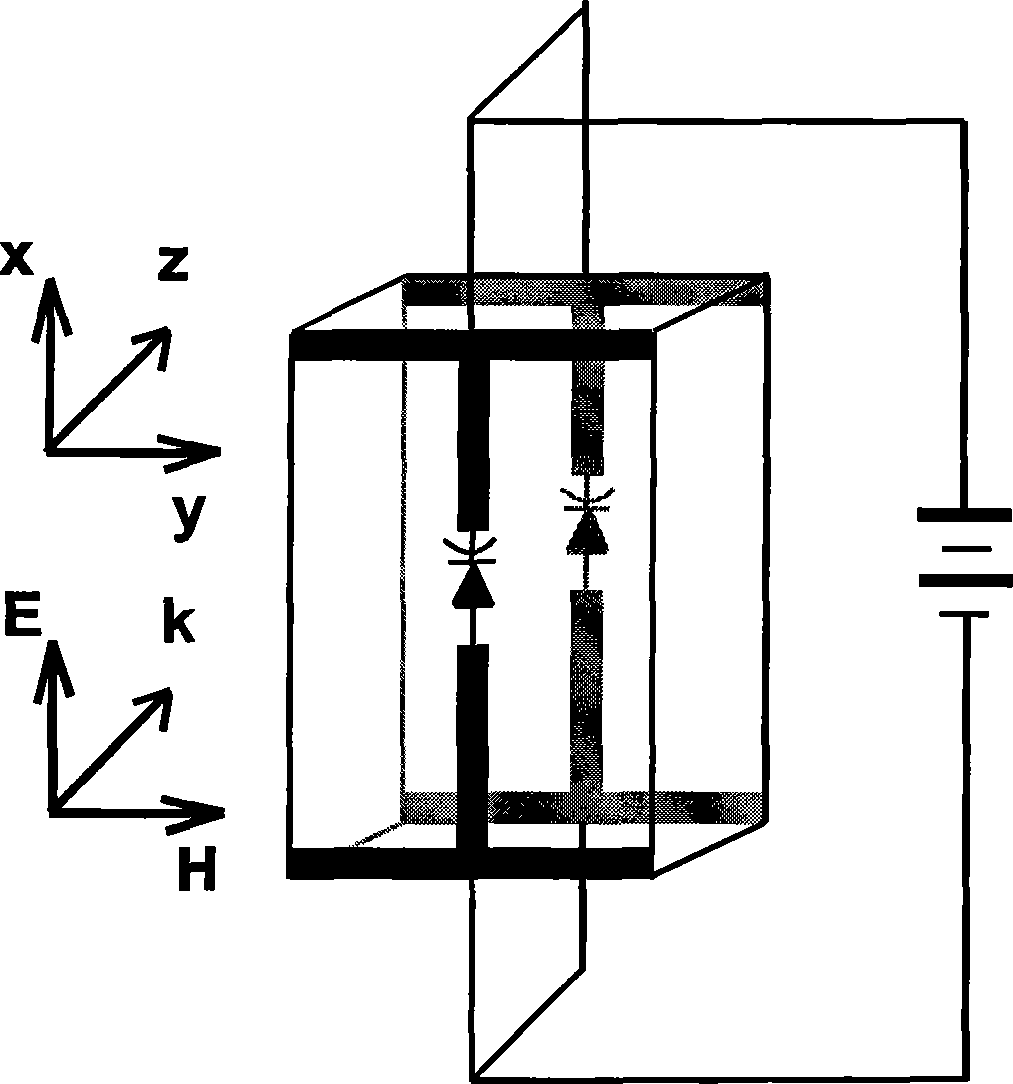

[0017] Such as figure 1 As shown, in order to manufacture this kind of radome that is convenient for voltage to control the scanning direction, a new material of double-sided I-shaped electrically controlled anisotropic medium based on the theory of anisotropic medium is used, and microwave diodes are added to the material. Where k is the incident direction of the beam, E is the polarization direction of the electric field, and H is the polarization direction of the magnetic field.

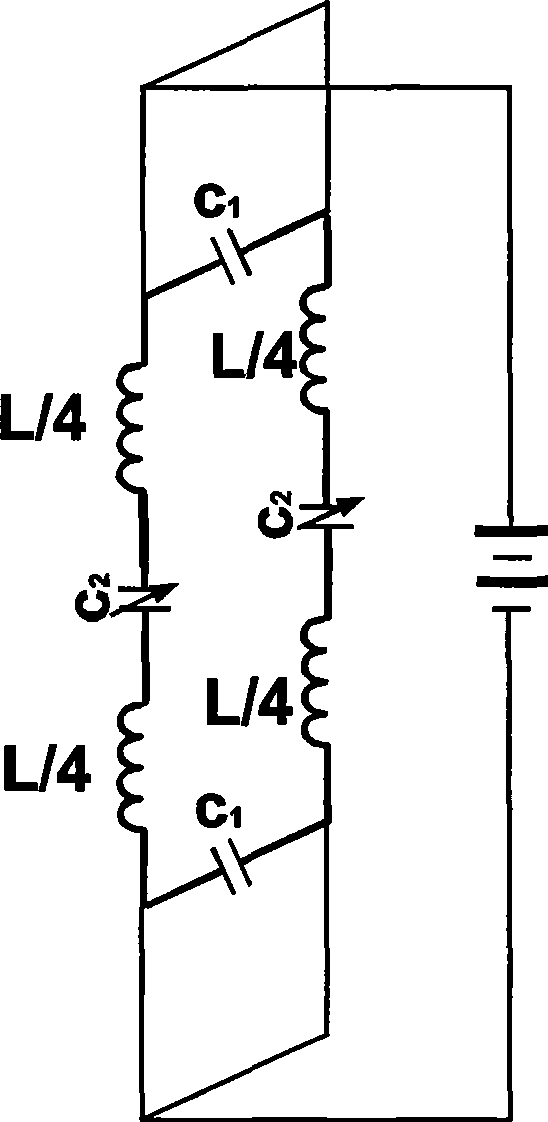

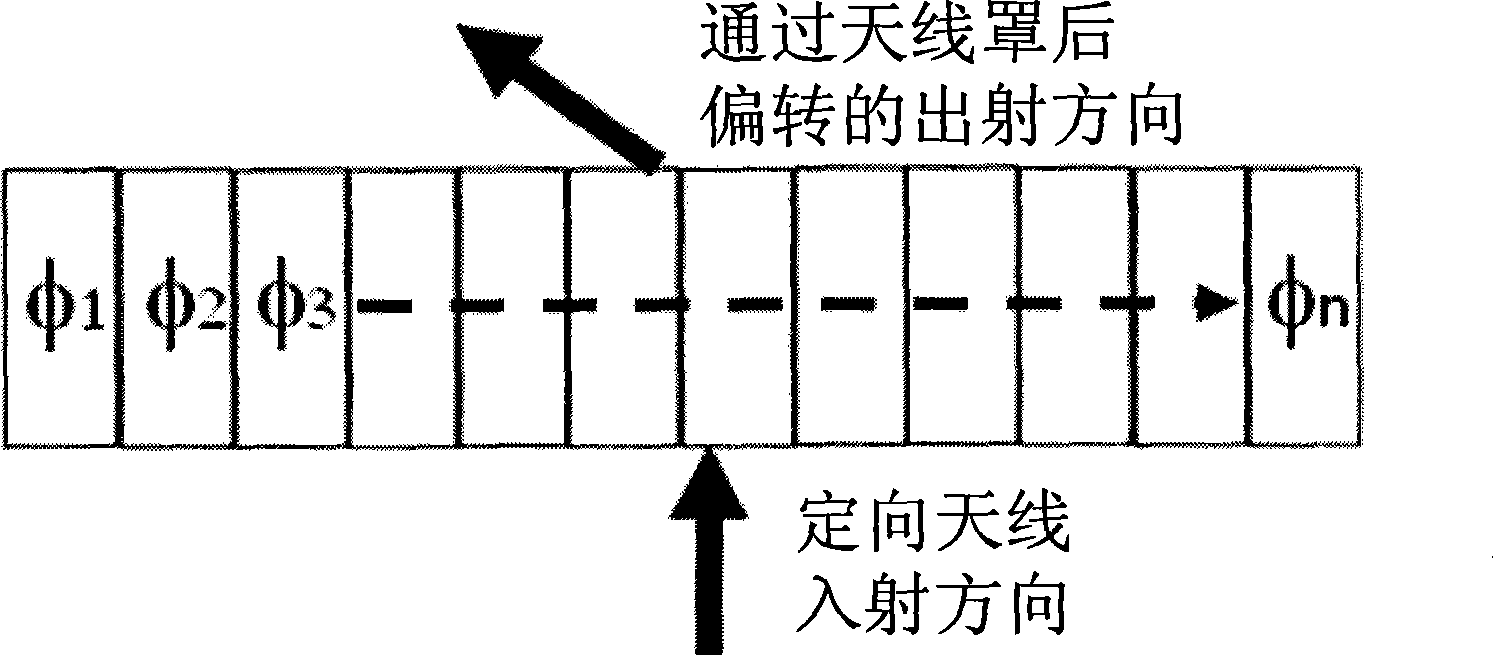

[0018] Such as figure 1 , image 3 As shown, the present invention prints I-shaped copper wires with the unit structure on the front and back of the FR4 dielectric board, and prints n and m unit lengths respectively in the horizontal and vertical directions of the dielectric board to form n×m double-sided uniformly distributed I-shaped structures. Symmetrical anisotropic dielectric plate; microwave diodes are added to the I-shaped structure of each unit, and a DC voltage is applied to each unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com