Design method for coaxial bidirectional transmission direct-current high-temperature superconducting cable body

A two-way transmission, high temperature superconducting technology, applied in the field of power transmission and transformation of power systems, can solve the problems of low application efficiency and not the best method of superconducting tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

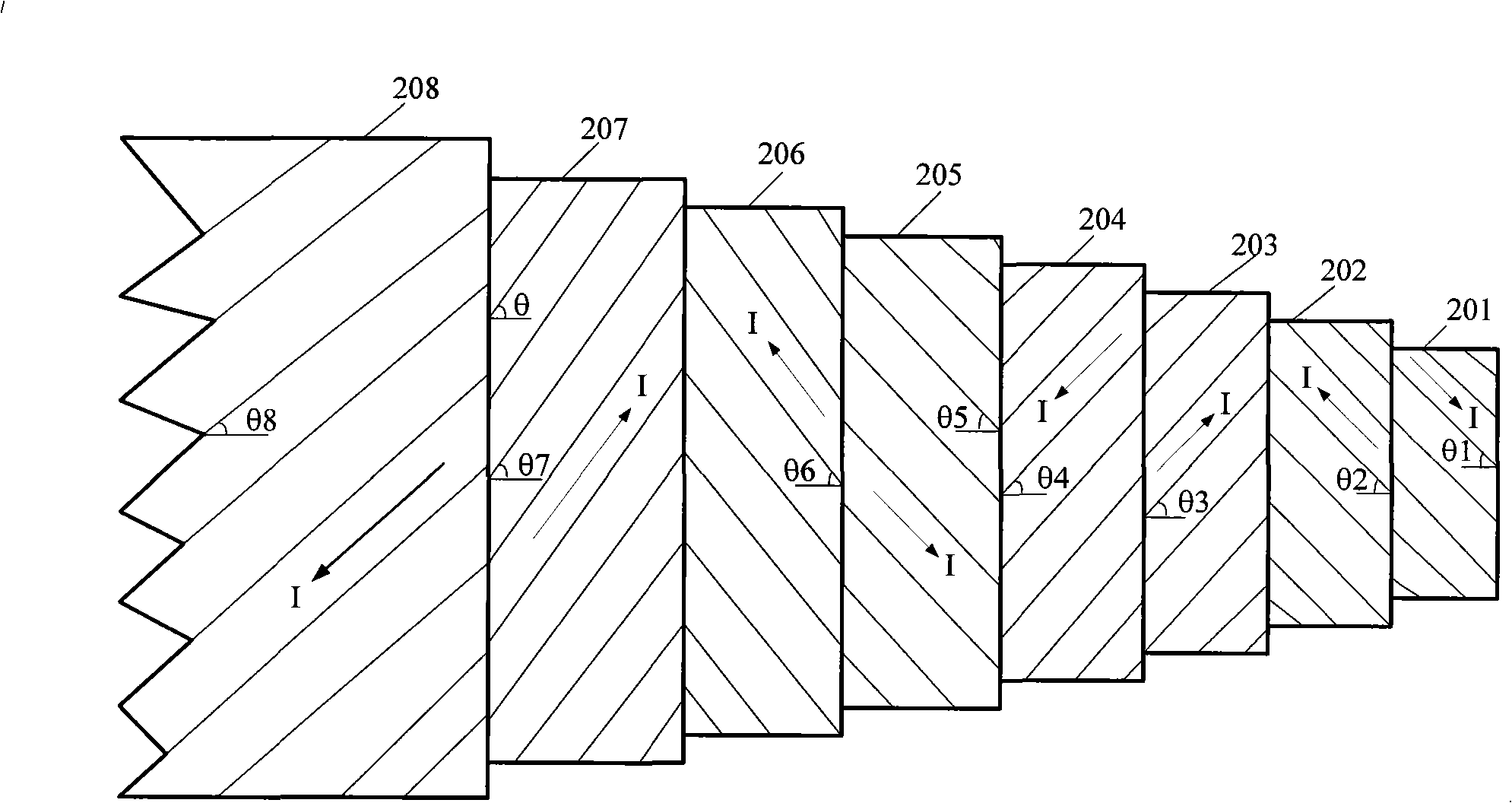

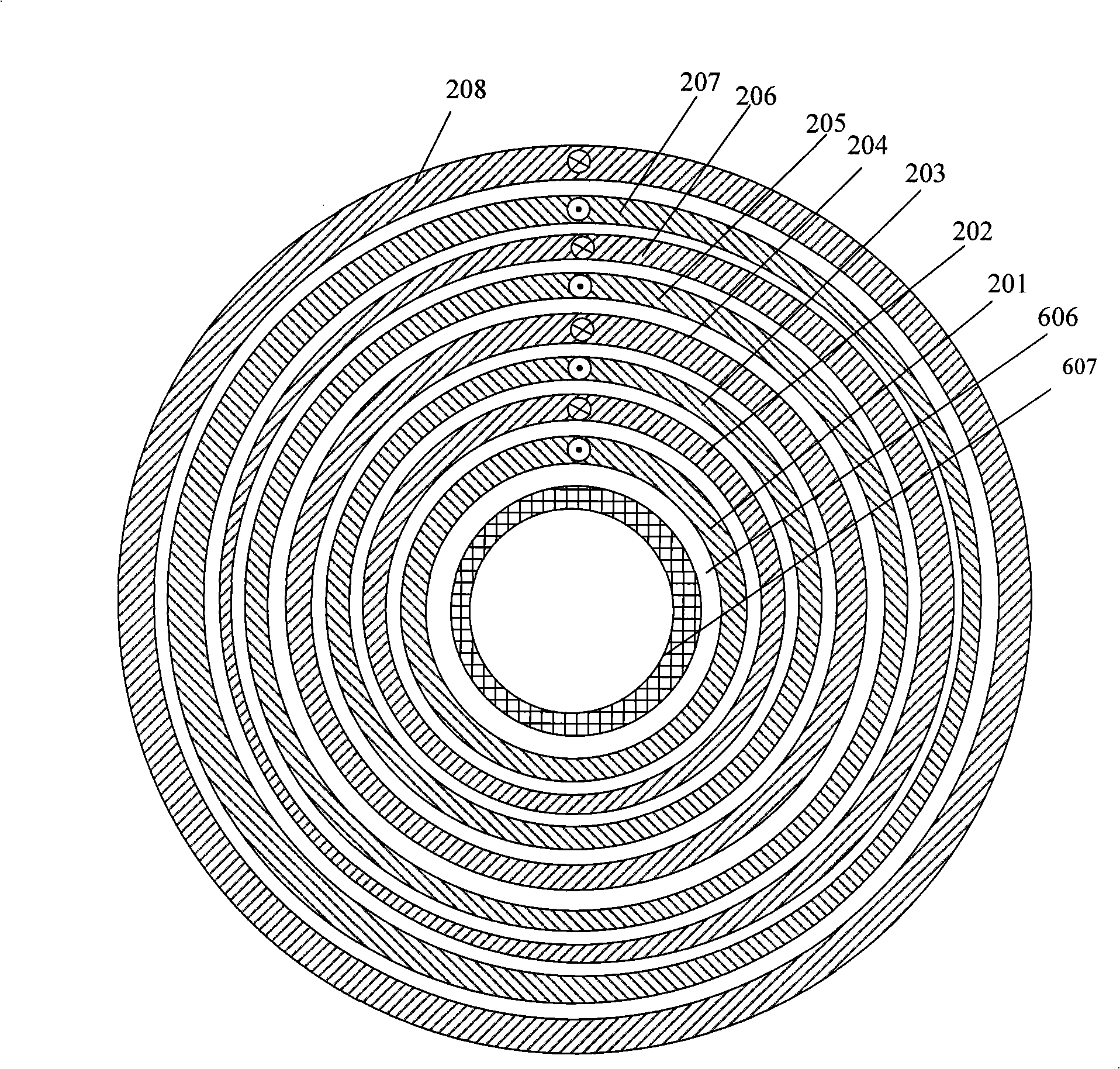

[0079] figure 2 It is a schematic diagram of an embodiment of a coaxial bidirectional current transmission superconducting cable body wound by eight layers of superconducting tapes. exist figure 2 Among them, 201 represents the first layer of superconducting tape, 202 represents the second layer of superconducting tape, 203 represents the third layer of superconducting tape, 204 represents the fourth layer of superconducting tape, and 205 represents the fifth layer of superconducting tape 206 is the sixth-layer superconducting tape, 207 is the seventh-layer superconducting tape, and 208 is the eighth-layer superconducting tape. Among them, the currents of layers 201, 203, 205 and 207 are in the same direction, which is the current removal; the currents of the layers 202, 204, 206 and 208 are in the same direction, which is the return current, and the interlayer insulation layer meets the insulation requirements. The winding helix angle θ in the figure refers to the angle b...

Embodiment 2

[0085] Figure 5 It is a schematic diagram of another embodiment of a coaxial bidirectional current transmission superconducting cable body wound with eight-layer superconducting tapes. exist Figure 5 Among them, 301 represents the first layer of superconducting tape, 302 represents the second layer of superconducting tape, 303 represents the third layer of superconducting tape, 304 represents the fourth layer of superconducting tape, and 305 represents the fifth layer of superconducting tape 306 is the sixth-layer superconducting tape, 307 is the seventh-layer superconducting tape, and 308 is the eighth-layer superconducting tape. The winding helix angle θ in the figure refers to the angle between the winding direction of the superconducting tape and the cable axis. Under the condition of a circular cross-section cable structure, the magnetic field is along the circumferential direction, that is, the magnetic field is parallel to the surface of the superconducting tape. Am...

Embodiment 3

[0093] Design example of coaxial bidirectional transmission DC high temperature superconducting cable,

[0094] Design requirements: rated current is 20kA, operating margin is 80%,

[0095] The design steps are:

[0096] Step 1. Design considerations:

[0097] ① Limit the strain suffered by the high-temperature superconducting tape due to thermal shrinkage and bending of the superconducting tape;

[0098] ②The magnetic field acting on the single strip should be minimized in order to reduce the I c degree of degradation;

[0099] ③Coaxial bidirectional transmission DC superconducting cable layers are subjected to the smallest magnetic field, and the critical current degradation is the smallest, which improves the utilization rate of high-temperature superconducting strips.

[0100] Step 2. Selection of layers of coaxial bidirectional transmission DC high temperature superconducting cable:

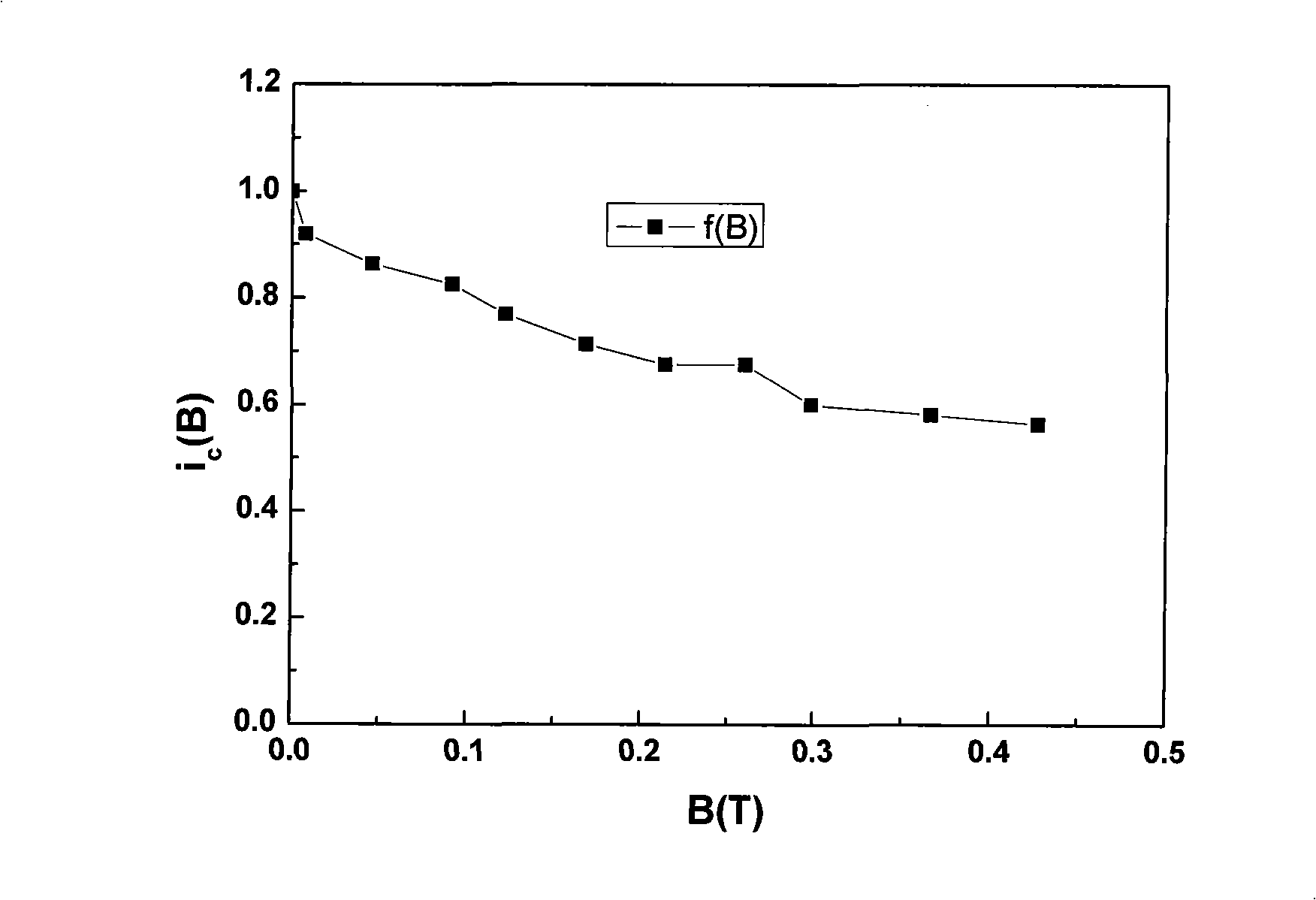

[0101] ① Electromagnetic properties of high-temperature superconducting strip: Sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical current | aaaaa | aaaaa |

| Minimum bending radius | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com