Gas diffusion layer used for fuel cell with proton exchange film, production and application thereof

A technology of gas diffusion layer and proton exchange membrane, which is applied to fuel cell components, solid electrolyte fuel cells, fuel cells, etc., can solve problems such as difficult to eliminate, low capillary pressure, and easy to be accumulated inside the base layer, etc., to achieve Improving battery performance and reducing the effect of mass transfer polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

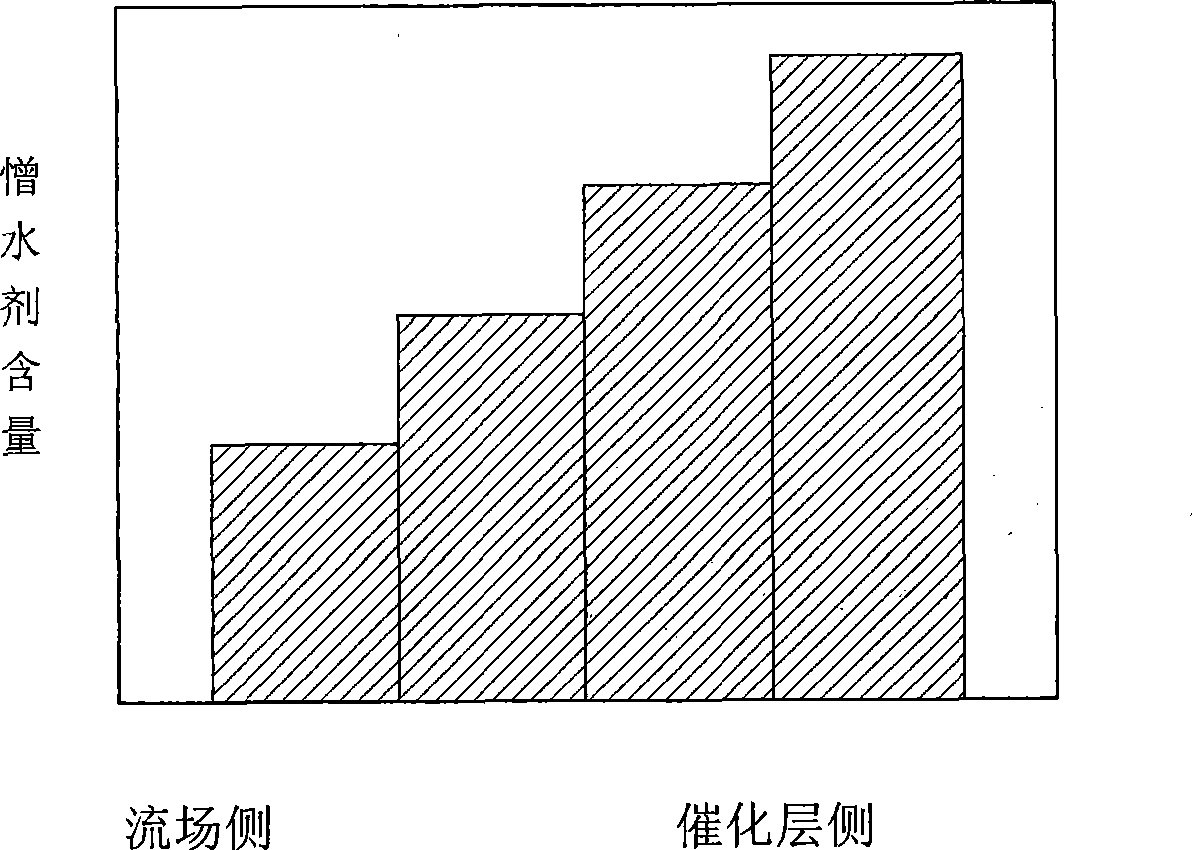

Method used

Image

Examples

Embodiment 1

[0033] Take 100mg of 60% PTFE emulsion, add 5.9g of deionized water, and ultrasonically vibrate for 10 minutes to prepare a uniformly dispersed water-repellent slurry, and then spray the slurry evenly on one side of the cut carbon paper, and spray in multiple layers. The next layer was sprayed after drying the first layer, weighed so that the total water-repellent mass percentage in the base layer was 10wt.%, and finally the prepared gas diffusion base layer was placed in a high-temperature firing furnace and incubated Burn for 30 minutes. Prepare the prepared gas diffusion base layer according to the traditional method to prepare the upper microporous layer as the gas diffusion layer, and finally place the prepared cathode and anode diffusion layers on both sides of the proton exchange membrane with the catalytic layer, at 120 ° C, 1.0 Under the condition of MPa, hot press for 30 minutes to make a membrane-electrode three-in-one assembly. Place this component on both sides o...

Embodiment 2

[0037] Take 100mg of 60% PTFE emulsion, add 5.9g of deionized water, and ultrasonically vibrate for 10 minutes to prepare a uniformly dispersed water-repellent slurry, and then spray the slurry evenly on one side of the cut carbon paper, and spray in multiple layers. The next layer was sprayed after the layer was dried, weighed so that the total water repellent mass percentage in the base layer was 20wt.%, and finally the prepared gas diffusion base layer was placed in a high-temperature firing furnace, and incubated Burn for 30 minutes. A single cell was assembled according to the method of Example 1. Battery performance curve see Figure 6 .

Embodiment 3

[0039] Take 100mg of 60% PTFE emulsion, add 5.9g of deionized water, and ultrasonically vibrate for 10 minutes to prepare a uniformly dispersed water-repellent slurry, and then spray the slurry evenly on one side of the cut carbon paper, and spray in multiple layers. The next layer was sprayed after the layer was dried, weighed so that the total water-repellent mass percentage in the base layer was 30wt.%, and finally the prepared gas diffusion base layer was placed in a high-temperature firing furnace and incubated Burn for 30 minutes. A single cell was assembled according to the method of Example 1. Battery performance curve see Figure 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com