TaC-SiC ceramic composite material synthesized by hot pressing at in-situ reaction and synthetic method thereof

A ceramic composite material and in-situ reaction technology, which is applied in the field of in-situ reaction hot-pressing synthesis of TaC-SiC ceramic composite materials and its synthesis field, can solve the problems of unsatisfactory anti-oxidation performance of TaC and easy formation of loose surface oxide layer, etc. Achieve excellent high temperature oxidation resistance, improve high temperature oxidation resistance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

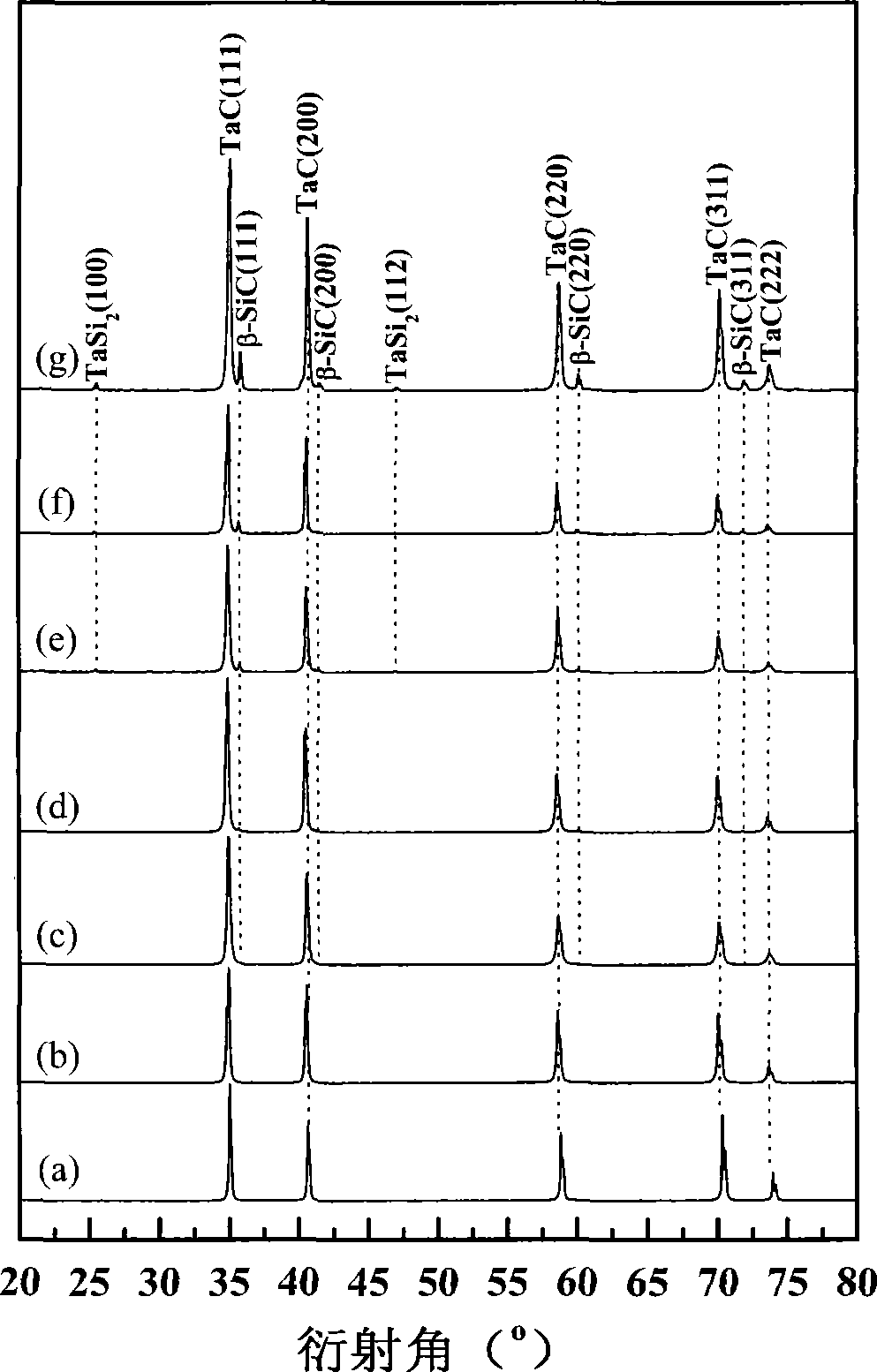

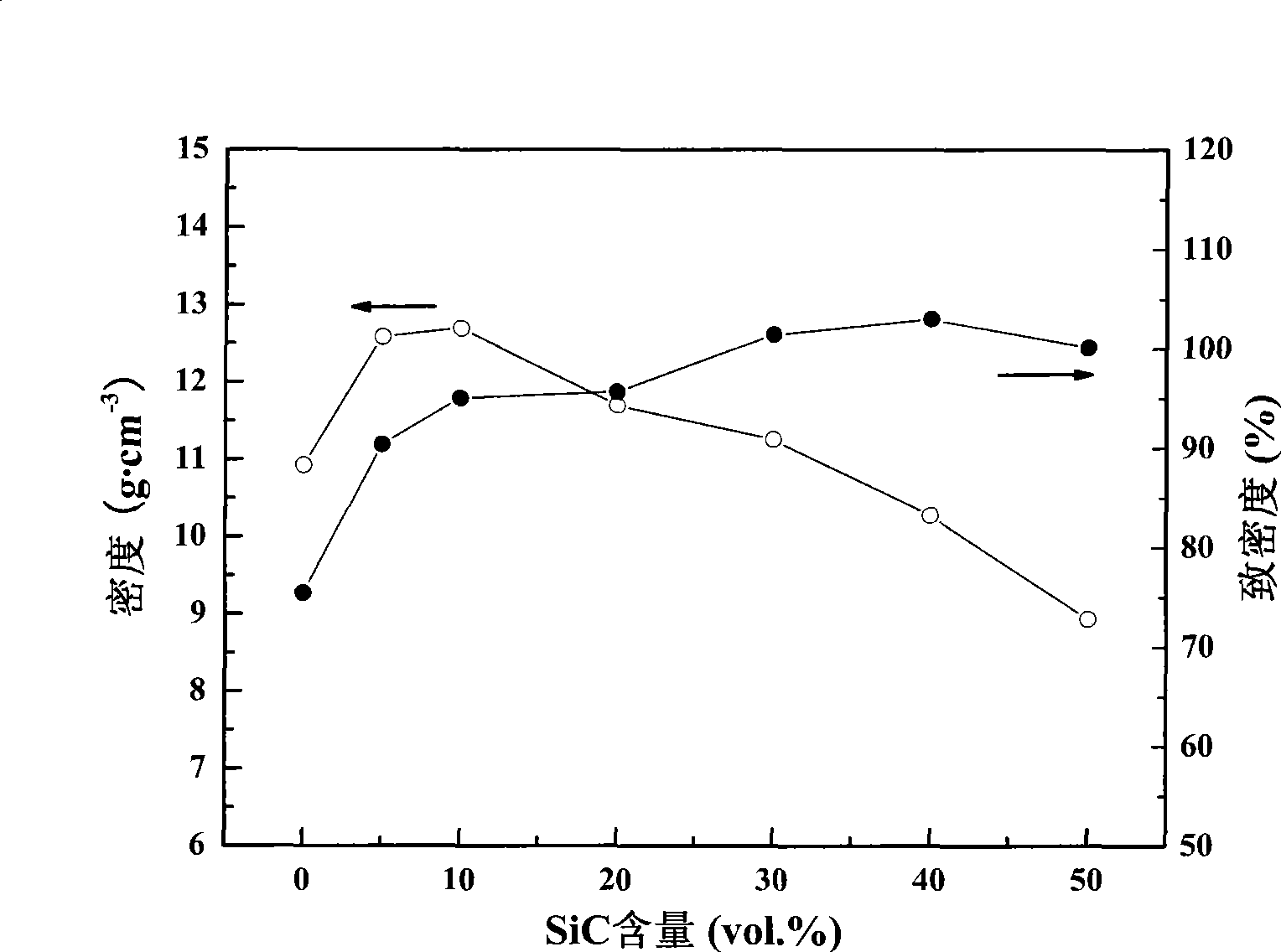

[0020] Embodiment 1 (TaC-5vol.% SiC, TAS5)

[0021] 90.3g of tantalum powder, 0.80g of silicon powder and 5.71g of graphite powder with a particle size ranging from 200 to 600 mesh were ball-milled in a resin tank for 40 hours, passed through a 200-mesh sieve, and then put into a graphite mold for cold press molding. The applied pressure was 10MPa, put it into a hot-press furnace for hot-press sintering. The heating rate is 15°C / min, heated to 1950°C and kept for 2 hours, and the applied pressure is 30MPa. The entire sintering process is carried out under the protection of argon, and the obtained reaction product is analyzed as TaC by X-ray diffraction, and no diffraction peak appears due to the small content of SiC. The density measured by the Archimedes method is 12.58g / cm 3 , which is 90.4% of the theoretical density. The Vickers hardness is 6.3GPa, the bending strength is 309MPa, and the fracture toughness is 2.9MPa m 1 / 2 , the modulus of elasticity is 353GPa.

Embodiment 2

[0022] Example 2 (TaC-10vol.% SiC, TAS10)

[0023] 91.67g of tantalum powder, 1.71g of silicon powder and 6.12g of graphite powder with a particle size ranging from 200 to 600 mesh were ball-milled in a resin tank for 10 hours, passed through a 200-mesh sieve, and then put into a graphite mold for cold press molding. The applied pressure was 20MPa, put it into a hot-press furnace for hot-press sintering. The heating rate is 15°C / min, heated to 2050°C and kept for 1 hour, and the applied pressure is 40MPa. The whole sintering process is carried out under the protection of argon, and the obtained reaction products are analyzed as TaC and β-SiC by X-ray diffraction. The density measured by the Archimedes method is 12.69g / cm 3 , 95.0% of the theoretical density. The Vickers hardness is 8.9GPa, the bending strength is 341MPa, and the fracture toughness is 2.6MPa m 1 / 2 , the modulus of elasticity is 410GPa.

Embodiment 3

[0024] Embodiment 3 (TaC-20vol.% SiC, TAS20)

[0025] 90.55g of tantalum powder, 3.75g of silicon powder and 6.85g of graphite powder with a particle size ranging from 200 to 600 mesh were ball-milled in a resin tank for 20 hours, passed through a 200-mesh sieve, and then put into a graphite mold for cold-press molding. The applied pressure was 5MPa, put it into a hot-press furnace for hot-press sintering. The heating rate is 10°C / min, heated to 1950°C and kept for 1 hour, and the applied pressure is 40MPa. The whole sintering process is carried out under the protection of argon, and the obtained reaction products are analyzed as TaC and β-SiC by X-ray diffraction. The density measured by the Archimedes method is 11.70g / cm 3 , 95.7% of the theoretical density. The Vickers hardness is 8.4GPa, the bending strength is 309MPa, and the fracture toughness is 3.9MPa m 1 / 2 , the modulus of elasticity is 398GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com