Stone oil sulphonic acid, its salt, preparation method and uses thereof

A technology of petroleum sulfonate and petroleum sulfonic acid, which is applied in the preparation of sulfonic acid, chemical instruments and methods, petrochemical modification, etc., can solve the problems of insufficient source of raw materials, unsatisfactory application performance, complicated preparation process, etc. The effect of low price, excellent performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, preparation petroleum sulfonate

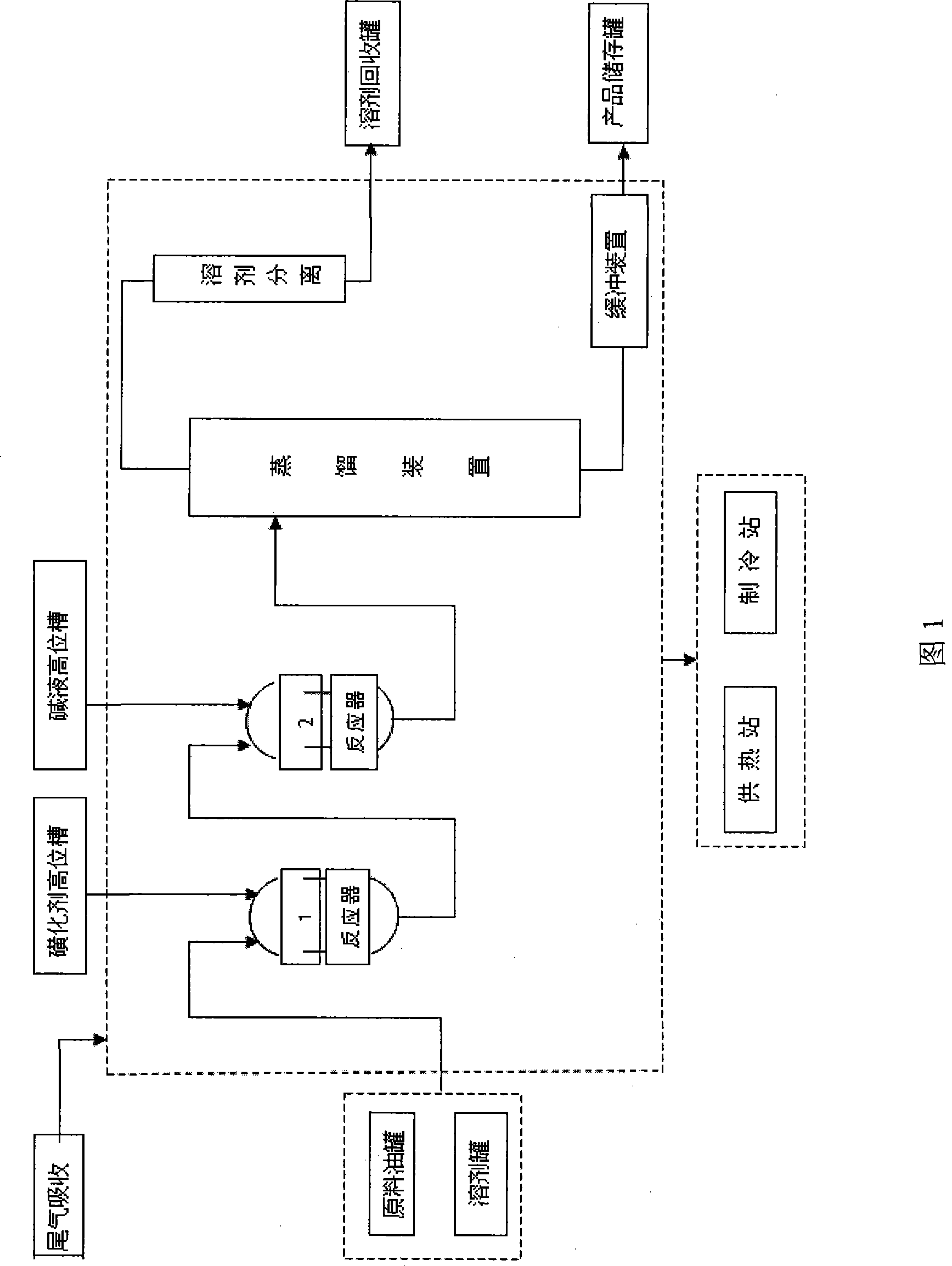

[0022] The sulfonating agent SO 3 600kg (30 parts by mass) pumped figure 1 Reserved in the high slot. 800kg (40 parts by mass) of raw oil fraction of Shengli Oilfield crude oil at 280-600°C, 300kg of OP-15 (15 parts by mass), solvent C 2 h 4 Cl 2 395kg (19.75 parts by mass) pumped in figure 1 In the reactor 1, the temperature is controlled at 15-20°C, and the sulfonating agent SO is added dropwise. 3 600kg. After the dropwise addition was complete, petroleum sulfonic acid was obtained, and stirring was continued for 120 minutes. The obtained petroleum sulfonic acid is then pumped into the reactor 2, and the temperature is raised to 60-70° C., and the aging reaction is carried out with stirring for 2 hours. 430kg ammoniacal liquor (mass percentage concentration 25%) in the lye head tank is added dropwise to figure 1 Neutralization reaction is carried out in the petroleum sulfonic acid in Reactor 2, the temperature...

Embodiment 2

[0066] Embodiment 2, preparation petroleum sulfonate

[0067] According to the steps of Example 1, take 473.6kg (59.2 parts by mass) of crude oil fraction of 280-600°C of Shengli Oilfield crude oil, 40kg (5 parts by mass) of OP-1540kg (5 parts by mass), 80kg (10 parts by mass) of petroleum ether, and dropwise add the sulfonating agent SO 3 80kg (10 parts by mass), after completing the sulfonation reaction, dropwise adding 160kg of ammonia water with a mass percentage concentration of 25% for neutralization reaction, so that the final pH of the system is 7-9; wherein, the temperature of the sulfonation reaction is 20-25 ℃. All the other are operated by the processing condition of embodiment 1, obtain 650kg finished petroleum sulfonate.

[0068] The composition of the prepared petroleum sulfonate product was analyzed and the properties were determined, the results are shown in Table 1.

Embodiment 3

[0069] Embodiment 3, preparation petroleum sulfonate

[0070] According to the steps of Example 1, 355.2Kg (44.4 parts by mass) of raw oil cuts at 280-600°C of Shengli Oilfield crude oil, OP-1580Kg (10 parts by mass), CH 2 Cl 2 120Kg (15 parts by mass), add sulfonating agent SO3 160Kg (20 parts by mass) dropwise, after completing the sulfonation reaction, add 160kg of ammonia water with a mass percentage concentration of 35% for neutralization reaction, so that the final pH of the system is 7-9 ; Wherein, the temperature of the sulfonation reaction is 25-30°C. All the other are operated by the processing condition of embodiment 1, obtain 700kg finished petroleum sulfonate.

[0071] The composition of the prepared petroleum sulfonate product was analyzed and the properties were determined, the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com