Production process of novel environment friendly biological rubber aromatic oil

A production process and technology for aromatic oil, which is applied in the refining field of reformed aromatic oil, can solve the problems of large dosage, deepened color, non-regeneration of white clay, etc., and achieves the effect of wide source and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

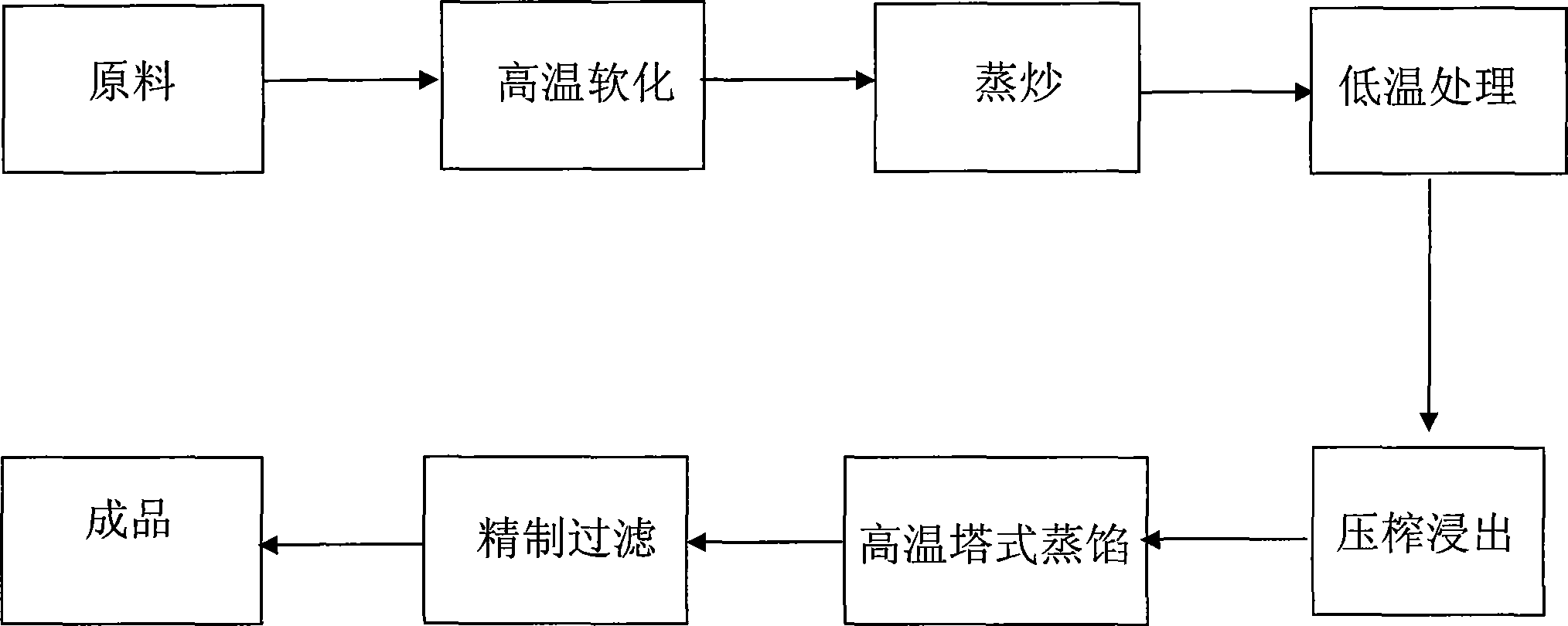

[0012] A new type of production process for environmentally friendly bio-rubber aromatic oil, using oil extracted from Lauraceae, Apocynaceae, Asteraceae, Orchidaceae, Cyperaceae, Romoaceae, and plant edible oils as raw materials to produce aromatic oil. It is characterized in that ① first soften the raw materials at high temperature at a temperature of 80°C-200°C; ②steam and fry them in a steamer for 60 minutes; 4. Squeeze and leach through a press to squeeze out the liquid; 5. Treat the obtained liquid at a high temperature in a tower distillation machine at a temperature of 280°C. 6. Finally, refine and filter in a filter to obtain aromatic oil.

[0013] The vegetable edible oil extracted oil is a mixture of cottonseed oil and rapeseed oil, and its weight ratio is 1.5:1.

[0014] The weight ratio of Lauraceae, Apocynaceae, Asteraceae, Orchidaceae, Cyperaceae and Romoaceae is 1.5:1.5:1.5:1:1:1.

[0015] The ratio of family to vegetable edible oil is 2:1.

[0016] Use any m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com