Process for production of carotenoid

A technology of carotene and its manufacturing method, applied in skin care preparations, chemical instruments and methods, medical preparations containing active ingredients, etc., capable of solving problems such as low simplicity, inefficiency, and solvent residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

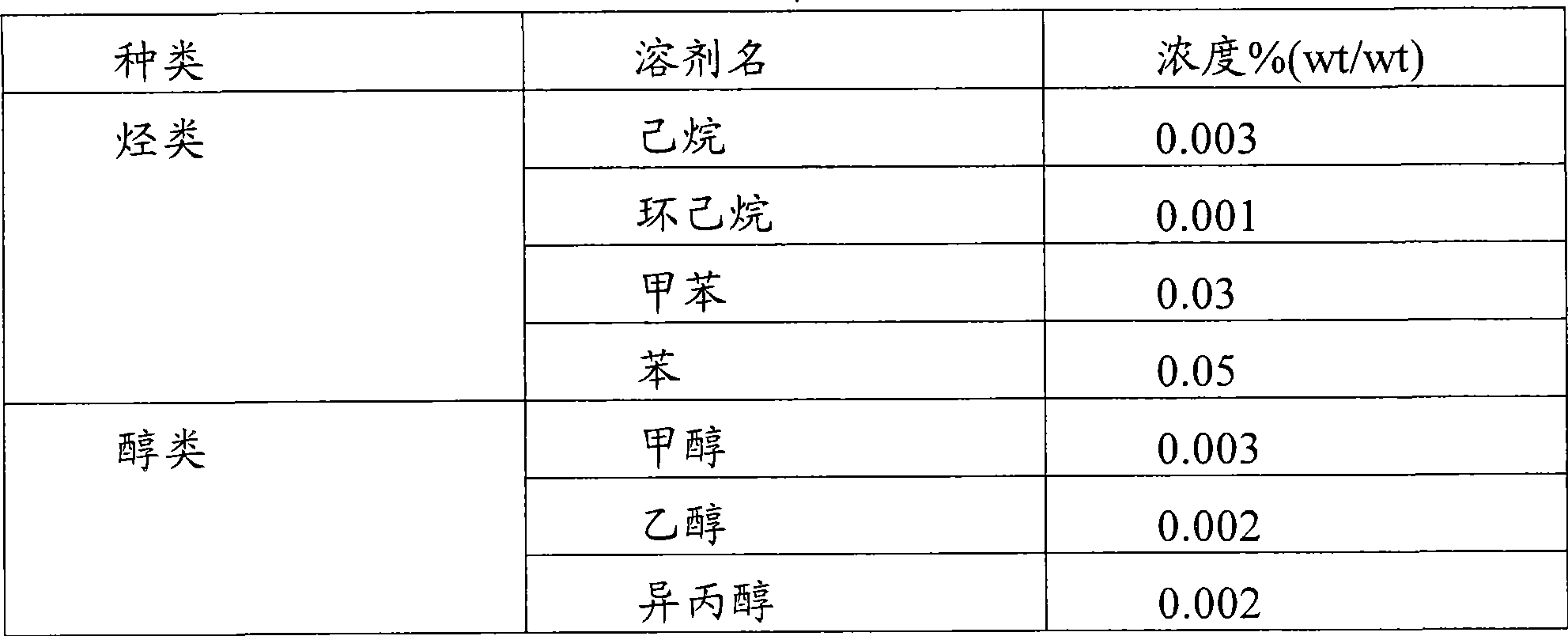

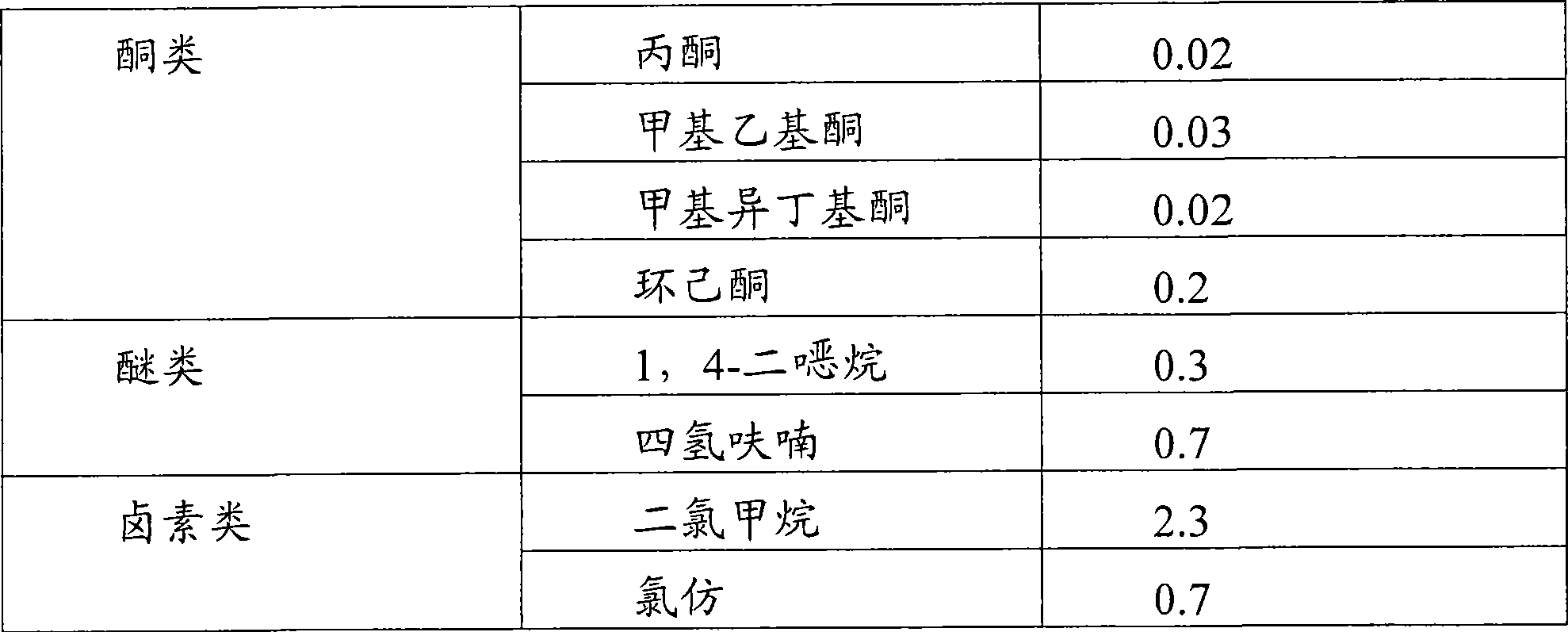

Method used

Image

Examples

Embodiment 1

[0130] [Example 1] Production of high-purity carotenoids with high astaxanthin content 1

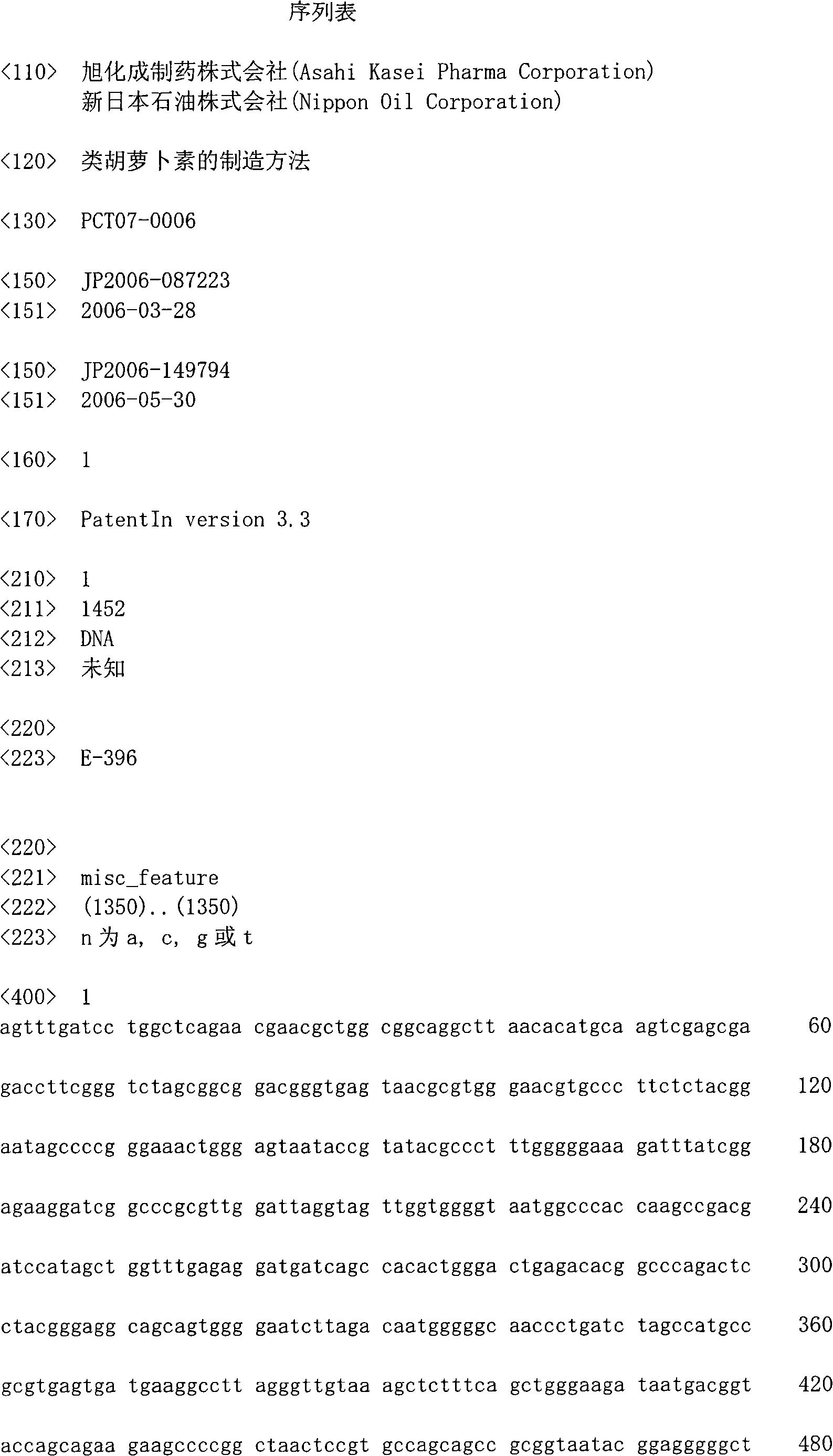

[0131] Step 1: Cultivation steps of E-396 strain

[0132] Add 10 ml of medium containing 2 g / L glucose, 3 g / L meat extract, 10 g / L peptone, and 5 g / L sodium chloride into a test tube with a diameter of 18 mm, and steam sterilize at 121° C. for 15 minutes. One platinum inoculation loop amount of E-396 strain (FERM BP-4283) was inoculated therein, and cultured with repeated shaking at 30° C. and 300 rpm for 6 days. 200 tubes (2 L) of the culture solution were centrifuged and then freeze-dried to obtain dried bacterial cells containing 16 mg of astaxanthin per 1 g.

[0133] Step 2: Ethanol extraction step

[0134] 18 kg of ethanol was added to 62 g of the dried cells obtained in Step 1 of this example, stirred at 50° C. for 3 hours, and carotenoids containing astaxanthin were extracted. Then, the thalline was removed by filtration, and the thalline filter cake (ケク) was washed with ethano...

Embodiment 2

[0144] [Example 2] Production of Astaxanthin High-Content High-Purity Carotenoid Using Recovered Solvent 1

[0145] In 31g of the dried thalline obtained in step 1 of embodiment 1, add 9 kg of the distillate (ethanol) obtained in step 3 of embodiment 1, and carry out extraction of carotenoids and filtration of thalline according to the method in step 2 of embodiment 1 to obtain the extract 9kg. After concentrating the extract under reduced pressure according to Step 3 of Example 1, about 40 g of the cooled concentrate was obtained. The precipitate was filtered off from the cooled concentrate as in Example 1, step 4. Then, 10 g of the ethanol recovered in Step 6 of Example 1 was added from above the precipitate filter cake for filtration and washing, and then dried to obtain 0.75 g of dried product. Add water-containing 25% ethanol (by the ethanol 37.5g that embodiment 1 step 6 reclaims and water 12.5g mix and make) in this dry thing, obtain water-containing 25% ethanol washi...

Embodiment 3

[0147] [Example 3] Production of high-purity carotenoids with high astaxanthin content 2

[0148]Bacterial culture, extraction, concentration and precipitation steps are carried out according to the same method as step 1 to step 3 of embodiment 1, and further according to step 4 of embodiment 1, the cooling concentrate obtained in step 3 is filtered under reduced pressure about 80g to obtain carotenoid-containing sediment filter cake. Further, 20 g of ethanol was added from above the filter cake to filter and wash, and then, a part of the dry filter cake was taken to investigate the carotenoid content of the precipitate. Then, the drying step was omitted, and 100 g of ethanol containing 25% water was added from above the filter cake for further filtration and washing. The filtered and washed cake was dried overnight at 35°C under reduced pressure to obtain 1.5 g of a dried product containing water and 25% ethanol. In the vacuum-dried product before washing with 25% ethanol c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com