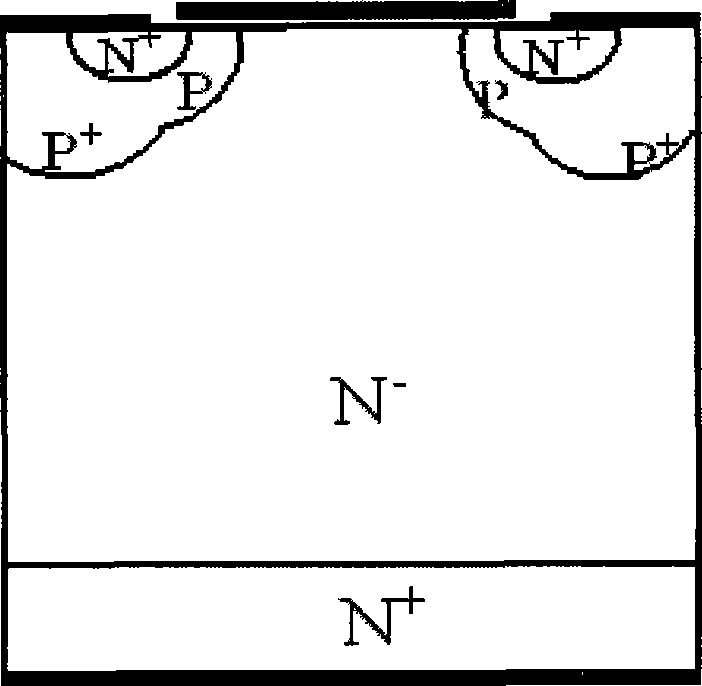

Manufacturing method for vertical DMOS device

An oxide semiconductor and vertical double-diffusion technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of cumbersome manufacturing process and high cost, so as to save manufacturing cost, reduce parasitic resistance, parasitic transistor The effect of weakening the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The manufacturing method of a vertical double-diffused metal oxide semiconductor device of the present invention greatly saves the manufacturing cost of the device, and effectively weakens the parasitic transistor effect of the device.

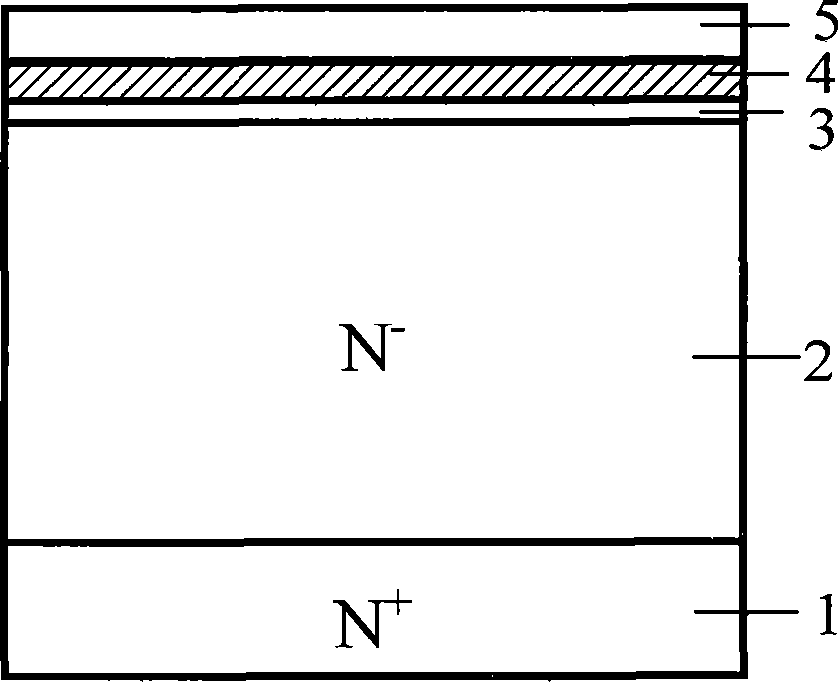

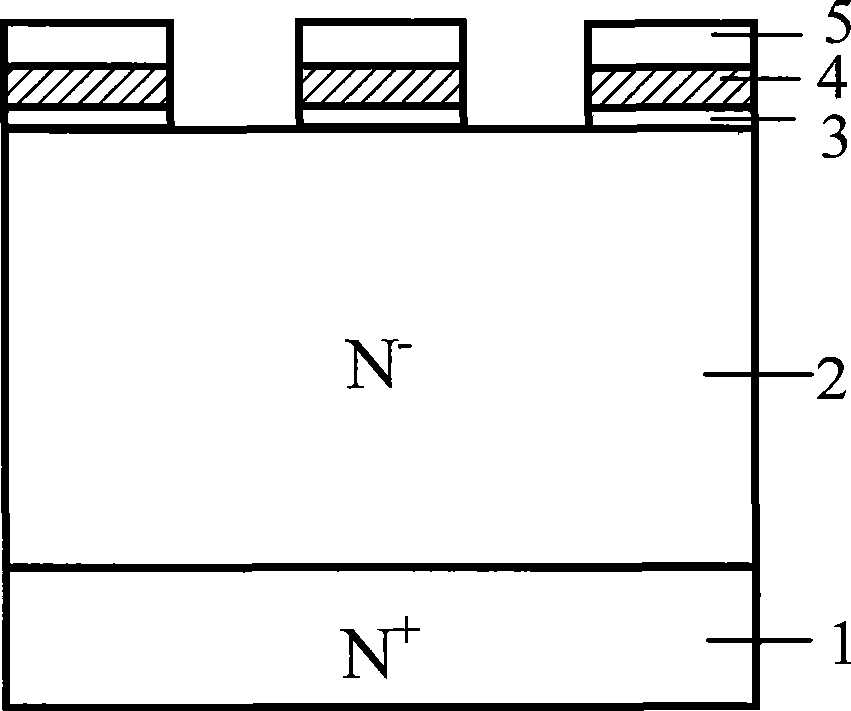

[0035] During specific implementation, for a low-voltage device, such as a 100V vertical double-diffused metal-oxide-semiconductor device, its specific implementation process includes: (1) in N + The growth concentration on the substrate was 1×10 15 cm -3 , with a thickness of 10 μmN - The epitaxial layer is then heated in an oxygen atmosphere at 1000°C for about 2 hours to grow an oxide layer of about 200nm, and then deposit polysilicon with a thickness of 800nm by chemical vapor deposition, and do arsenic doping while depositing, and the concentration of arsenic doping for 10 20 cm -3 order, and then generate silicon dioxide of about 500nm by heating in an oxygen atmosphere at 1000°C for about 30 minutes; (2) through the mask of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com