Wet method accurate sizing technique for preparing superfine function powder

A technology of functional powder and wet method, applied in the direction of wet separation, solid separation, chemical instruments and methods, etc., can solve the problems of low degree of refinement, difficult industrial application, low purity, etc., to increase functionality and phase Capacitance, excellent industrial value, excellent surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

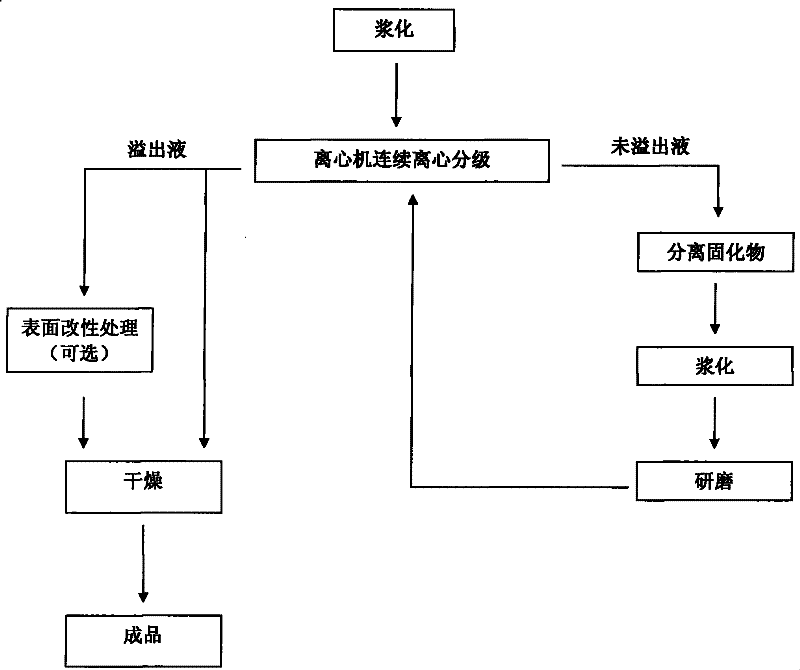

[0017] Such as figure 1 As shown, a wet precise classification process for the preparation of ultrafine functional powders comprises the following steps: firstly, the prepared initial barium sulfate powder material is slurried, and the obtained barium sulfate powder suspension is The mass percentage of solid matter in the medium is controlled at 20%, the barium sulfate powder suspension after slurrying is transported in the continuous centrifuge, the frequency of adjusting the continuous centrifuge is 35Hz, the differential speed ratio is controlled at 25r, the separation factor is 2200, and the centrifuge The suspension overflowed during the process is separated and dried (dried by hot air) and stored as a finished product; the solidified product separated from the suspension that does not overflow during continuous centrifugation is slurried and ground before entering the continuous centrifuge for centrifugation. All initial barium sulfate powders are classified by wet metho...

Embodiment 2

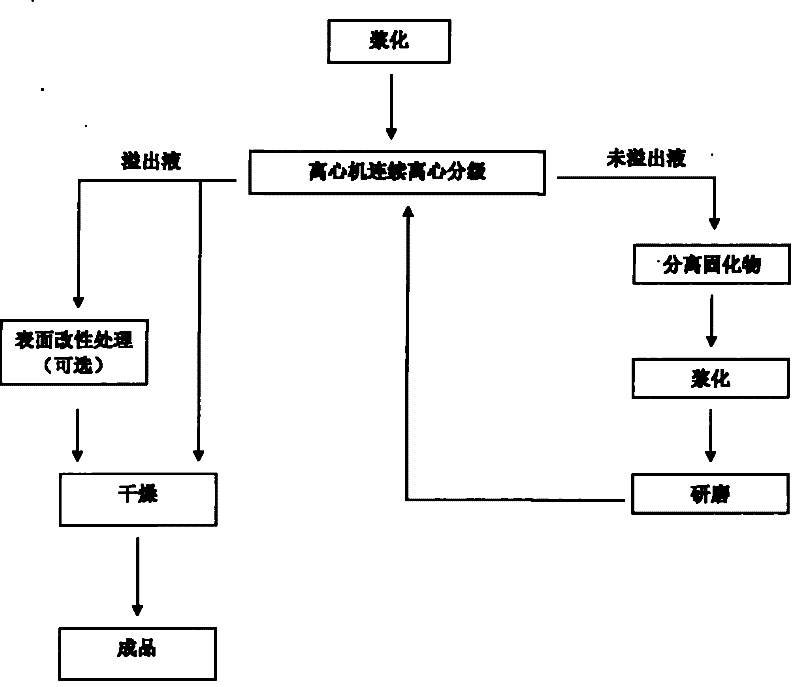

[0019] A wet method precise classification process for the preparation of ultrafine functional powders, comprising the following steps: firstly, the prepared initial barium sulfate powder material is slurried, and the solid content in the barium sulfate powder suspension obtained after the slurry is The mass percentage is controlled at 10%, the barium sulfate powder suspension after slurrying is transported in the continuous centrifuge, the frequency of adjusting the continuous centrifuge is 45Hz, the differential speed ratio is controlled at 25r, and the separation factor is 2900, overflowing during centrifugation The suspension is separated and dried (using hot air) to store the finished product; the solidified product separated from the suspension that does not overflow during continuous centrifugation is slurried and ground before entering the continuous centrifuge for centrifugation. All initial barium sulfate powders are classified by wet method and dried to obtain barium...

Embodiment 3

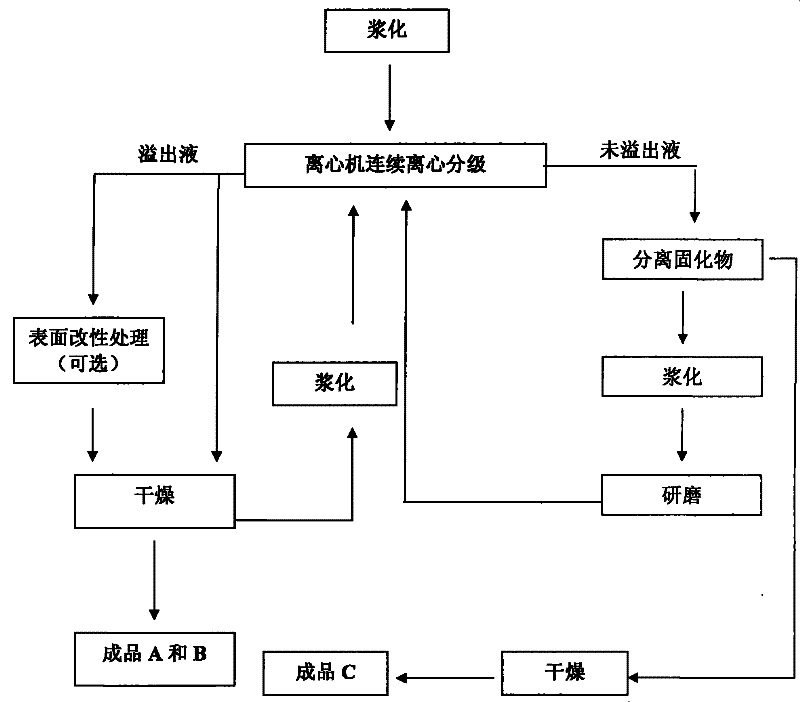

[0021] Such as figure 2 As shown, a wet precise classification process for the preparation of ultrafine functional powders comprises the following steps: firstly, the prepared initial barium sulfate powder material is slurried, and the obtained barium sulfate powder suspension is The mass percentage of solid matter in the medium is controlled at 20%, the barium sulfate powder suspension after slurrying is transported in the continuous centrifuge, the frequency of adjusting the continuous centrifuge is 35Hz, the differential speed ratio is controlled at 25r, the separation factor is 2200, and the centrifuge The suspension overflowed during the process is separated and dried (dried by hot air) to obtain the finished product A for storage; the solidified product separated from the suspension that does not overflow during continuous centrifugation is slurried and ground before entering the continuous centrifuge for centrifugation . All initial barium sulfate powders are classifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com