Apparatus for electrochemically synthesizing borohydride

A borohydride, electrochemical technology, applied in borane/diborane hydride, electrolysis process, electrolysis components, etc., can solve the problems of reduced current efficiency, low current efficiency, large footprint, etc. Current efficiency, high current efficiency, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

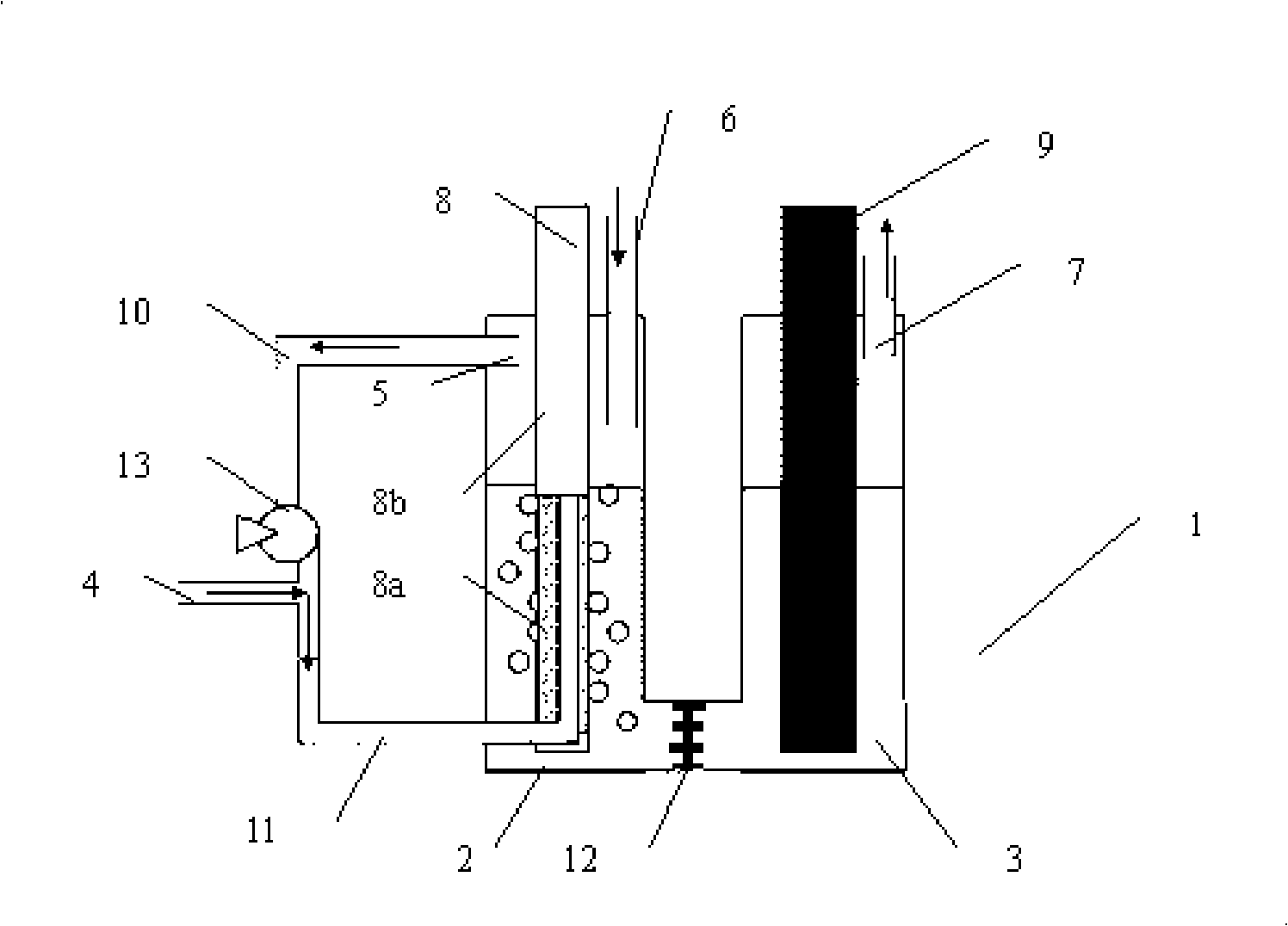

[0030] Such as figure 1 Shown, a kind of electrolysis prepares the device of sodium borohydride, comprises the quartz glass electrolytic cell 1 that cathode chamber 2 and anode chamber 3 constitute, and wherein cathode chamber 2 and anode chamber 3 are separated by porous alumina ceramic sheet 12; Described The upper part of the cathode chamber 2 is provided with a hydrogen outlet 5 and NaBO 2 and NaAlO 2 feed port 6, the side of the cathode chamber is provided with a hydrogen inlet 4, and the top of the anode chamber is provided with an oxygen outlet 7; the aluminum cathode 8 and the graphite anode 9 are respectively located inside the cathode chamber 2 and the anode chamber 3, with the electrolyte interface as limit, the aluminum cathode 8 is divided into upper and lower parts, the lower half 8a is a porous foam structure, and the upper half 8b is a solid structure, and Na is added to the cathode chamber 2 and the anode chamber 3 at the same time 3 AlF 6 and NaAlF 4 (SAF...

Embodiment 2

[0032] Such as figure 1 Shown, a kind of device of preparing potassium borohydride by electrolysis comprises the alumina ceramic electrolytic cell 1 that cathode chamber 2 and anode chamber 3 constitute, and wherein cathode chamber 2 and anode chamber 3 are separated by porous silicon dioxide ceramic sheet 12; The top of the cathode chamber 2 is provided with a hydrogen outlet 5 and a KBO 2and KAlO 2 Feed port 6, the side of the cathode chamber is provided with hydrogen inlet 4, the top of the anode chamber is provided with oxygen outlet 7; iron cathode 8 and graphite anode 9 are respectively located in the inside of cathode chamber 2 and anode chamber 3, simultaneously to the cathode chamber 2 and anode chamber 3 by adding K 3 AlF 6 、K 7 B 3 o 8 and NaAlF 4 , AlF 3 and CaF 2 , KBO 2 and KAlO 2 The solution is fed into the cathode chamber 2 through the feeding port 6, hydrogen gas is passed into the cathode through the pipeline 11, the electrolysis temperature is 50...

Embodiment 3

[0034] Such as figure 1 Shown, a kind of device of electrolytically preparing lithium borohydride comprises the alumina ceramic electrolytic cell 1 that cathode chamber 2 and anode chamber 3 constitute, wherein cathode chamber 2 and anode chamber 3 are separated by porous magnesia ceramic sheet 12; The upper part of the cathode chamber 2 is provided with a hydrogen outlet 5 and a LiBO 2 and LiAlO 2 The feeding port 6, the side of the cathode chamber is provided with a hydrogen inlet 4, the top of the anode chamber is provided with an oxygen outlet 7; the graphite cathode 8 and the graphite anode 9 are respectively located in the cathode chamber 2 and the inside of the anode chamber 3. 2 and anode compartment 3 with Li 7 B 3 o 8 and LiAlF 4 , AlF 3 and CaF 2 , LiBO 2 and LiAlO 2 The solution is fed into the cathode chamber 2 through the feeding port 6, and the hydrogen gas is passed into the cathode through the pipeline 11. The electrolysis temperature is 600°C, the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com