Nimesulide sustained-release tablet and preparation method thereof

A technology for sustained-release tablets and matrix sustained-release materials, which is used in pharmaceutical formulations, drug delivery, amide active ingredients, etc., to achieve the effects of reducing surface tension, good process reproducibility, and reducing the number of times of taking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

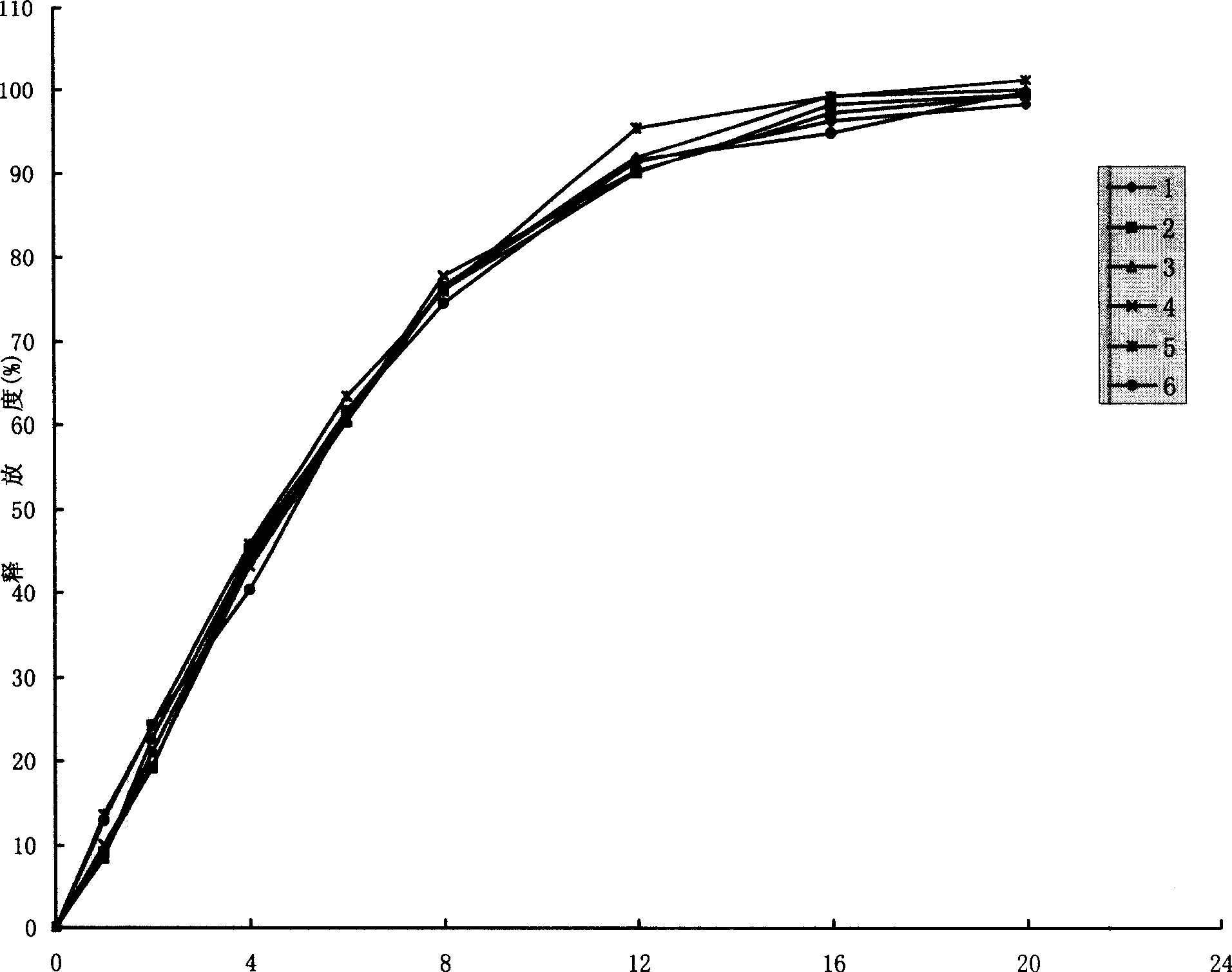

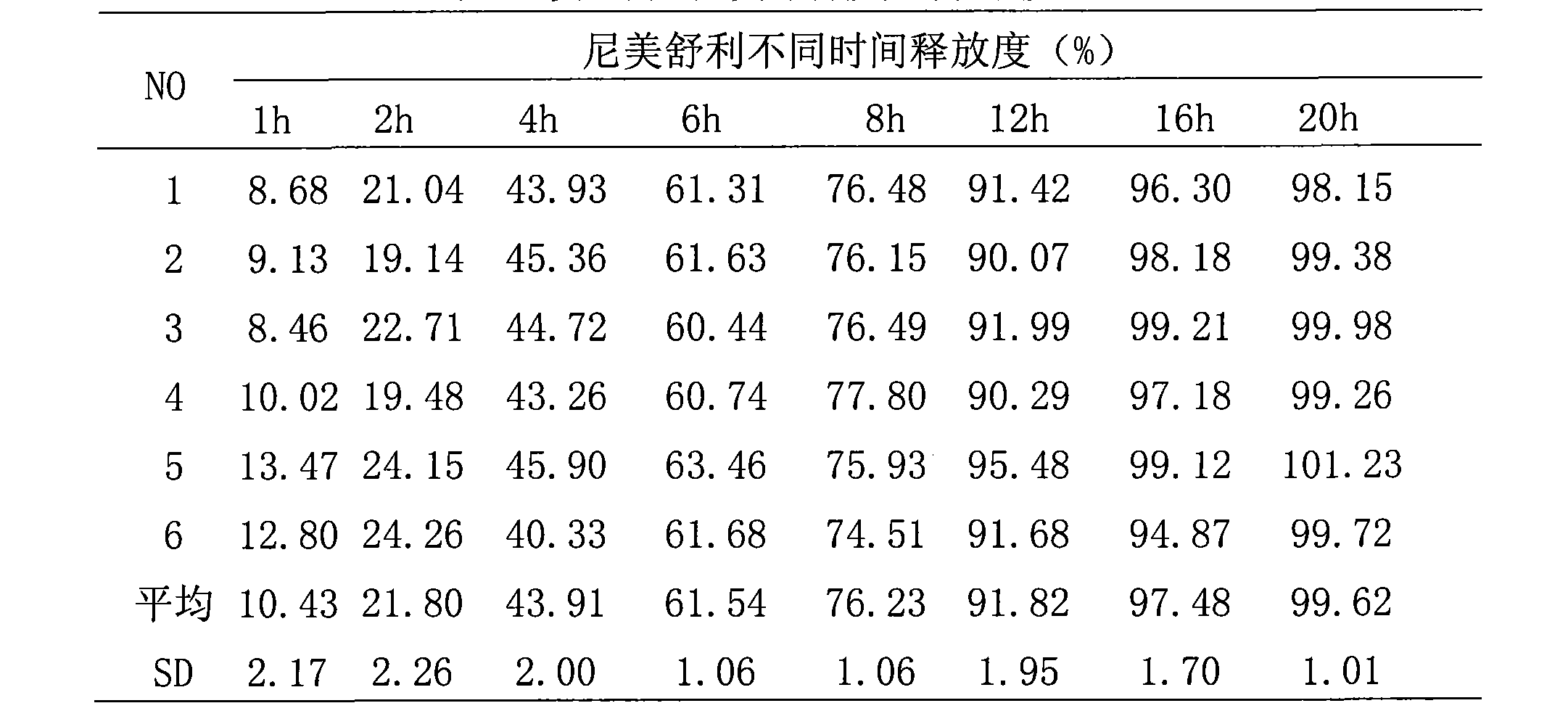

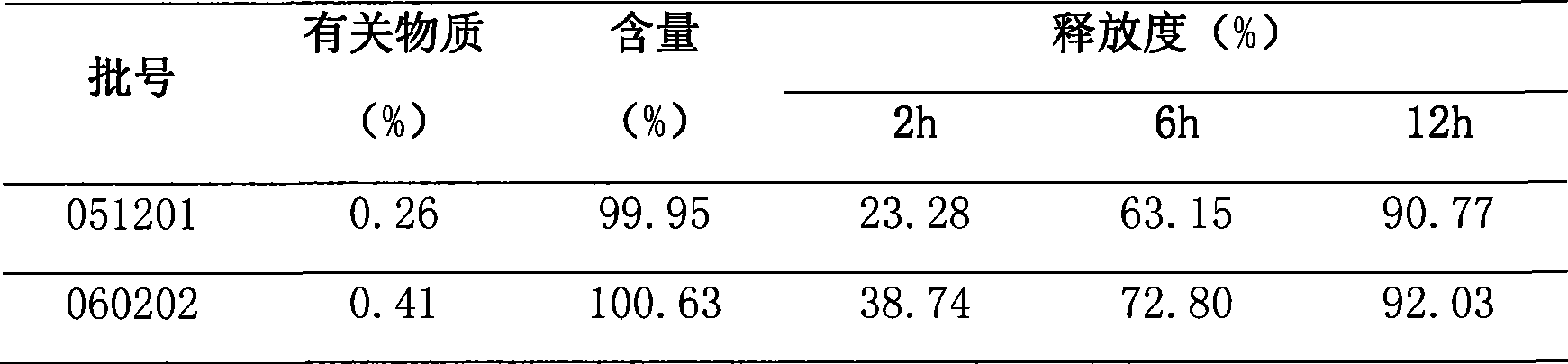

Image

Examples

Embodiment 1

[0021] 1000 Nimesulide Sustained Release Tablets, each containing Nimesulide 200mg.

[0022] Nimesulide 200g,

[0023] Hypromellose 60RT50 100g,

[0024] Compressible starch 100g,

[0026] 2.5% ethyl cellulose 95% ethanol solution 140ml.

[0027] Preparation method: mix nimesulide, hypromellose, compressible starch, etc. uniformly according to the method of equal amount addition, and use 140ml of 2.5% ethylcellulose and 95% ethanol solution to make the powder after mixing uniformly Material, pass through 16 mesh sieve to granulate, ventilate and dry at 55~60℃, control water content <3%, after granulation with 14 mesh sieve, add magnesium stearate in prescribed amount, mix well, compress into tablets, control tablet The hardness is between 6.5 and 7.5kg.

Embodiment 2

[0029] 1000 Nimesulide Sustained Release Tablets, each containing Nimesulide 200mg.

[0030] Nimesulide 200g,

[0031] High viscosity hypromellose 90g,

[0032] Low viscosity hypromellose 10g,

[0033] Compressible starch 100g,

[0035] 2.5% ethyl cellulose 95% ethanol solution 140ml.

[0036] Preparation method: mix high-viscosity hypromellose and low-viscosity hypromellose to form hypromellose with a viscosity of 4000 milliPascal seconds, and add nimesulide and hypromellose to , compressible starch, etc., mix well, use 140ml of 2.5% ethyl cellulose and 95% ethanol solution to make the above mixed powder into a soft material, pass through a 16-mesh sieve to granulate, and ventilate and dry at 55-60°C to control the content of The amount of water is less than 3%. After the granules are sized with a 14-mesh sieve, the prescribed amount of magnesium stearate is added, mixed evenly, and compressed into tablets. The hardness of the tablets is c...

Embodiment 3

[0038]1000 Nimesulide Sustained Release Tablets, each containing Nimesulide 200mg.

[0039] Nimesulide 200g,

[0040] High viscosity hypromellose 65g,

[0041] Low viscosity hypromellose 35g,

[0042] Compressible starch 100g,

[0044] 4.5% polyvinylpyrrolidone 95% ethanol solution 120ml.

[0045] The preparation method is the same as in Example 2, wherein the high viscosity hypromellose and the low viscosity hypromellose are mixed to form the hypromellose with a viscosity range of 2000 milliPascals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com