Pressurizing dissolved air flotation cleaning method for organic pollutant on reverse osmosis membrane

A technology of organic pollutants and reverse osmosis membranes, which is applied in the field of membrane separation in chemical engineering science, can solve the problems of increased operating costs of reverse osmosis membranes, high cost of cleaning chemicals, damage to reverse osmosis membranes, etc., to reduce the cost of membrane cleaning chemicals, Effects of reducing organic pollution and increasing air bubble adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

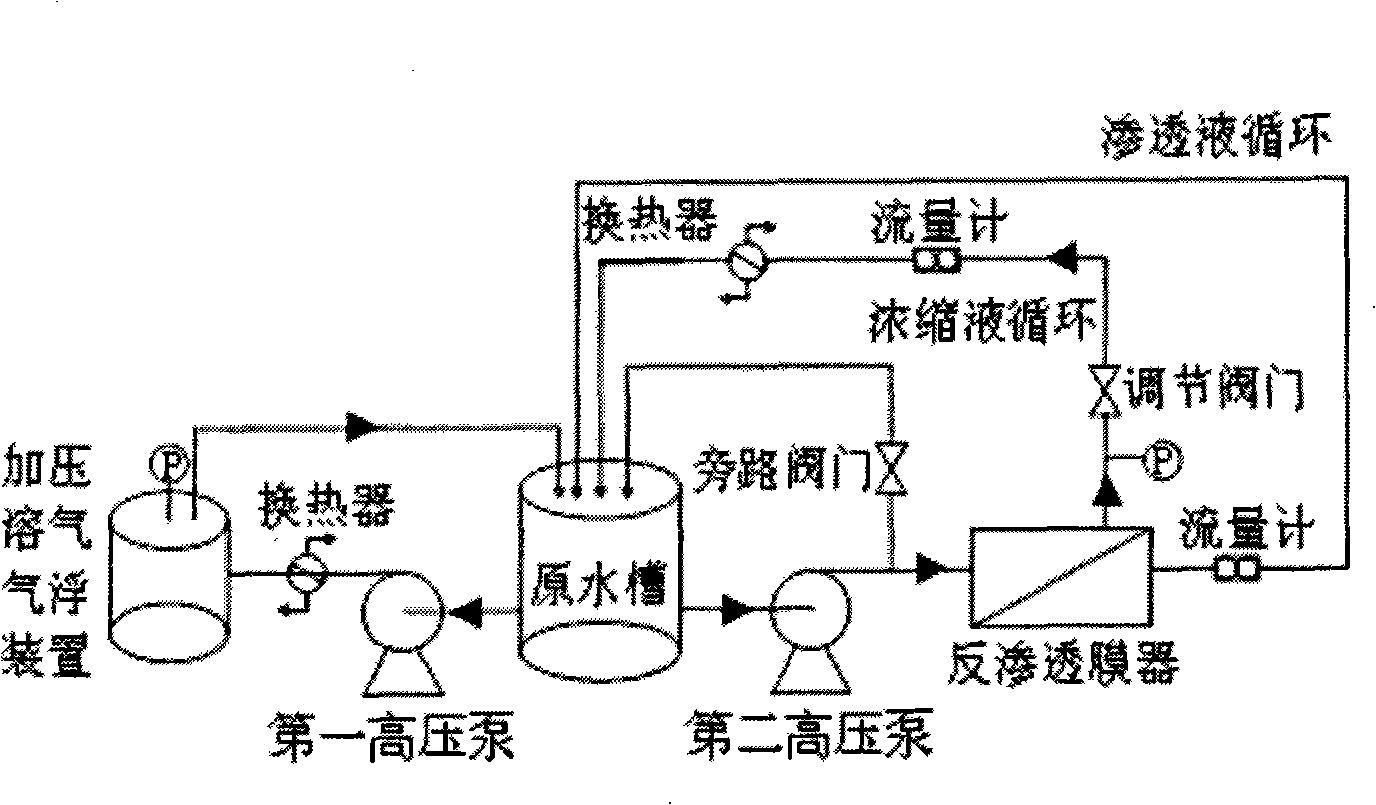

[0023] The whole system is divided into 2 sub-circulation systems, such as figure 1 Shown: One is a reverse osmosis membrane system, used for membrane fouling and membrane cleaning; the other is a gas-liquid mixing system, which generates a gas-liquid mixed cleaning solution through a pressurized dissolved air flotation device. Both systems share a raw water tank.

[0024] In the reverse osmosis membrane system, a low-pressure flat reverse osmosis membrane is used. The flat membrane is taken from the TW30-1812 membrane of Beijing Ande Membrane Separation Company, and the membrane area is 1.39×10 -2 m 2 . The reverse osmosis concentrate port is equipped with regulating valves, flow meters and heat exchangers, and all the concentrate from the reverse osmosis membrane is returned to the original water tank for circulation. Install a small-range flowmeter at the permeate port of the reverse osmosis membrane, and return all the permeate to the original water tank for circulation...

Embodiment 2

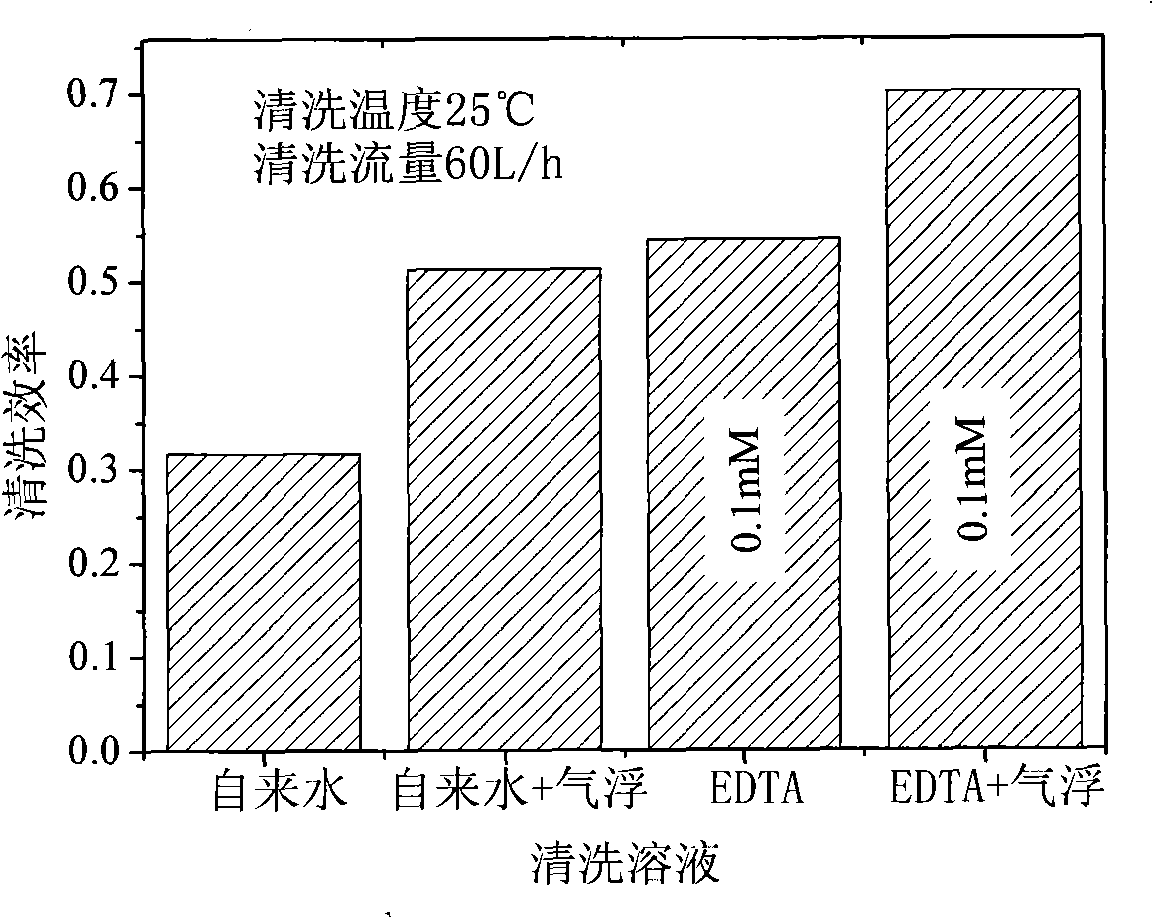

[0034] In this embodiment, the type of cleaning solution is changed to EDTA for testing. The system is equipped with figure 1 shown.

[0035] Activated carbon was used to filter tap water to test the initial water production Jv0 value of the reverse osmosis membrane before organic pollution occurred. During the test, the temperature was kept constant at 20°C and the pressure was kept constant at 1Mpa.

[0036] Weigh 0.8g humic acid powder, dissolve in ultrapure water, add concentrated hydrochloric acid solution to adjust pH=1, stir for one hour, make it fully mixed, then use NaOH solution to adjust pH=13, stir for one hour, After standing for two hours, filter twice with quantitative filter paper, filter out the undissolved humic acid sediment, pour the prepared humic acid solution into the original water tank, and add 8.88g CaCl 2 and 32.8gNaCl in the original water tank, adjust the pH to 4 with concentrated hydrochloric acid, prepare 10L pollution solution, and carry out t...

Embodiment 3

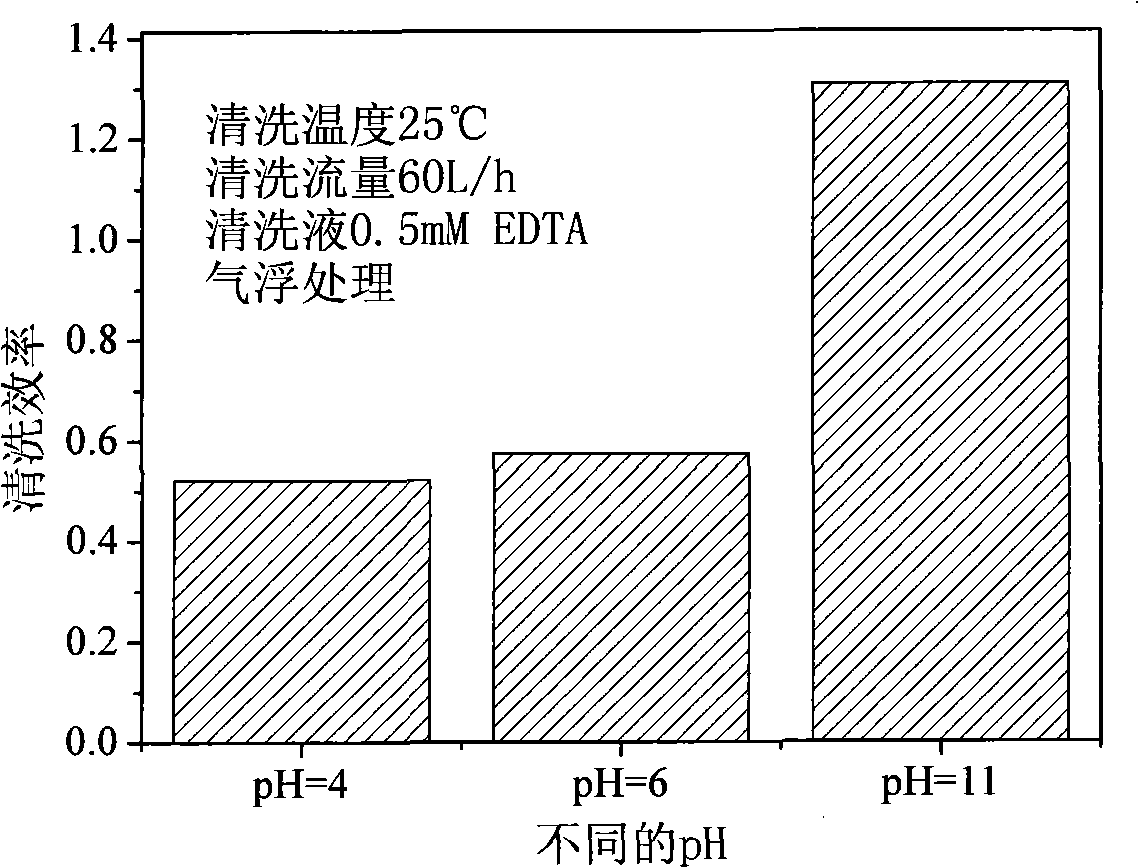

[0043] In this embodiment, the influence of the pH value of the cleaning solution on the cleaning efficiency is tested. The system is equipped with figure 1 shown.

[0044] Activated carbon was used to filter tap water to test the initial water production Jv0 value of the reverse osmosis membrane before organic pollution occurred. During the test, the temperature was kept constant at 20°C and the pressure was kept constant at 1Mpa.

[0045] Weigh 0.4g humic acid powder, dissolve in ultrapure water, add concentrated hydrochloric acid solution to adjust pH=1, stir for one hour, make it fully mixed, then use NaOH solution to adjust pH=13, stir for one hour, After standing for two hours, filter twice with quantitative filter paper, filter out the undissolved humic acid sediment, pour the prepared humic acid solution into the original water tank, and add 4.44g CaCl 2 and 16.4g NaCl in the original water tank, adjust the pH to 4 with concentrated hydrochloric acid, prepare 10L pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com