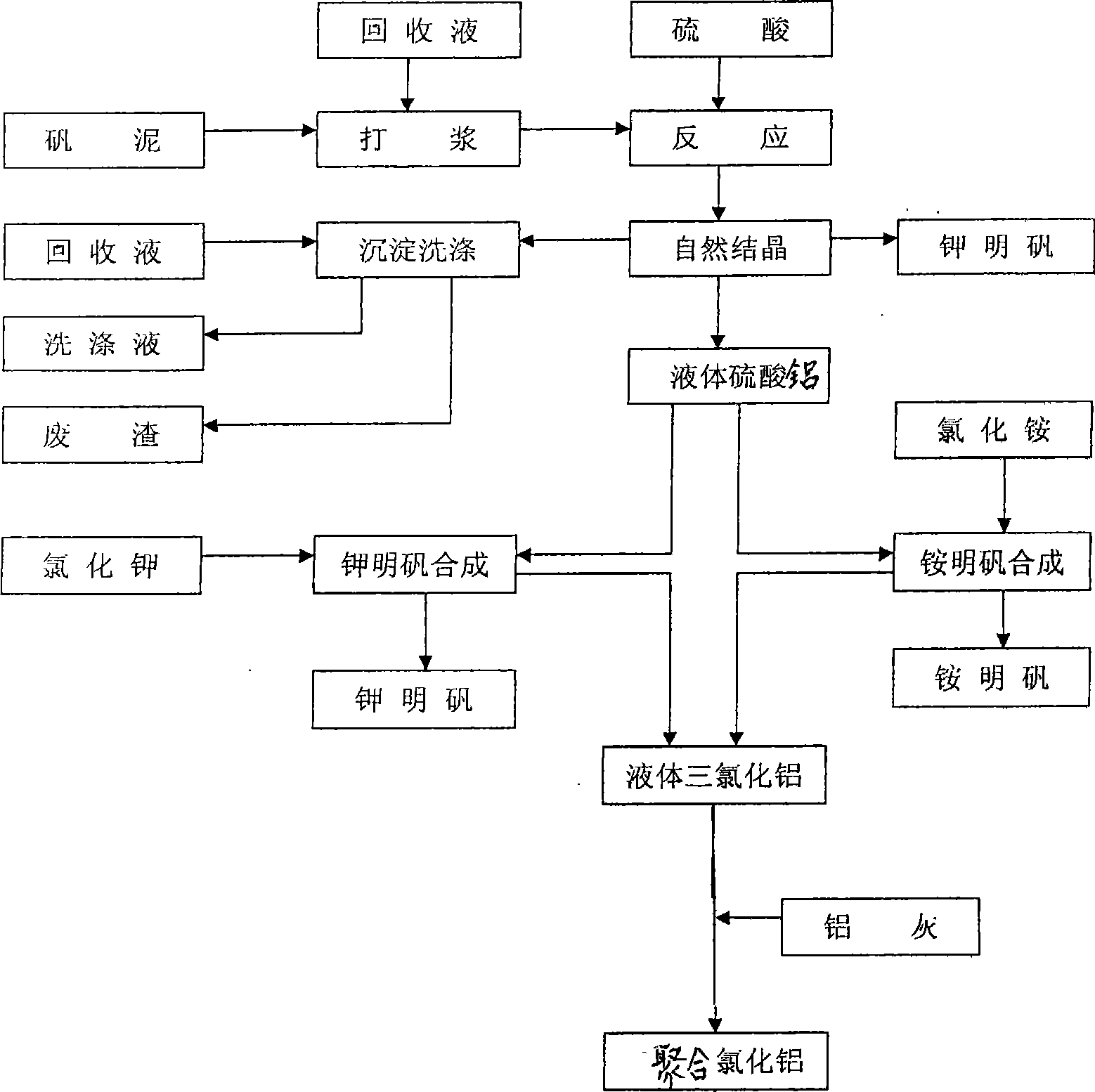

Method for joint production of potash alum or ammonium alum and polyaluminium chloride

A technology of polyaluminum chloride and potassium alum, which is applied in the direction of aluminum chloride, aluminum halide, aluminum sulfate, etc., to achieve the effects of low production cost, less consumption, and reduced environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] 1. Take 2 tons of alum mud and 2 cubic meters of recovered liquid, put them into the beating tank, start the beating machine for beating, send the beaten slurry into the reactor, add 3 cubic meters of recovered liquid to dilute, and then add 2.6 tons of 93wt. % sulfuric acid, (sulfuric acid concentration 31.8%) reacted, after 12 hours of reaction, the reaction solution was properly diluted and placed in the crystallization tank, naturally settled and cooled to crystallize, separated aluminum sulfate solution and potassium alum, and the sediment at the bottom of the pond was washed, and the potassium alum was recovered , The slag is discarded, and the washing liquid is recovered. Add 0.54 tons of ammonium chloride to the above-mentioned obtained aluminum sulfate solution to react, leave it to stand for aging crystallization, separate the liquid from the solid, the solid is ammonium alum, and the liquid is aluminum trichloride, so that the ammonium alum does not contain al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com