Process for producing low-density malto dextrine

A maltodextrin, low-density technology, applied in biochemical equipment and methods, bioreactors/fermenters for specific purposes, biochemical instruments, etc., can solve the problems of maltodextrin precision and dispersibility that cannot meet new demands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

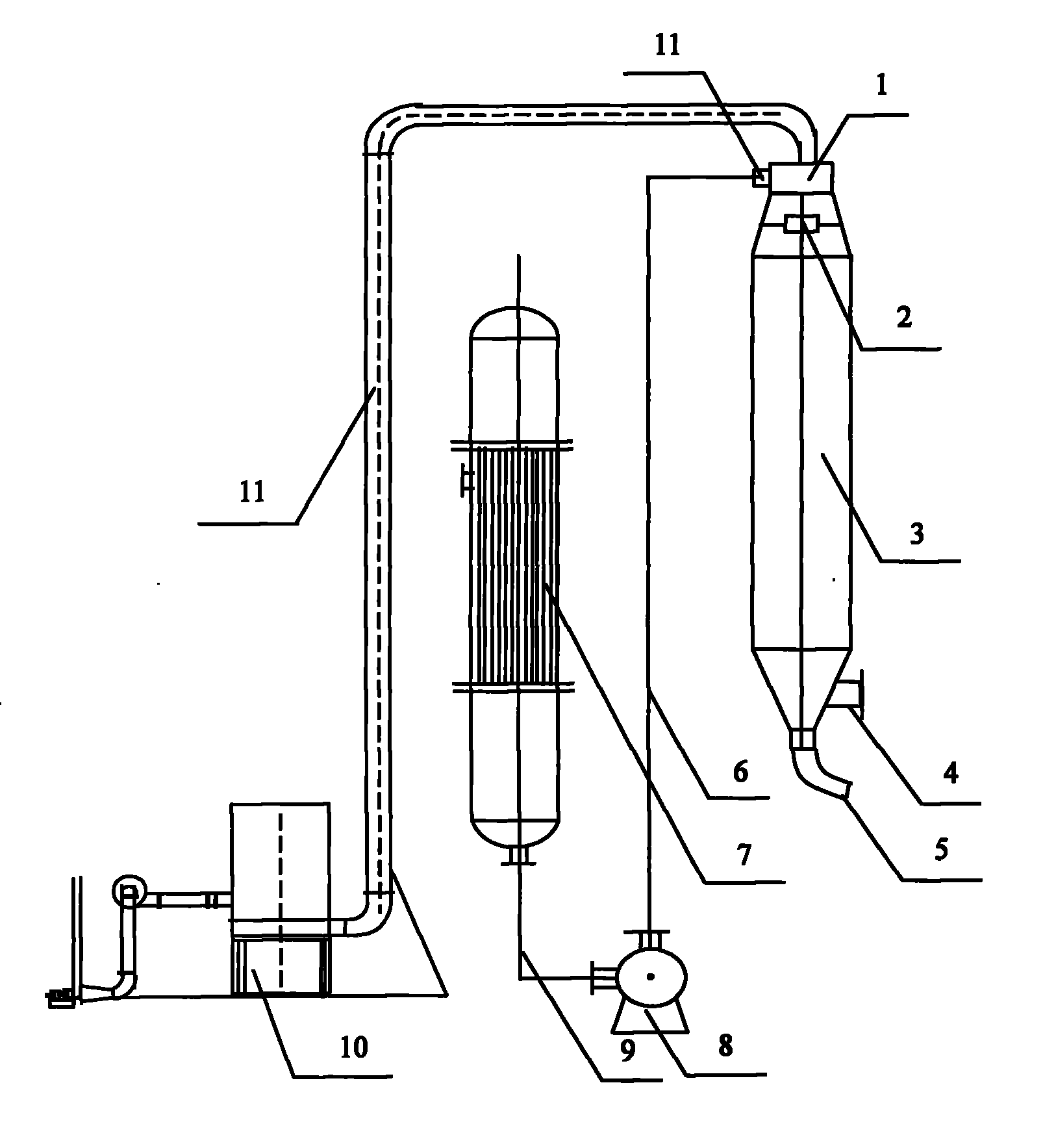

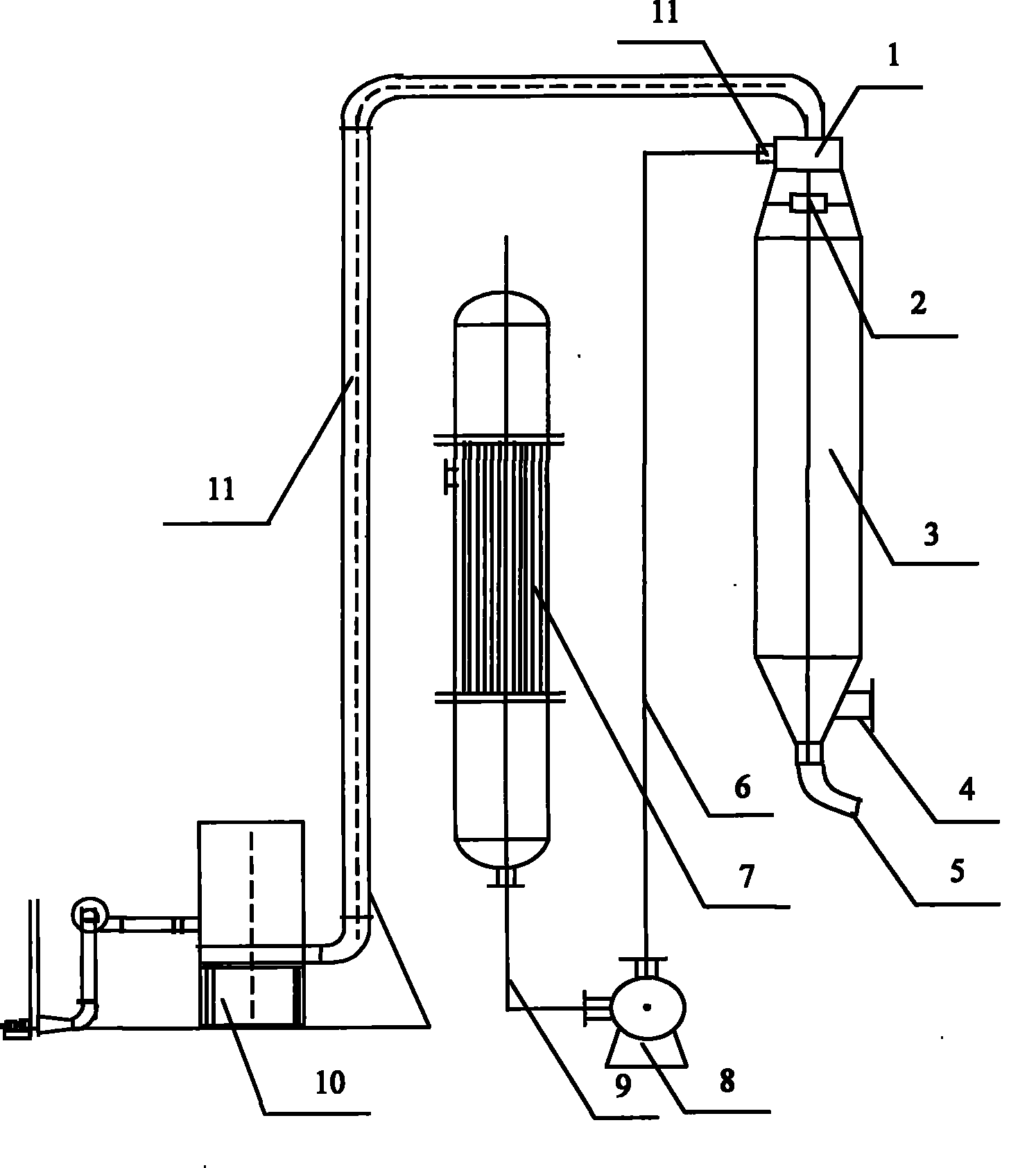

[0017] As shown in the figure, the spray dryer includes a gas heater 10, a drying tower 3, a heat distributor 1 and a sprayer 1. The gas heater 10 communicates with the heat distributor 1 at the top of the drying tower 3 through a hot air pipe 11, and the sprayer 2 is installed on The inner upper part of the drying tower 3 is dried. The spray dryer also includes a tube heater 7 , the tube heater 7 communicates with the feed pump 8 through the feed pipe 9 , and the feed pump 8 communicates with the feed port 12 of the drying tower 3 through the feed pipe 6 . The nozzle of the sprayer 3 is a spiral nozzle.

[0018] The specific process steps for preparing maltodextrin are as follows:

[0019] (1) Sizing: Use 45°C hot water to adjust starch milk with a mass percentage concentration of 25%, pH = 3, add α-high temperature amylase, and stir at 0.30Kg / t to make the slurry fluidity in good condition;

[0020] (2) Injection liquefaction: use a low-pressure injector with material and...

Embodiment 2

[0025] The spray dryer used was the same as that used in Example 1.

[0026] The specific process steps for preparing maltodextrin are as follows:

[0027] (1) Sizing: use 55°C hot water to adjust the starch milk with a mass percentage concentration of 40%, pH = 5, add α-high temperature amylase, the amount of enzyme added is 0.40Kg / t, stir to make the slurry flow sex is in good condition;

[0028] (2) Injection liquefaction: adopt a low-pressure injector with material and gas, the material pressure is 0.3mPa, the steam pressure is 0.6mPa, the first injection temperature is 110°C, and the injection time is 12min. After the first injection, maintain 95°C for 90min and control The DE value is 20%, the second injection temperature is 135°C, and the injection time is 5 minutes;

[0029] (3) Microporous refining: After the second injection, cool the liquefied liquid to below 90°C, add activated carbon with a mass percentage of 1% to stir and adsorb for 30 minutes, and filter thro...

Embodiment 3

[0033] The spray dryer used was the same as that used in Example 1.

[0034] The specific process steps for preparing maltodextrin are as follows:

[0035] (1) Sizing: Use 48°C hot water to adjust starch milk with a mass percentage concentration of 30%, pH=4, add α-high temperature amylase, and stir at 0.35Kg / t to make the slurry fluidity in good condition;

[0036] (2) Injection liquefaction: use a low-pressure injector with material and gas, the material pressure is 0.3mPa, the steam pressure is 0.6mPa, the first injection temperature is 107°C, and the injection time is 10min. After the first injection, maintain 95°C for 70min and control The DE value is 18%, the second injection temperature is 135°C, and the injection time is 5 minutes;

[0037] (3) Microporous refinement: After the second injection, cool the liquefied liquid to below 90°C, add activated carbon with a mass percentage of 1% to stir and adsorb for 30 minutes, and filter through a microporous filter to remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com