Musca domestic pupae natural antimicrobial peptide products and preparation method and use thereof

A natural antibacterial and housefly pupa technology, applied in the preparation method, application, and cosmetic preparations of peptides, can solve the problems of low yield of antibacterial peptides, difficulty in large-scale production and preparation, and long process cycle, and reach the distribution range Broad, not easy to drug resistance, broad antibacterial spectrum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

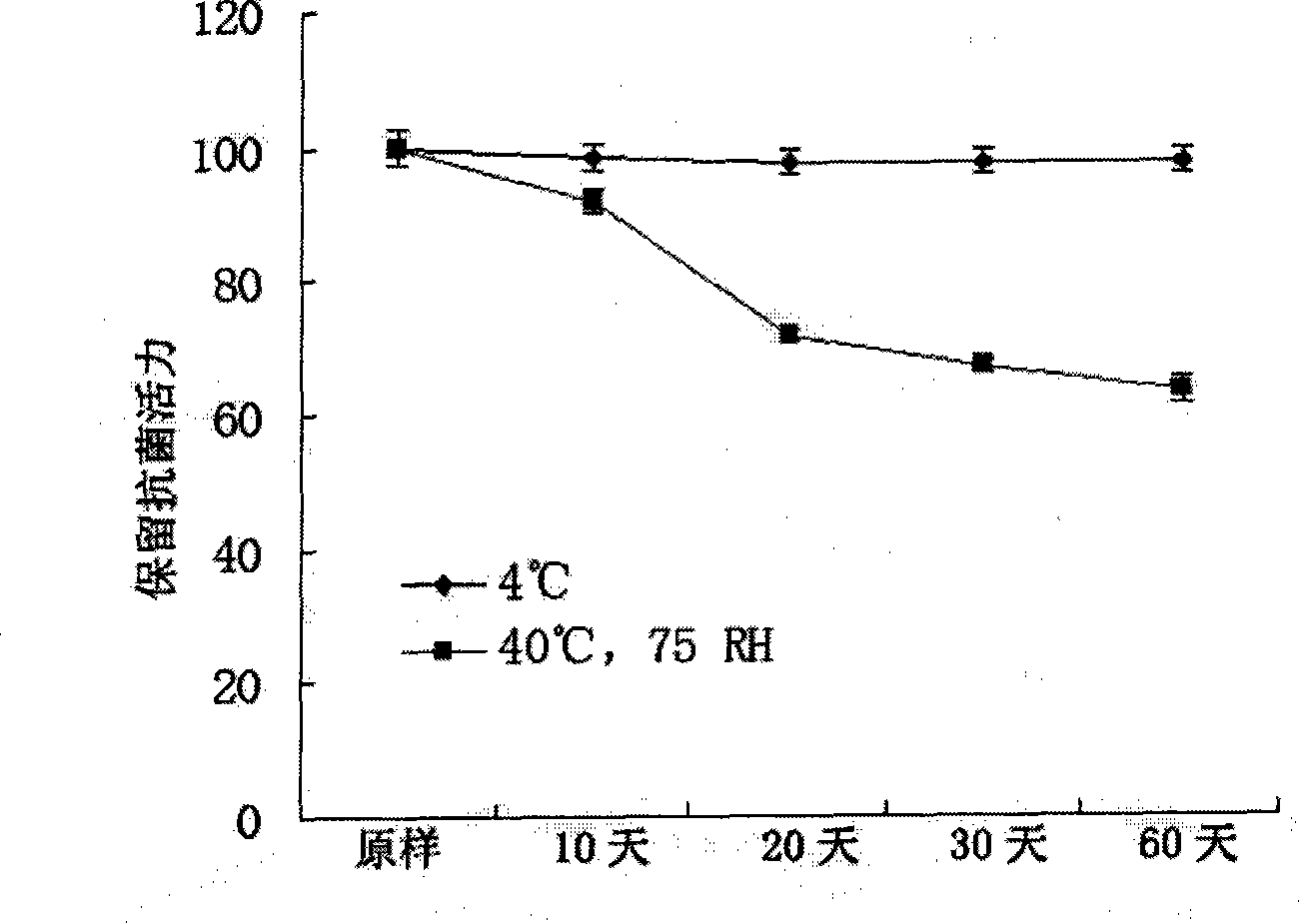

[0037] 1. Preparation of natural antimicrobial peptide products from housefly pupae

[0038] Specifically include the following steps:

[0039] (1) Weigh a certain amount of housefly pupae, wash with distilled water and dry, add the corresponding volume of 4°C pre-cooled 0.1M acetic acid solution according to the volume-to-weight ratio of 1ml:4g, homogenate, extract overnight at 4°C, and then place Heat treatment in a water bath at 90°C for 25 minutes, and then centrifuge at 4°C and 8000×g for 25 minutes to collect the supernatant, which is the crude extract of housefly pupae. After precipitation and drying (100°C), it is crushed into powder, which is one of the by-products of this process—insect protein powder for feed.

[0040] (2) Step (1) gained housefly pupa crude extract is filtered with 300 mesh sieves, and the filtrate is collected;

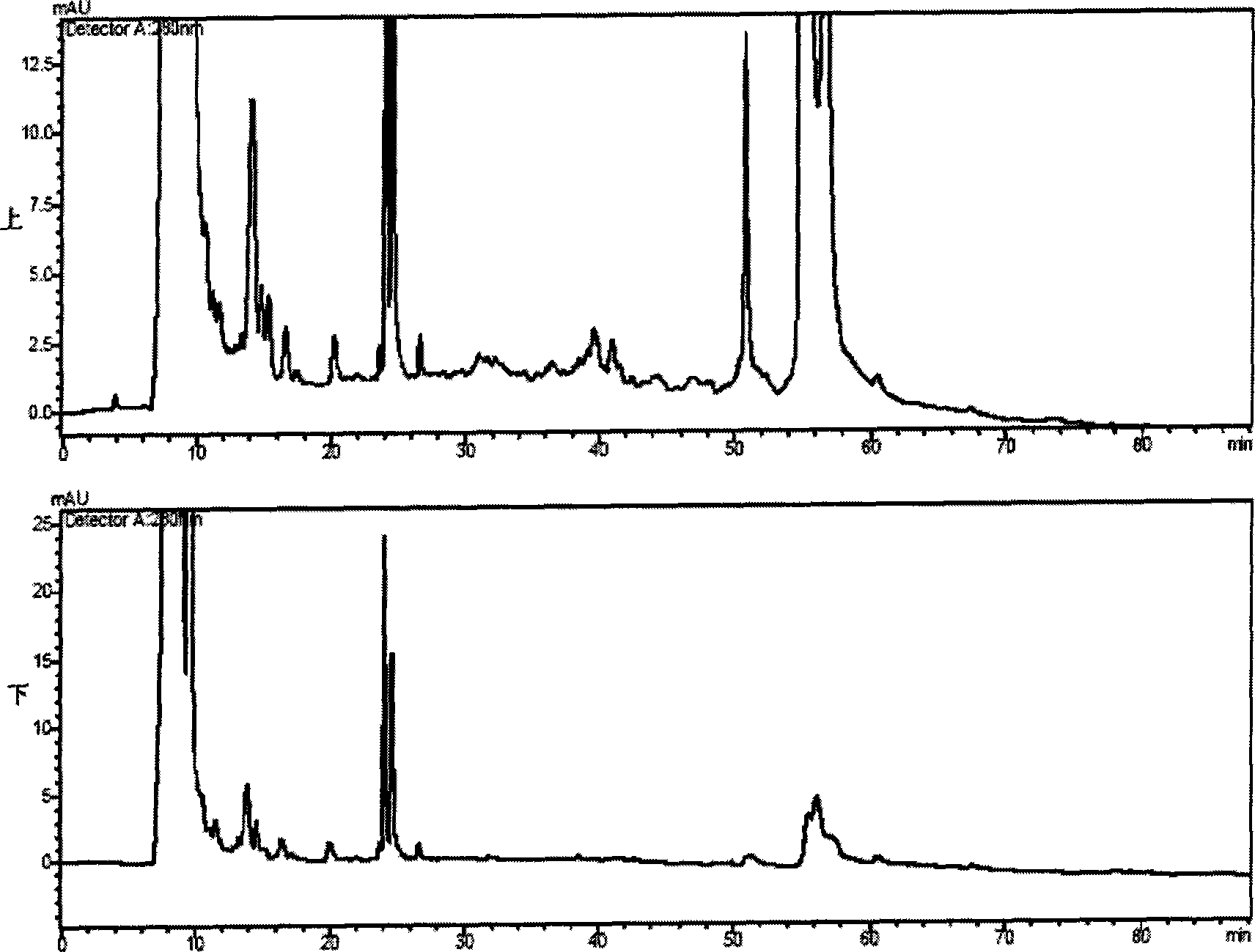

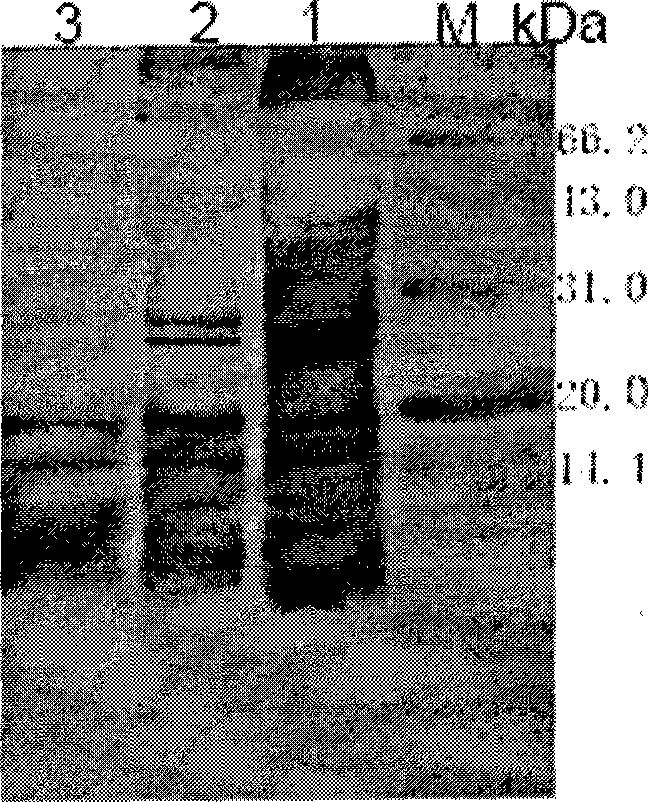

[0041] (3) The filtrate obtained in step (2) is loaded on an Amicon ultra-rate device (MW50,000, Millipore Company), centrifuged at 3,...

Embodiment 2

[0064] (1) Take a certain amount of housefly pupae, wash and dry with distilled water, add a corresponding volume of 8°C pre-cooled 0.3M acetic acid solution in a volume-to-weight ratio of 1ml:6g, homogenize, extract overnight at 8°C, and place Heat treatment in a water bath at 100°C for 35 minutes, then centrifuge at 6°C and 10,000×g for 35 minutes, and collect the supernatant, which is the crude extract of housefly pupae. After precipitation and drying (110°C), it is crushed into powder, which is one of the by-products of this process—insect protein powder for feed.

[0065] (2) Step (1) gained housefly pupa crude extract is filtered with 500 mesh sieves, and the filtrate is collected;

[0066] (3) The filtrate obtained in step (2) is loaded on an Amicon ultra-rate device (MW30,000, Millipore Company), centrifuged at 5,000×g for 40 minutes at 6°C in a centrifuge with a fixed rotation angle of 35 degrees, and the retained fractions are collected separately and filtered part ...

Embodiment 3

[0070] (1) Weigh a certain amount of housefly pupae, wash and dry with distilled water, add the corresponding volume of 0.2M acetic acid solution pre-cooled at 6°C in a volume-to-weight ratio of 1ml:5g, homogenize, extract overnight at 6°C, and place Heat treatment in a water bath at 95°C for 30 minutes, then centrifuge at 5°C and 9000×g for 30 minutes, and collect the supernatant, which is the crude extract of housefly pupae. After precipitation and drying (105°C), it is crushed into powder, which is one of the by-products of this process—insect protein powder for feed.

[0071] (2) Step (1) gained housefly pupa crude extract is filtered with 400 mesh sieves, and the filtrate is collected;

[0072](3) The filtrate obtained in step (2) is loaded on an Amicon ultra-rate device (MW30,000, Millipore Company), centrifuged at 5°C and 4,000×g for 30 minutes in a centrifuge with a fixed rotation angle of 35 degrees, and the retained parts are collected separately and filtered part o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com