High specific surface area tungsten carbide microspheres and load type catalyst and their preparation methods

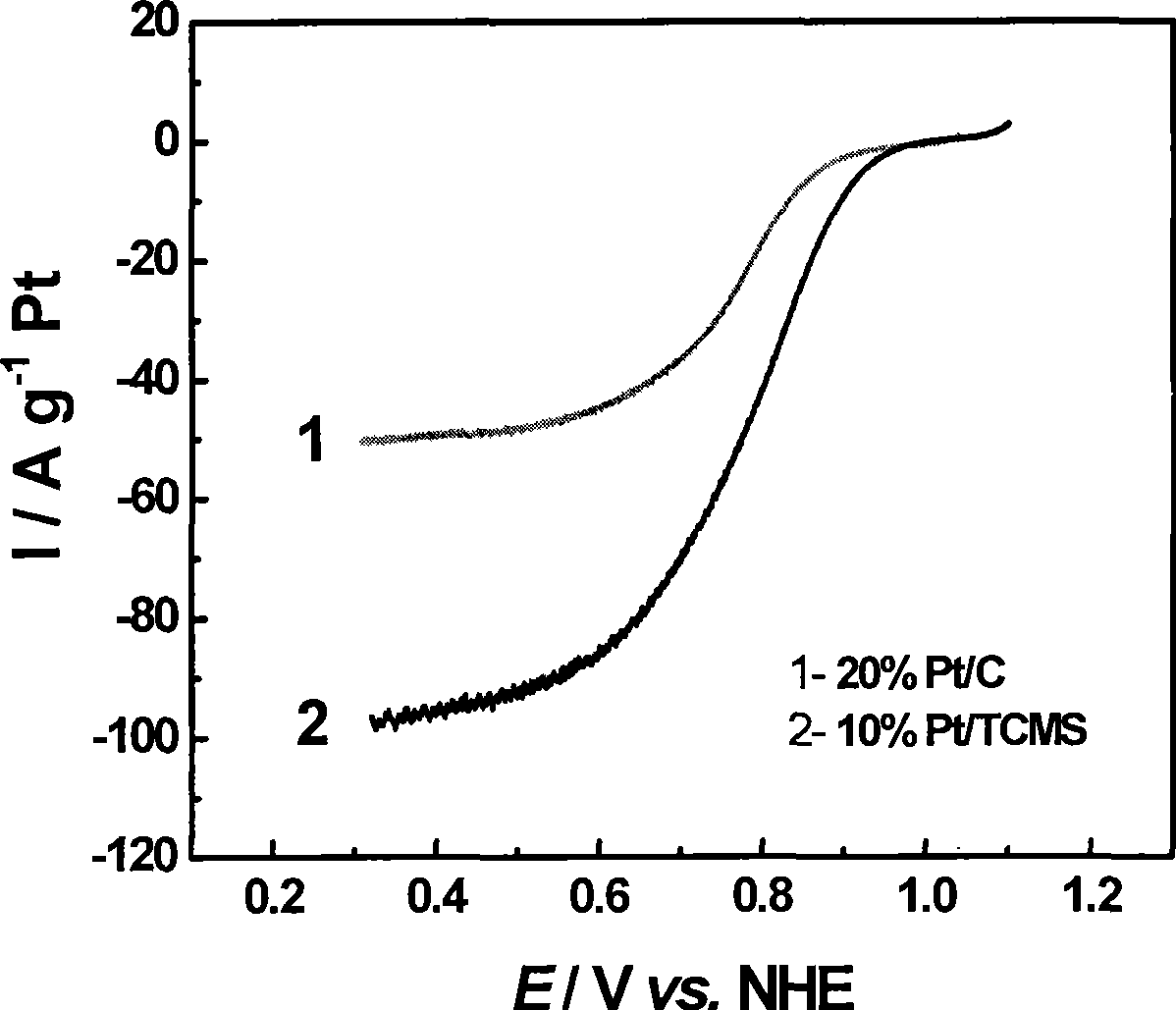

A supported catalyst and tungsten carbide microsphere technology, applied in the field of material science, can solve the problem of not fully meeting the requirements of catalytic materials, and achieve the effects of aerobic reduction catalytic activity, cost reduction, and uniform particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 3.0g of glucose in 40ml of water, add 0.85g of ammonium metatungstate under strong stirring, continue stirring and mixing evenly, then transfer to a 50ml hydrothermal reaction kettle. Keep the temperature at 180° C. for 48 hours in a temperature-programmed oven, and cool to room temperature naturally. Filter, wash with water and alcohol, and dry under vacuum at 80°C to obtain a tan tungsten carbide precursor.

[0031] Take 2.0g tungsten carbide precursor in a boat, place it in a high-temperature tube furnace, under the protection of nitrogen, heat up to 1000°C at 5°C / min, and then feed a mixture of nitrogen and hydrogen (V N2 / V H2 =3:1, v=50ml / min) for 5 hours, cooled to obtain tungsten carbide microspheres.

Embodiment 2

[0033] Dissolve 2.0 g and 0.9 g of sucrose and ammonium metatungstate in 20 ml of water respectively, mix the two solutions evenly under stirring, and transfer them into a 50 ml hydrothermal reaction kettle. Keep the temperature at 150° C. for 10 hours in a temperature-programmed oven, and cool to room temperature naturally. Filter, wash with water and alcohol, and dry under vacuum at 80°C to obtain a tan tungsten carbide precursor.

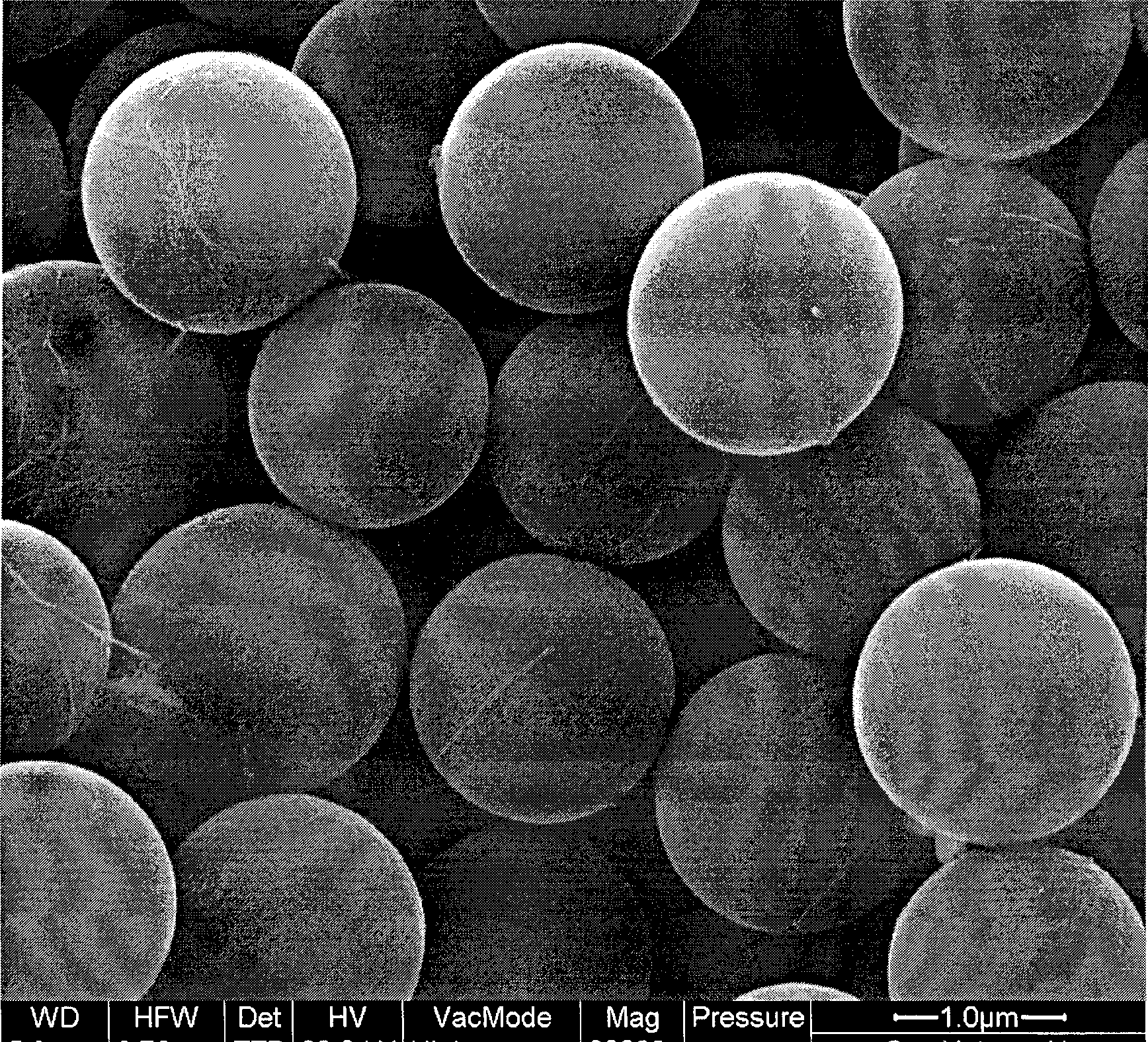

[0034]Take 1.0 g of tungsten carbide precursor in a boat, place it in a high-temperature tube furnace, under the protection of nitrogen, heat up to 1100 °C at 3 °C / min, and then feed a mixture of nitrogen and hydrogen (V N2 / V H2 =2:1, v=30ml / min) for 10 hours, cooled to obtain tungsten carbide microspheres. attached figure 1 The scanning electron microscope image of tungsten carbide microspheres prepared by this method shows that the product is a regular spherical shape with a particle size of about 1 μm and uniform distribution.

Embodiment 3

[0036] Dissolve 3.0 grams of glucose in 40ml of water, add 0.45g of pertungstic acid solution under strong stirring, continue to stir and mix evenly, then transfer to a 50ml hydrothermal reaction kettle. Keep the temperature at 180° C. for 48 hours in a temperature-programmed oven, and cool to room temperature naturally. Filter, wash with water and alcohol, and dry under vacuum at 80°C to obtain a tan tungsten carbide precursor.

[0037] Take 2.5g tungsten carbide precursor in a boat, place it in a high-temperature tube furnace, under the protection of nitrogen, heat up to 1400°C at 5°C / min, then feed a mixture of nitrogen and acetylene (V N2 / V C2H2 =4:1, v=50ml / min) for 8 hours, cooled to obtain tungsten carbide microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com