Method for detecting cyanolabe in textiles by reversed phase high performance liquid chromatography

A technology of reversed-phase high-performance liquid chromatography and high-performance liquid chromatography, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as differences in the applicability of carcinogenic aromatic amines, uncertain conversion rates, and difficult judgments, so as to ensure accurate Good linearity, high extraction and separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] 1Experimental instruments and reagents

[0079] 1.1 Experimental equipment:

[0080] Japan Shimadzu LC-10AT high performance liquid chromatograph, Kromsil ODS-1C18, 5μm, 250mm×4.6mm column; SPD-10A UV detector, SCL-10A recorder, KQ-500DE CNC ultrasonic cleaner, electric drum Air drying oven. FINNIGAN LCQ DECA XP MAX LC / MS.

[0081] 1.2 Drugs and reagents:

[0082]

[0083] C 39 H 23 ClCrN 7 O 12 S·2Na standard sample (93% purity).

[0084] 2 Sample preparation

[0085] 2.1 Extraction sample preparation:

[0086] Cut a single dyed textile sample into small pieces of 3.5 cm x 3.5 cm. The weighed weight was 0.5421 g. Put the sample in a 50mL colorimetric tube, add 15mL methanol:water=70:30 mixed solution, place it in an ultrasonic bath with a frequency of 400W, and extract at (60±2)℃ for 30min. The extract was cooled at room temperature and filtered through a 0.45 μm pore size polytetrafluoroethylene membrane filter. Excessive contact with other plastic pol...

Embodiment 2

[0109] The difference from Example 1 is:

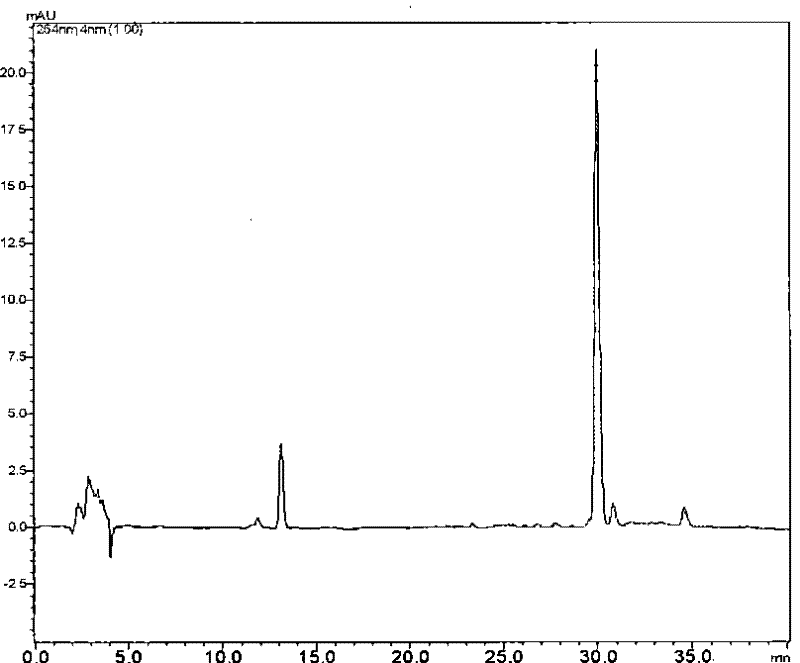

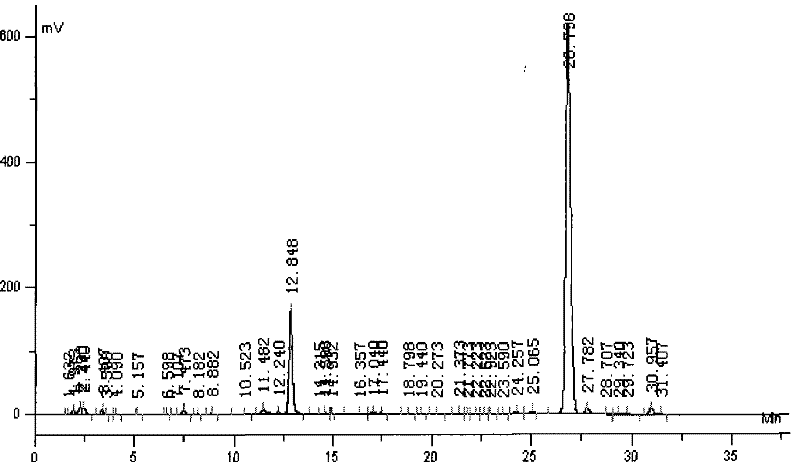

[0110] Standard curve: respectively measure 0.201mg / ml, 0.100mg / ml, 0.080mg / ml, 0.060mg / ml, 0.040mg / ml and 0.020mg / ml standard solutions prepared in Example 1 2.2 and inject 20μl into the liquid chromatography The standard solution was prepared according to the above method and measured by reversed-phase high performance liquid chromatography, and the peak area was measured at a wavelength of 254 nm. Taking the concentration as the abscissa and the peak area as the ordinate, draw a standard curve ( Image 6 ).

[0111] The resulting regression equation is:

[0112] (2) Y=aX+b, (a=3.703613e-008, b=2.870155e-003), R=0.9996135

[0113] Determination of the content of blue pigment in the sample to be tested: take the actual sample prepared in 2.1, and perform high performance liquid chromatography determination under the chromatographic conditions of 3.1: the peak area is 1405145, select the standard curve (2), and the measured concent...

Embodiment 3

[0115] 1 The experimental instruments and reagents are the same as those in Example 1

[0116] 2 Sample preparation

[0117] 2.1 Extraction sample preparation:

[0118] Cut a single dyed textile sample into small pieces of 3.5 cm x 3.5 cm. The weighed weight was 0.5562 g. Place the sample in a 50mL colorimetric tube, add 15mL methanol:water=80:20 mixed solution, place it in an ultrasonic bath with a frequency of 450W, and extract at (70±2)°C for 30min. The extract was cooled at room temperature and filtered through a 0.45 μm pore size polytetrafluoroethylene membrane filter. Excessive contact with other plastic polymers should be avoided during filtration. Pour the extract into a 1mL sample bottle, tighten the Teflon cap, and save it for later use.

[0119] 2.2 Standard sample preparation is the same as that in Example 1

[0120] 2.3 Mobile phase equipment:

[0121] Mixed solution of potassium dihydrogen phosphate and potassium phosphate: Weigh 2.60 g of potassium dihyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com