Quantitative analysis method of vanadium in high chrome alloy

A high-chromium alloy, quantitative analysis technology, applied in the field of analytical chemistry, can solve problems such as operational hazards, interference with vanadium determination, corrosion of corundum crucibles, etc., and achieve the effects of expanding the scope of application, simple operation, and easy mastery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

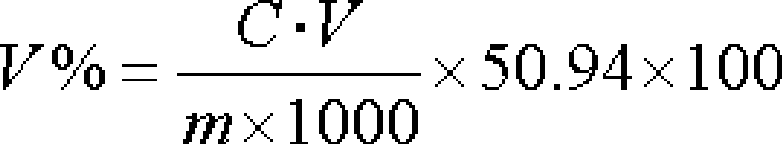

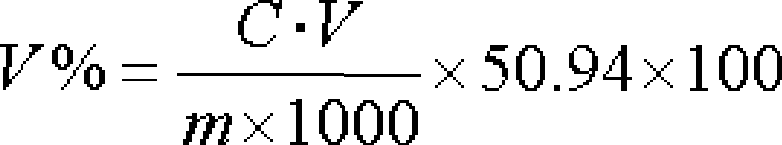

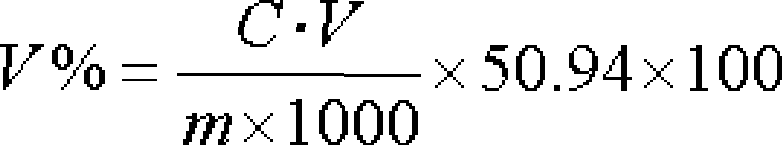

[0027] The mensuration of vanadium (V%) in the hydrogen storage alloy of embodiment 1

[0028] Preparation of mixed acid: sulfuric acid: nitric acid: hydrochloric acid: water = 5: 2.5: 5: 12.5

[0029] Mix 100 mL of sulfuric acid (1+1), 50 mL of nitric acid (1+1), and 100 mL of hydrochloric acid (1+1).

[0030] Three hydrogen storage alloy samples: 1#, 2#, and 3# samples have chromium contents of 21.22%, 21.98%, and 12.95%, respectively.

[0031] Take 0.1000g of 1#, 2#, and 3# samples respectively. Use 25ml of the prepared mixed acid solution to dissolve the high vanadium chromium alloy. Then use 10mL ferrous ammonium sulfate solution with a concentration of 100g / L to reduce and place for 5min, then add potassium permanganate solution with a concentration of 20g / L to oxidize for 3-5min, until the solution turns red and then add 2 drops; add urea, and use sodium nitrite For reduction, add 10ml of ethanol masking agent and let it stand for 1 to 2 minutes, add 3 drops of 2g / L ...

Embodiment 2

[0038] Embodiment 2: the analysis of vanadium content in the iron vanadium standard sample, investigate the interference of chromium to vanadium determination

[0039] A sample similar to the hydrogen storage alloy was prepared by adding the corresponding chromium standard solution to the iron-vanadium standard sample, and analyzed in the manner of Example 1, and carried out a control test with and without adding ethanol. The results are shown in Table 2.

[0040] Analysis results of vanadium (V%) in the standard sample of vanadium iron in table 2:

[0041]

[0042] It can be seen from Table 2 that chromium interferes with the determination of vanadium to a certain extent. After adding ethanol, the measurement results are in good agreement with the standard value, indicating that the interference can be eliminated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com