Vitamin C microcapsule formulation and preparation method thereof

A vitamin and preparation technology, applied in microcapsules, capsule delivery, pharmaceutical formulations, etc., can solve the problems of difficult control of the reaction process, unstable vitamin C, and unstable feed processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

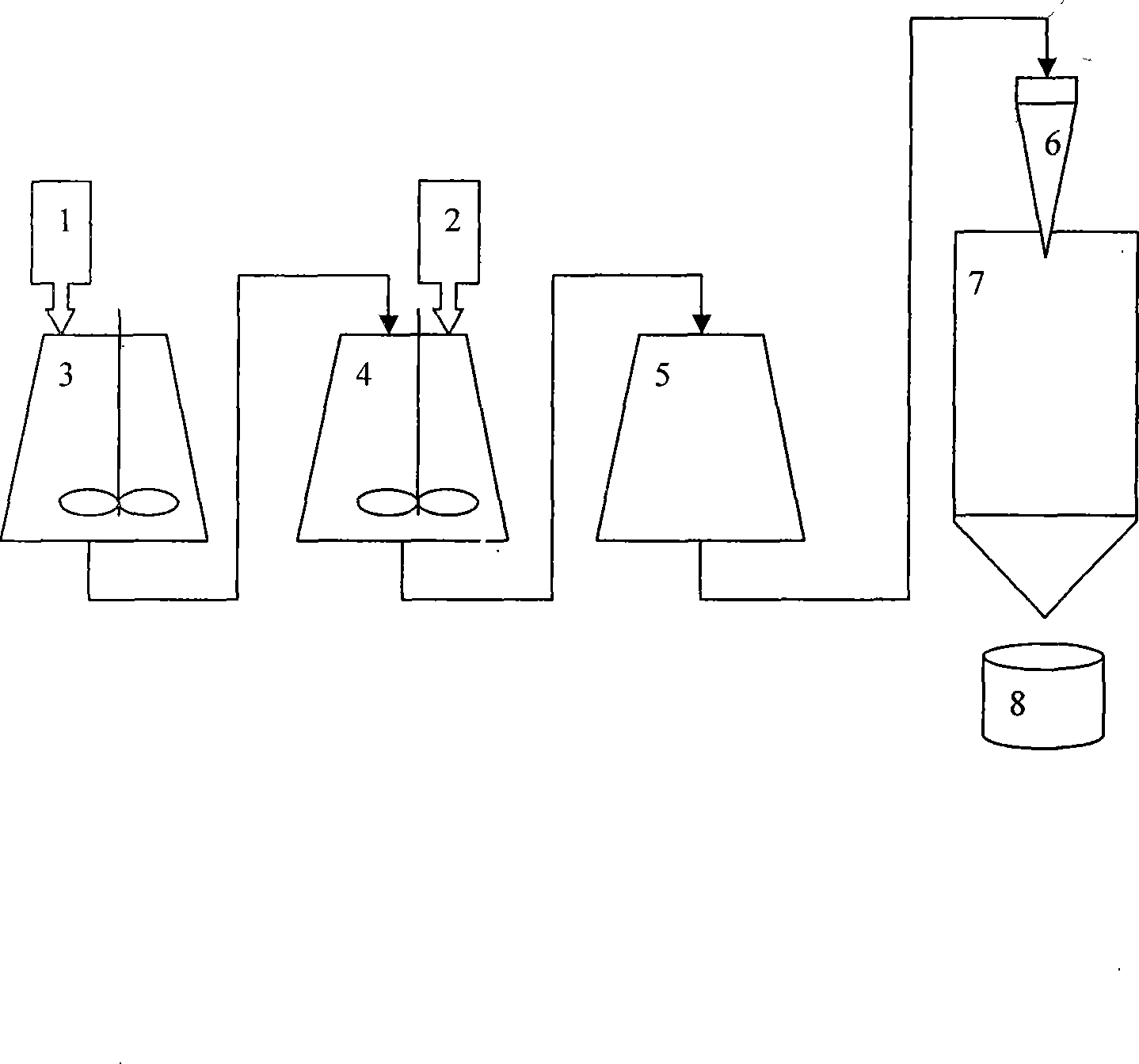

Method used

Image

Examples

example 1

[0040] Select 225kg of stearic acid and put it into the chemical tank, heat it to 80°C, and keep stirring until all the auxiliary materials are melted; pump the melted stearic acid from the chemical tank into the batching tank, and at the same time put 100kg of vitamin C that has been accurately weighed into the batching tank , shear and stir for 10 minutes, during which the temperature should be controlled at 80°C; import the prepared materials into the storage tank, and heat the temperature to 80°C-100°C; start the feeding spray device, and put the prepared materials in the storage tank Granulation by spraying; the granules of the finished product are collected by sieving with a 24-80 mesh vibrating sieve. Finally, 313 kg of finished vitamin C microcapsule preparations were obtained, the particle size was 200 μm-700 μm, and the yield could reach 96%.

example 2

[0042] Select 175kg of paraffin wax and stearic acid (1:1) into the chemical material tank, heat to 80°C, and keep stirring until all the auxiliary materials are melted; pump the melted auxiliary materials from the chemical material tank into the batching tank, and at the same time accurately weigh Put 80kg of vitamin C into the batching tank, shear and stir for 8 minutes, during which the temperature should be controlled at 80°C; import the prepared material into the storage tank, and heat the temperature to 80°C-100°C; start the feeding spray device, and put the stored material The materials in the tank are granulated through spray freezing equipment; the finished product granules are collected by sieving with a 24-mesh-80-mesh vibrating sieve. Finally, 245 kg of finished vitamin C controlled-release microcapsule preparations are obtained, the particle size is 200 μm-700 μm, and the yield can reach 96%.

example 3

[0044] Select calcium stearate monoglyceride and fat powder 220kg (2:1) into the chemical material tank, heat to 80°C, stir continuously, until all the auxiliary materials are melted; pump the melted auxiliary materials from the chemical material tank into the batching tank, and at the same time Put 100kg of vitamin C that has been accurately weighed into the batching tank, shear and stir for 8 minutes, during which the temperature should be controlled at 80°C; import the prepared materials into the storage tank, and heat the temperature to 80°C-100°C; start feeding Spray device, granulate the materials in the storage tank through spray freezing equipment; sieve and collect the finished product granules with a 24-80 mesh vibrating sieve. Finally, 303.5kg of finished vitamin C microcapsule preparation (50%) was obtained, the particle size was 200 μm-700 μm, and the yield could reach 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com