Production method of debitterized honey pomelo soybean yoghurt

A production method and technology of sour soy milk, applied in dairy products, food preparation, milk substitutes, etc., can solve the problems of not removing the bitterness of pomelo peel and loss of nutritional components, etc., achieve a good effect of removing bitterness, and improve the effect of comprehensive economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

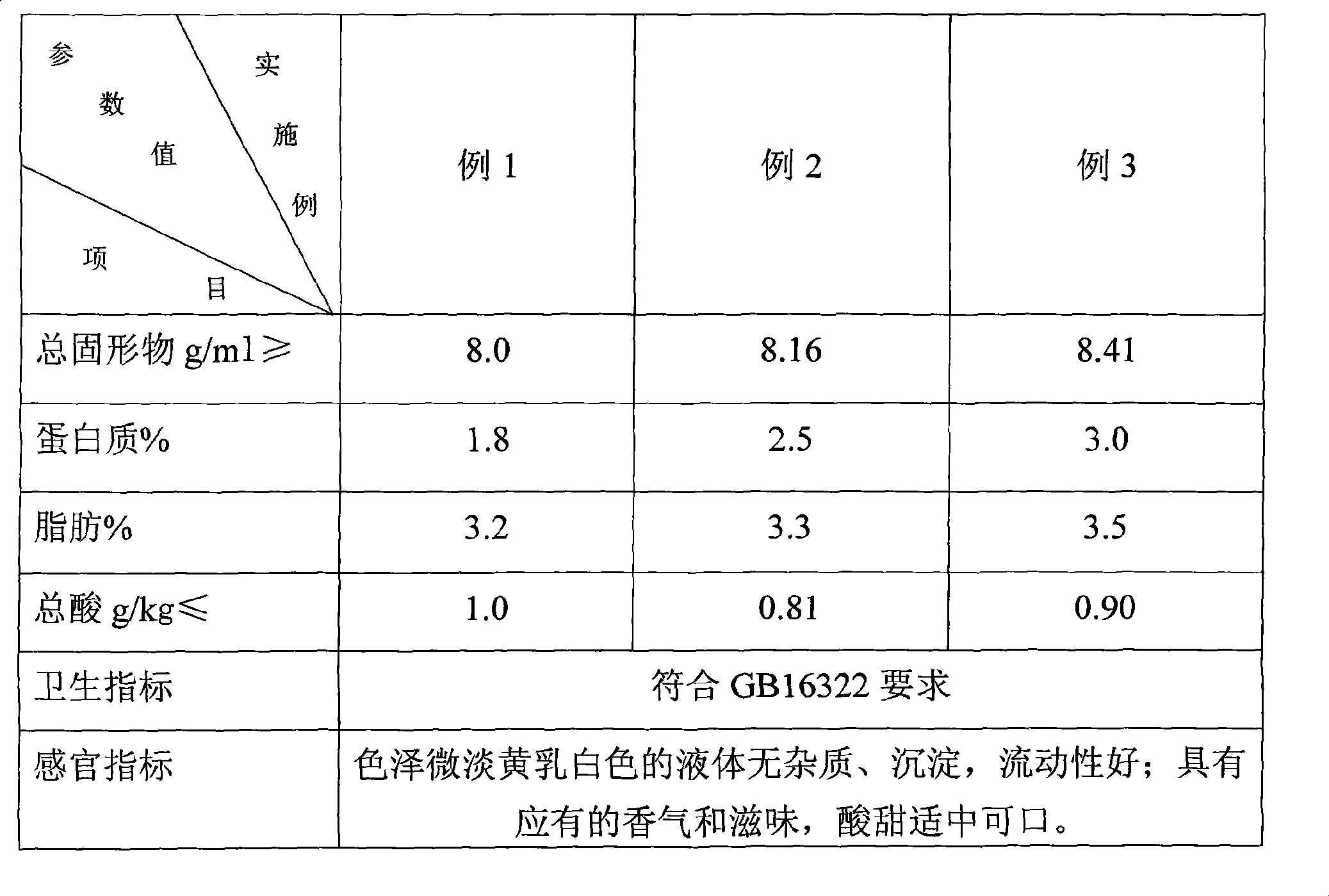

Embodiment 1

[0030] Soak 5kg of soybeans in water for 6-8 hours, then mix with 45kg of water, put them in a refiner to grind until all the soybeans are ground into soymilk, put the soymilk in a preheating tank to preheat to 55°C-65°C, At the same time, homogeneous, homogeneous soybean milk is placed in a sterilizing tank, heated to 95°C, and then kept warm for 15 minutes. Stir while keeping warm to become soybean milk. At the same time, vacuum degassing is carried out to remove the beany smell. In the tank, the protein content of soybean milk is determined to be 3.5-4.5% according to conventional methods;

[0031] Put 25kg of sterilized pomelo pulp used to make concentrated debittered honey pomelo pulp into 50kg of soy milk obtained, and debitterize at 55°C for 2 hours, then separate the debittered soymilk from the debittered pomelo pulp, separate The obtained pomelo pulp is used to make concentrated debittered pomelo pulp, and the pH value of the separated debittered soybean milk is adjus...

Embodiment 2

[0037] Soak 10kg of soybeans in water for 10 hours, mix them with 110kg of water, and put them in a refiner to grind until all the soybeans are ground into soymilk. Put the soymilk in a preheating tank to preheat to 65°C, and turn on the homogenizing pump at the same time. , Stir and shear the soybean milk in the preheating tank, place the preheated soybean milk in the sterilization tank, heat it to 100°C and keep it warm for 20 minutes, turn on the homogeneous pump for stirring and shearing while keeping warm, and turn on the vacuum pump regularly , remove the beany smell of soy milk in the tank, place the sterilized soy milk in a storage tank, store it for later use at a temperature of 90°C, and measure the protein content of the soy milk by conventional methods to be 2.1%;

[0038] Put 44kg of the sterilized pomelo meat capsule coating used to make the debittered honey pomelo dietary fiber into the obtained 120kg soybean milk, debitterize at 60°C for 3 hours, and then mix th...

Embodiment 3

[0041] Soak 100kg of soybeans in water for 12 hours, mix them with 900kg of water, and put them in a refiner to grind until all the soybeans are ground into soymilk. Preheat the soymilk in a preheating tank to 90°C, and turn on the homogenizing pump at the same time. , Stir and shear the soymilk in the preheating tank, put the preheated soymilk in the sterilizing tank, heat it to 100°C and keep it warm for 20 minutes, turn on the homogeneous pump to stir and shear it while keeping it warm, and it becomes soymilk, and Turn on the vacuum pump regularly to remove the beany smell of the soy milk in the tank. The sterilized soy milk is placed in the storage tank and stored at a temperature of 95°C for later use. The protein content of the soy milk is 3.3% as measured by conventional methods;

[0042] Put 350kg of sterilized honey pomelo sponge body with skin into 1000kg soy milk, heat it at 66°C for 4 hours to remove bitterness, and then mix the debitter soymilk with the skin of pom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com