Conglobation type nanostructured lithium iron phosphate anode material and method for producing the same

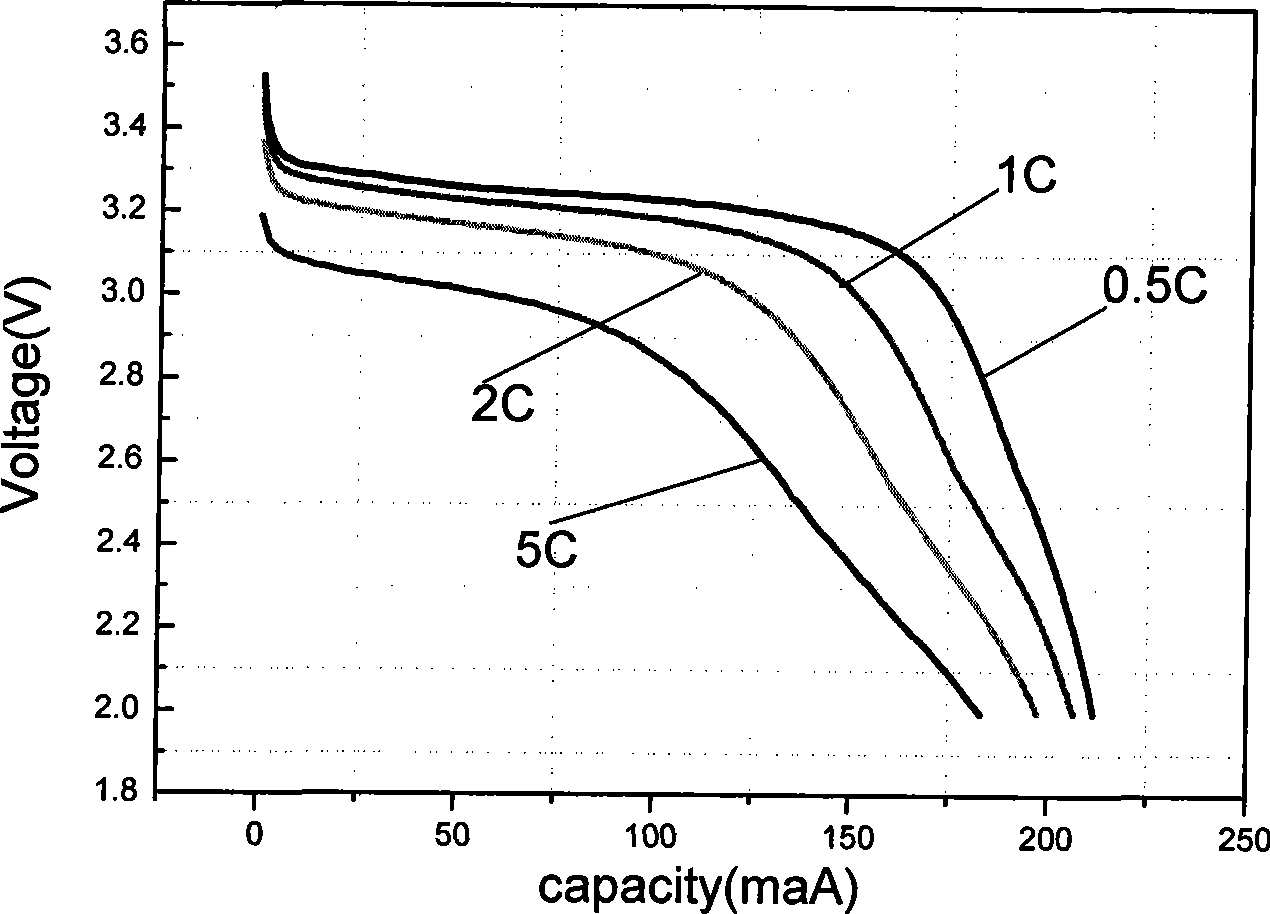

A technology of lithium iron phosphate and nanostructures, which is applied to structural parts, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of low tap density, poor processing performance, and shedding of active substances, and achieve high tap density and processing good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Add 1.0mol FeSO 4 .7H 2 O and 1.0 mol of phosphoric acid were dissolved in distilled water, then the pH of the solution was adjusted to 7 with ammonia water, and stirred at high speed for 3 hours to obtain a light green suspension. Filtration, washing with water and drying to obtain the initial nano-precursor.

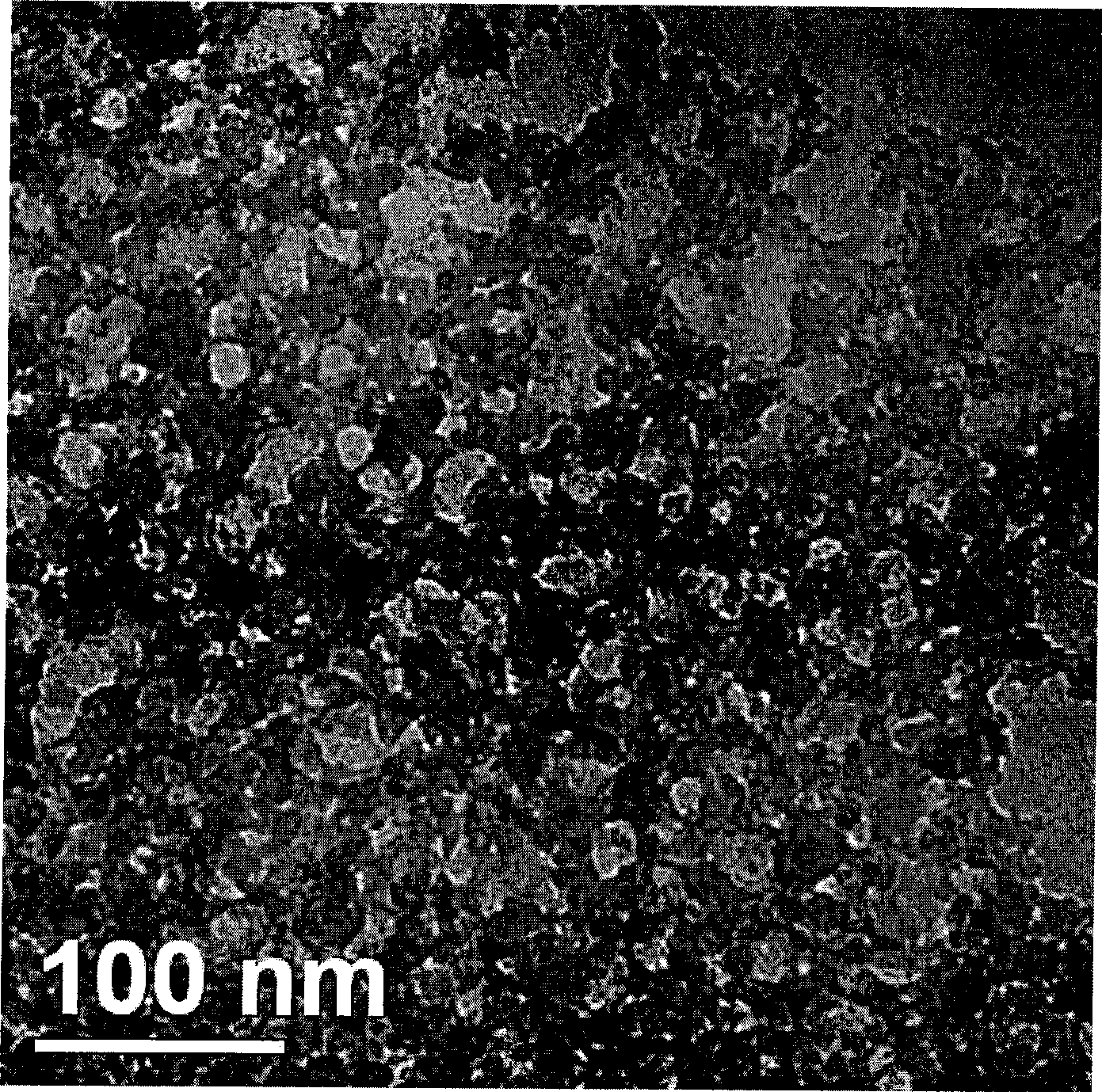

[0054] 2. Ball mill the initial nano-precursor obtained in the above steps with 15.8 g glucose, 1 mol LiOH, 0.2 mol phosphoric acid, and 1.5% CMC in an aqueous solution for 24 hours to react and obtain a colloidal suspension. Then spray the colloidal suspension into the drying tower with a centrifugal atomizing disc. The temperature in the drying tower is controlled at 350±5°C for drying. Agglomerated powder.

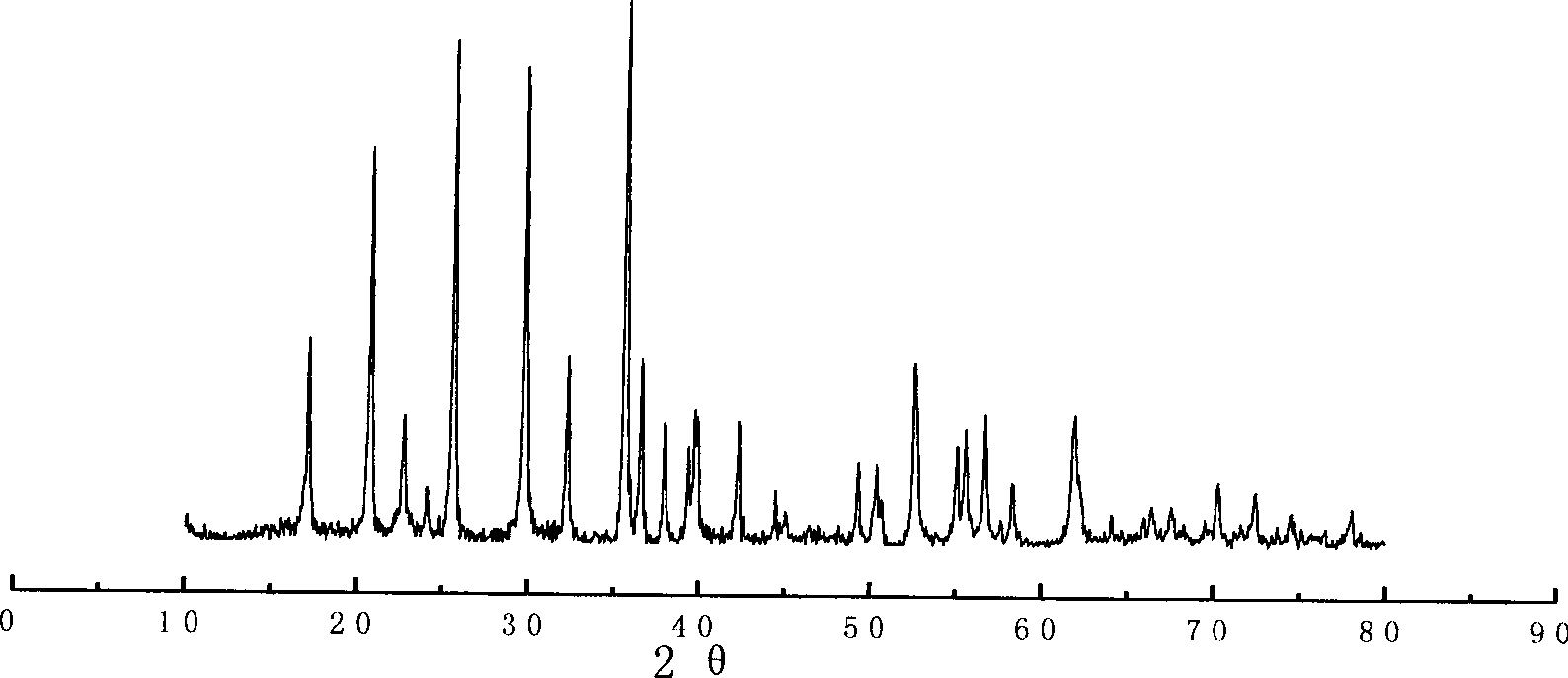

[0055] 3. Roast the agglomerated powder in step 2 at a high temperature of 700°C for 3 hours in a sealed tube furnace protected by nitrogen, then raise the temperature of the furnace to 1000°C and keep it warm for 15 minutes, then quickly pour the s...

Embodiment 2

[0058] 1. Mix 1mol FeSO 4 .7H 2 O and 1 mol of phosphoric acid were dissolved in distilled water, then the pH of the solution was adjusted to 7 with ammonia water, and stirred at high speed for 3 hours to obtain a light green suspension. Filtration, washing with water to obtain nano ferrous phosphate.

[0059] 2. Combine the nano-ferrous phosphate obtained in the above steps with 18g glucose, 0.9molLiOH, 0.2mol phosphoric acid and 0.025molZrO 2 High-speed spherical grinding and dispersing in the aqueous solution system for 5 hours to obtain a colloidal suspension, and then use a two-fluid nozzle to spray the colloidal suspension into the drying tower. The slurry is agglomerated by its own physical changes. Control the temperature at 250±5°C, and control the temperature at the air outlet at 120±5°C. After fully drying, collect the dried agglomerated powder with a cyclone separator.

[0060] 3. Roast the agglomerated powder in step 2 at a high temperature of 700°C for 3 hours...

Embodiment 3

[0063] 1. Mix 1.0molFe(NO 3 ) 3 .9H 2 O and 1.0 mol of phosphoric acid were dissolved in distilled water, then the pH of the solution was adjusted to 7 with ammonia water, and stirred at high speed for 3 hours to obtain a white suspension. Filtrating, washing with water and drying to obtain the nanometer precursor.

[0064] 2. Combine the nano-precursor obtained in the above steps with 25g glucose, 0.9molLiOH, 0.01molNb 2 o 5 High-speed spherical grinding and dispersion in the aqueous solution system for 5 hours to obtain a colloidal suspension, and then use a two-fluid nozzle to spray the colloidal suspension into the drying tower. The slurry is reunited by its own physical changes, and the temperature of the air inlet in the drying tower is controlled. At 250±5°C, the temperature at the air outlet is controlled at 120±5°C. After fully drying, collect the dried agglomerated powder with a cyclone separator.

[0065] 3. Roast the agglomerated powder in step 2 at a high tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com