Circulative reuse treatment method of electric ultrapure water

A technology of recycling and treatment methods, which is applied in the field of water treatment, can solve the problems of limited and unreachable effects of degradation and removal, and achieve the effects of reducing construction costs, obvious effects, and system safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

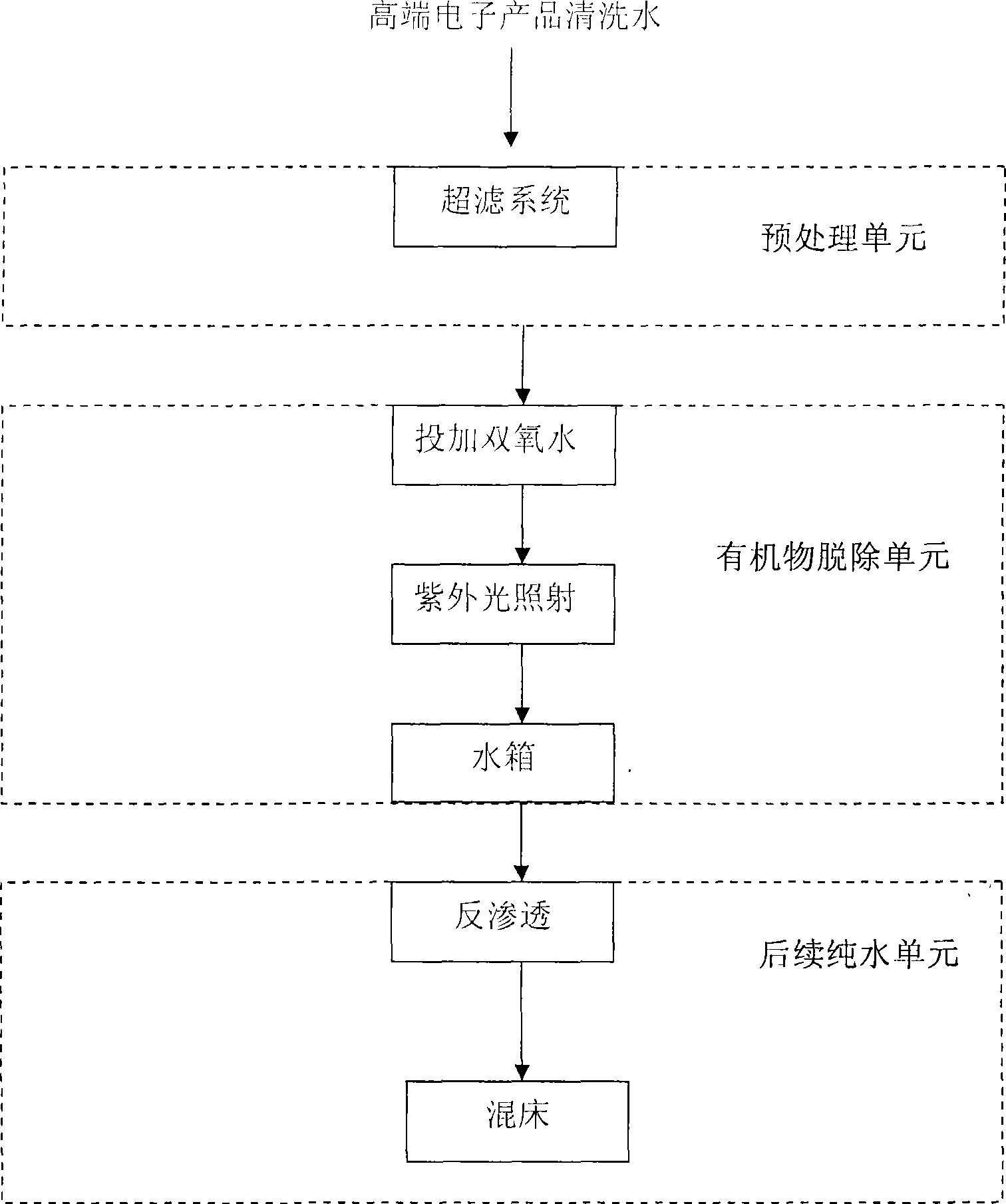

[0028] The method step of the present invention can be divided into three major units, the first unit is a pretreatment unit, that is, the ultrafiltration system treatment; the second unit is an organic matter removal unit, which includes: hydrogen peroxide oxidative decomposition treatment, ultraviolet irradiation and water tank placement Decomposition; the third unit is the follow-up pure water unit, which includes two steps: membrane treatment and mixed bed treatment. After the five-step process of the above three units, the cleaning water of electronic high-end electronic products can be treated into pure water that can be recycled for cleaning electronic products.

[0029] In this embodiment, firstly, the cleaning water of high-end electronic products to be treated is sampled and tested, and the concentration of hydrophilic polymer cleaning agent contained in it is determined to be 50 ppm, as well as a small amount of suspended impurities and inorganic salts, and the condu...

Embodiment 2

[0040] In the hydrogen peroxide treatment step of the present embodiment, 200ppm hydrogen peroxide is added; in the ultraviolet irradiation treatment step, a low-ozone type low-pressure mercury vapor discharge ultraviolet lamp is used, and the typical ultraviolet radiation efficiency of wavelength 185nm is about 5%, and the typical ultraviolet radiation efficiency of wavelength 254nm The efficiency is about 35%, and the average dose is 500J / m 2 ; And the irradiated product water stays in the water tank for 60 minutes for reaction.

[0041] Other parts of this embodiment are the same as Embodiment 1.

Embodiment 3

[0043]In the hydrogen peroxide treatment step of the present embodiment, 300 ppm of hydrogen peroxide is added; in the ultraviolet irradiation treatment step, a low-ozone low-pressure mercury vapor discharge ultraviolet lamp is used, and the typical ultraviolet radiation efficiency of wavelength 185nm is about 5%, and the typical ultraviolet radiation efficiency of wavelength 254nm The efficiency is about 35%, and the average dose is 250J / m 2 ; And the irradiated product water stays in the water tank for 40 minutes for reaction.

[0044] Other parts of this embodiment are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com