Method for successively preparing icariside II and icaritin by taking icariin as raw material

A technology of icariin and icariin, applied in sugar derivatives, organic chemistry, fermentation, etc., can solve the problem of low conversion rate of icariin II, high difficulty in separation and purification, and difficulty in large-scale preparation and other issues, to achieve the effect of low equipment requirements, lower production costs, and simple production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 Expression and purification of trans glycoside hydrolase

[0058] (1), construction of recombinant Escherichia coli

[0059] 1. Acquisition of trans-glycoside hydrolase gene

[0060] Activate the Clostridium stercorarium DSM8532 strain, collect the cells, and extract DNA according to the instructions of the Column Plasmid DNA Small Extraction Kit (purchased from Shanghai Sangong), and use the extracted DNA as a template for PCR.

[0061] The enzyme cutting sites used for constructing the plasmid are as follows: XhoI and BamHI;

[0062] The upstream and downstream primers are: Forwardprimer AGCTGAAGAACGCGGAATGA

[0063] Reverse primer AGCATTCGATGCCGAGCTTA

[0064] (All primers were synthesized by Shanghai Sangon)

[0065] PCR conditions of the gene: 30-35 cycles according to the following conditions, denaturation at 98°C for 10s, annealing at 65°C for 5s, extension at 72°C for 10s.

[0066] 2. Construction and transformation of recombinant plasmids

[...

Embodiment 2

[0072] Example 2 Preparation of Icariside II and Icaritin

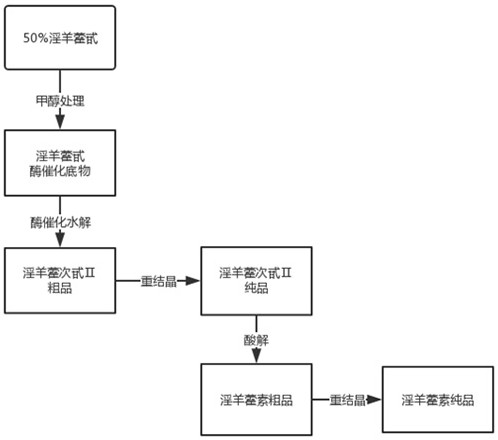

[0073] Preparation process of icariside II and icariin figure 1 shown.

[0074] 1. Preparation of Icariside II

[0075] 1. Add 20Kg of methanol-treated icariin into a 500L stirring mixer, and simultaneously add 400L of 20% ethanol solution by volume, and stir evenly.

[0076] 2. Thoroughly homogenize the uniformly stirred material liquid through a high-pressure homogenizer, and the pressure of the high-pressure homogenizer is controlled at 30MP. After the homogenate is completed, it is discharged into a 500L temperature-controlled tilting reactor. Turn on the heating and stirring of the reactor to control the temperature at 55° C. and the pH at 6.

[0077] 3. After the temperature of the reaction system is stably controlled at 55°C, weigh 1Kg of the hydrolase prepared in Example 1, add 10Kg of pure water to dissolve completely, then slowly add it to the reaction system, stir for half an hour, stop stirring, and le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com