Epoxy organosilicon phosphoester compound modified acrylic resin

A technology of organosilicon phosphate ester and acrylic resin, which is applied in coatings, anti-corrosion coatings, metal material coating processes, etc., can solve the problems of affecting solubility, affecting corrosion resistance, and decreasing adhesion, so as to improve cross-linking density, The effect of excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

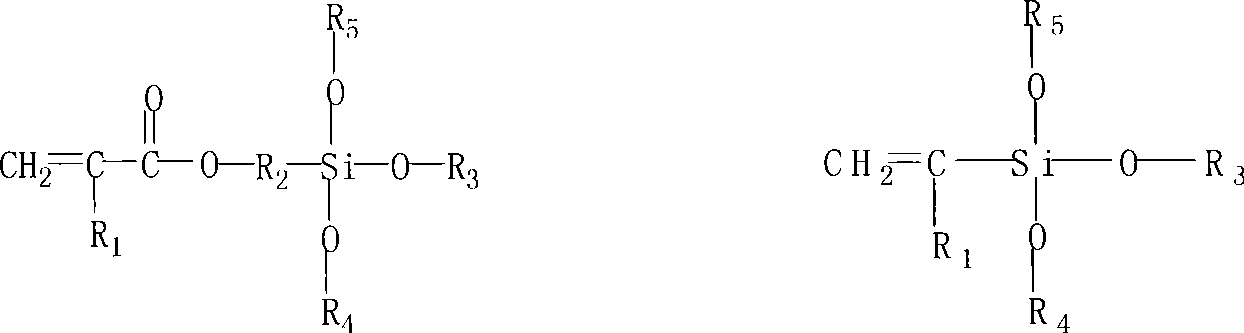

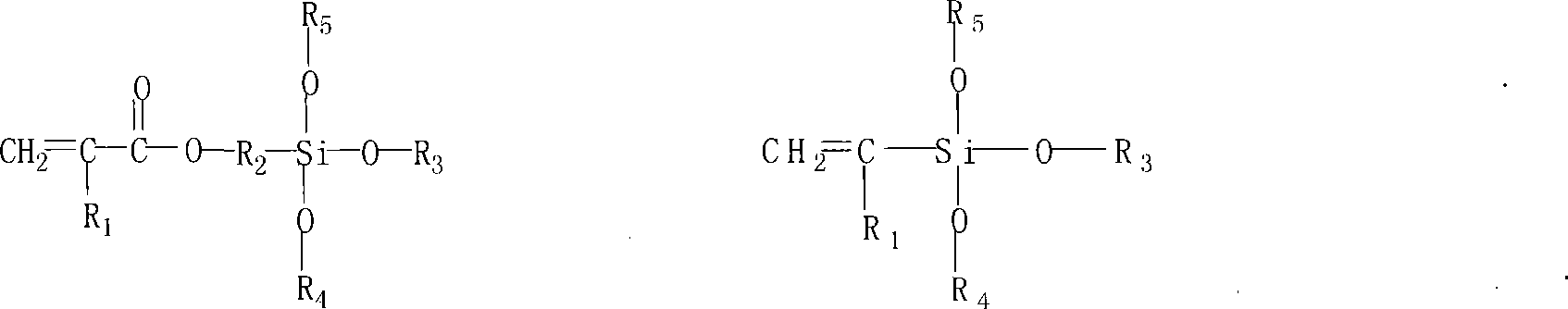

Image

Examples

Embodiment 1~6

[0023] Embodiment 1~6 prepares epoxy organosilicon phosphate composite modified acrylic resin

[0024] (1) See Table 1 for the amount of raw materials, where the amounts are parts by weight

[0025] Table 1

[0026] components

raw material name

Dosage

Example

1 Dosage

Example

2 Dosage

Example

3 Dosage

Example

4 Dosage

Example

5 Dosage

Example

6 Acrylic Mono

body

methyl ester

ester

acrylic acid 30

15

10

5 40

25

12

3 49

30

15

2 30

20

10

5 35

25

12

3 49

30

15

2 epoxy resin

E12

E44 20

/ 10

/ 2

/ /

20 /

10 /

KH-570

DL-151 10

/ 5

/ 1

/ /

10 /

5 /

1

[0027] Phosphate monomer PM-100 10 5 1 5 10 1 Initiator

B...

Embodiment 7

[0044] Embodiment 7 prepares one-component anticorrosion coating

[0045] 100 parts by weight of resin A prepared in Example 1, 17.6 parts by weight of iron red, 6.5 parts by weight of zinc yellow, 6.0 parts by weight of zinc phosphate, 29.1 parts by weight of calcined kaolin, 0.8 parts by weight of bentonite, and 0.6 parts by weight of dispersant BYK-163 After mixing with 40 parts by weight of xylene solvent, grind it to a fineness of less than 50 microns with a sand mill to obtain a single-component anti-corrosion coating, numbered as coating A.

Embodiment 8

[0046] Embodiment 8 prepares one-component anticorrosion coating

[0047] A single-component anti-corrosion coating was prepared basically the same as in Example 7, and the number was coating B, the difference being that the resin used was the resin B prepared in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com