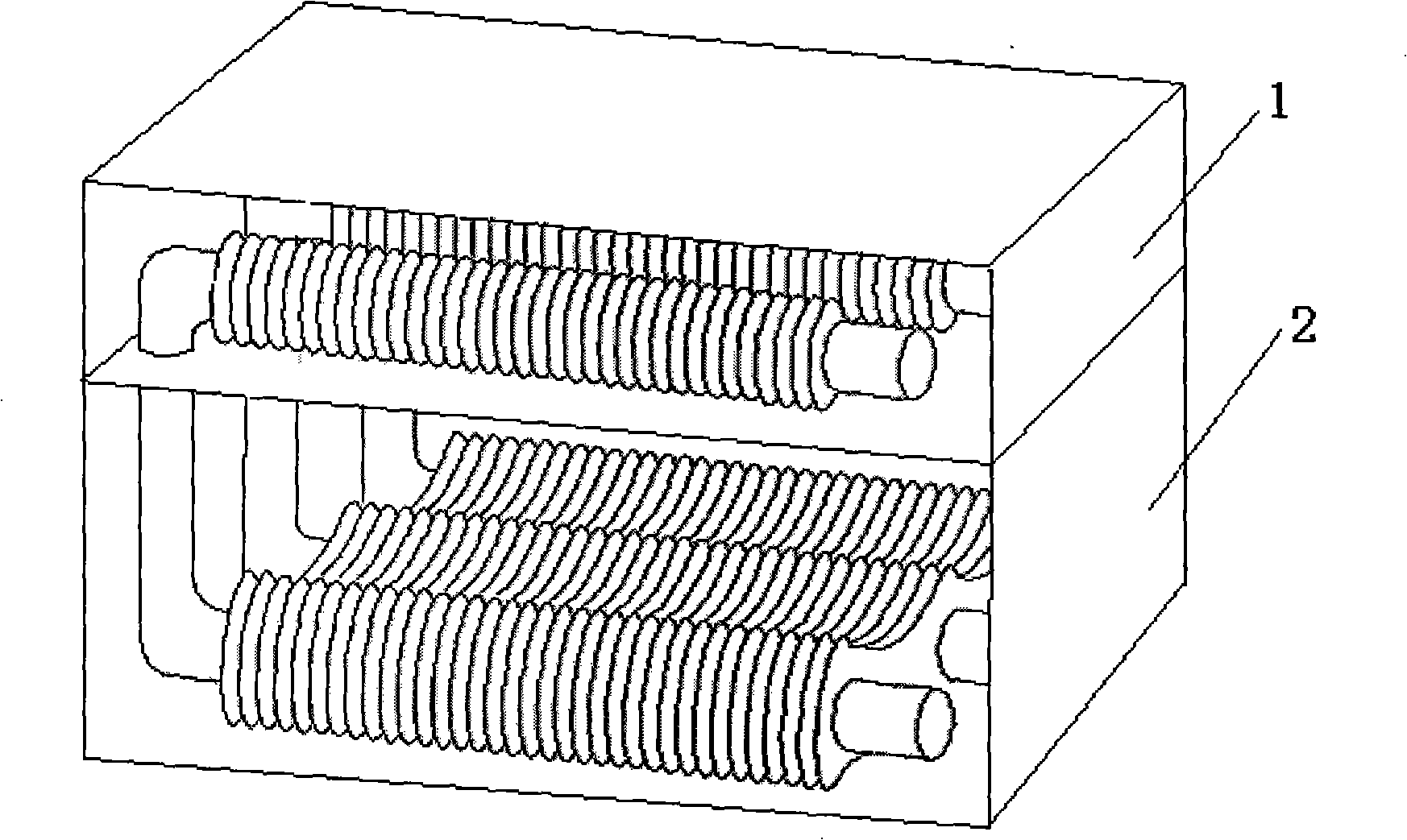

Composite anti-corrosion heat-exchanger by using flue gas to condense thermal energy

A technology of heat exchange device and flue gas condensation, which is applied in the direction of coating, etc., can solve the problems of abnormal operation of equipment systems, limitations of adaptability and economy, poor thermal conductivity of materials, etc., and achieve excellent heat transfer performance and practicability And economical improvement, the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

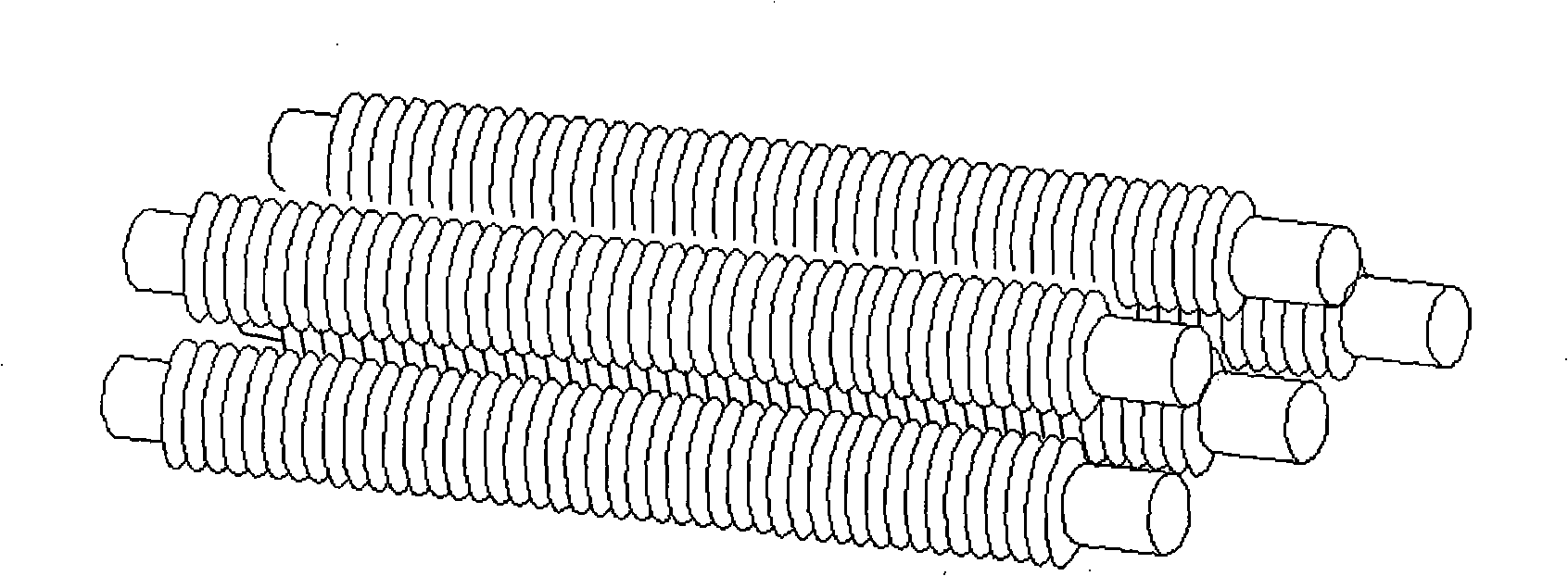

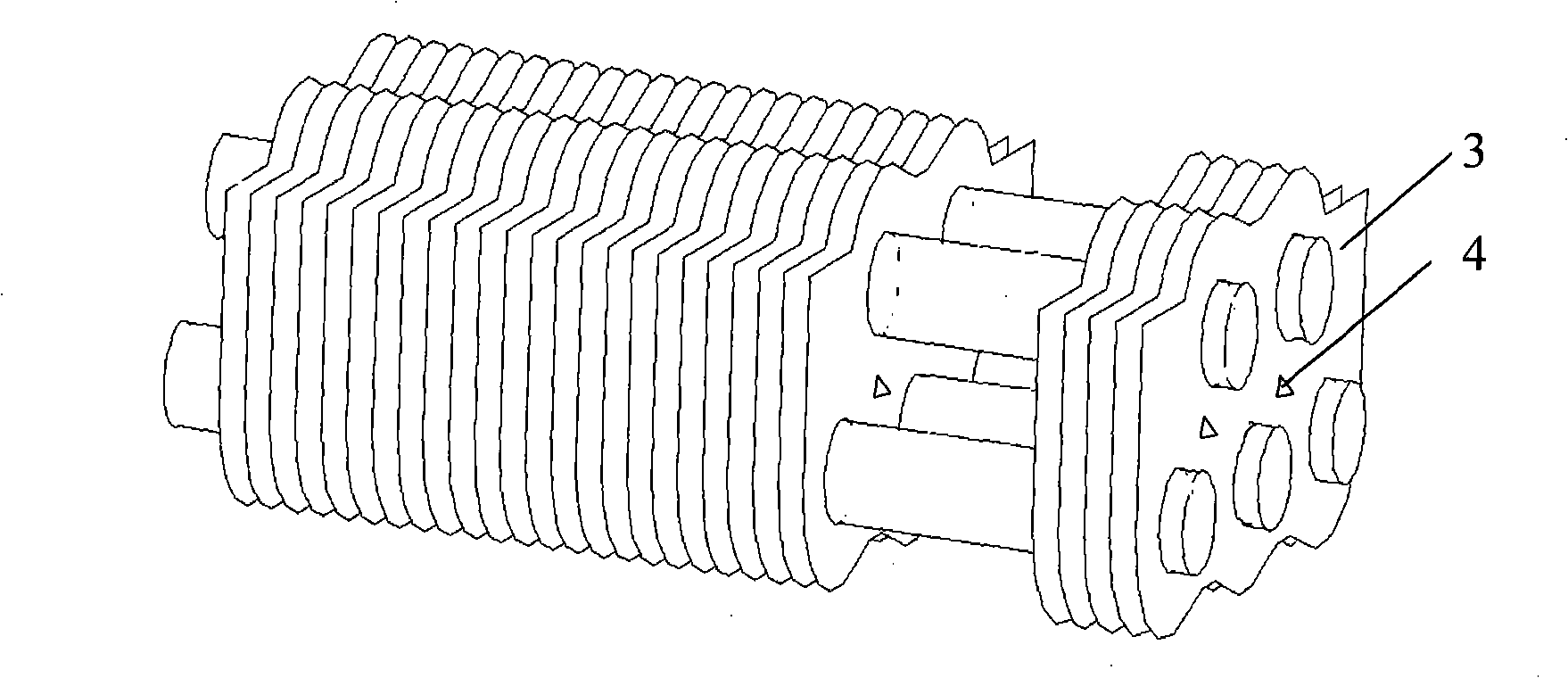

[0031] Example 1: The high-temperature heat exchange section 1 adopts stainless steel-aluminum composite tubes and aluminum alloy fins. The finned base pipe and fins of the low temperature heat exchange section 2 are made of red copper, the finned base pipe is a round tube, and the fins are provided with triangular pressure equalization holes; the upper and lower edges of the fins are arc-shaped, and the upper edge of the fins is arc-shaped The arc is gentler than the lower edge, and the height of the upper fins of the fin base tube is lower than that of the lower fins. Both the outer surface of the fin base tube and the surface of the fin are coated with an amorphous nickel-copper-phosphorus chemical composite coating with sodium molybdate as a stabilizer, and then coated with a fluororesin organic coating. The thickness of the chemical coating is 20 μm, the thickness of the organic coating is 20 μm, and the durability is 8 years.

Embodiment 2

[0032]Example 2: The heat exchange section 1 adopts stainless steel-aluminum composite tubes and aluminum alloy fins. The finned base tube and fins of heat exchange section 2 are made of red copper, the finned base tube is an oval tube, and the fins are provided with triangular pressure equalization holes; the upper and lower edges of the fins are arc-shaped, and the arc ratio of the upper edge of the fins is The arc of the lower edge is gentle, and the height of the upper fins of the fin base tube is lower than that of the lower fins. Both the outer surface of the fin base tube and the fin surface are coated with an amorphous nickel-copper-phosphorus chemical composite coating with sodium molybdate as a stabilizer, and then coated with a fluorocarbon resin organic coating. The thickness of the electroless coating is 30 μm, the thickness of the organic coating is 30 μm, and the durability is 10 years.

Embodiment 3

[0033] Example 3: The heat exchange section 1 adopts stainless steel-aluminum composite tubes and aluminum alloy fins. The finned base tube and fins of heat exchange section 2 are made of red copper, the finned base tube is an oval tube, and the fins are provided with circular pressure equalization holes; the upper and lower edges of the fins are arc-shaped, and the upper edge of the fins is arc-shaped The arc is gentler than the lower edge, and the height of the upper fins of the fin base tube is lower than that of the lower fins. An amorphous nickel-copper-phosphorus chemical composite coating with sodium molybdate as a stabilizer is plated on the outer surface of the fin base tube and the fin surface, and then coated with a polyurethane organic coating. The thickness of the electroless coating is 30 μm, the thickness of the organic coating is 30 μm, and the durability is 10 years.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com