Electroconductive particle placement sheet and anisotropic elctroconductive film

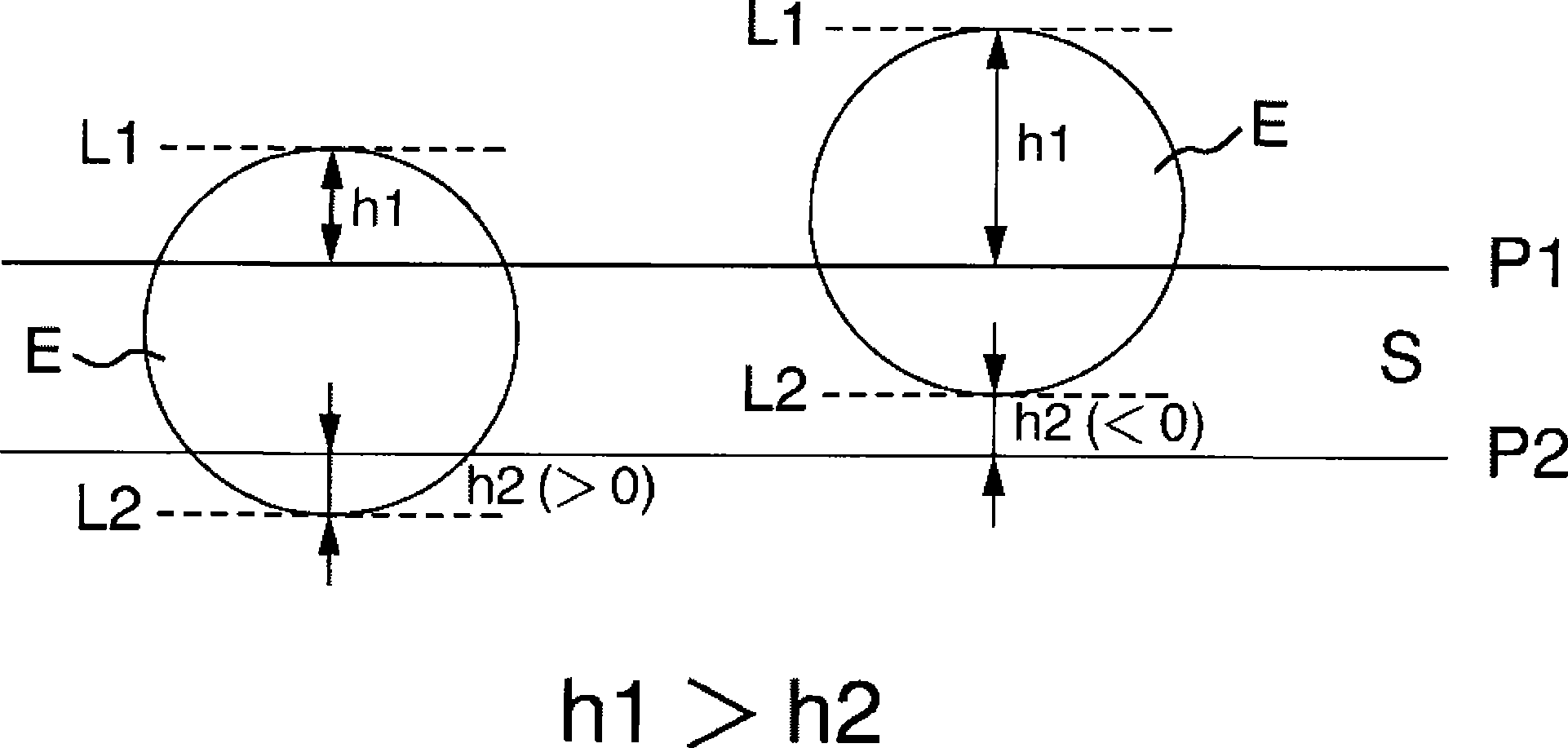

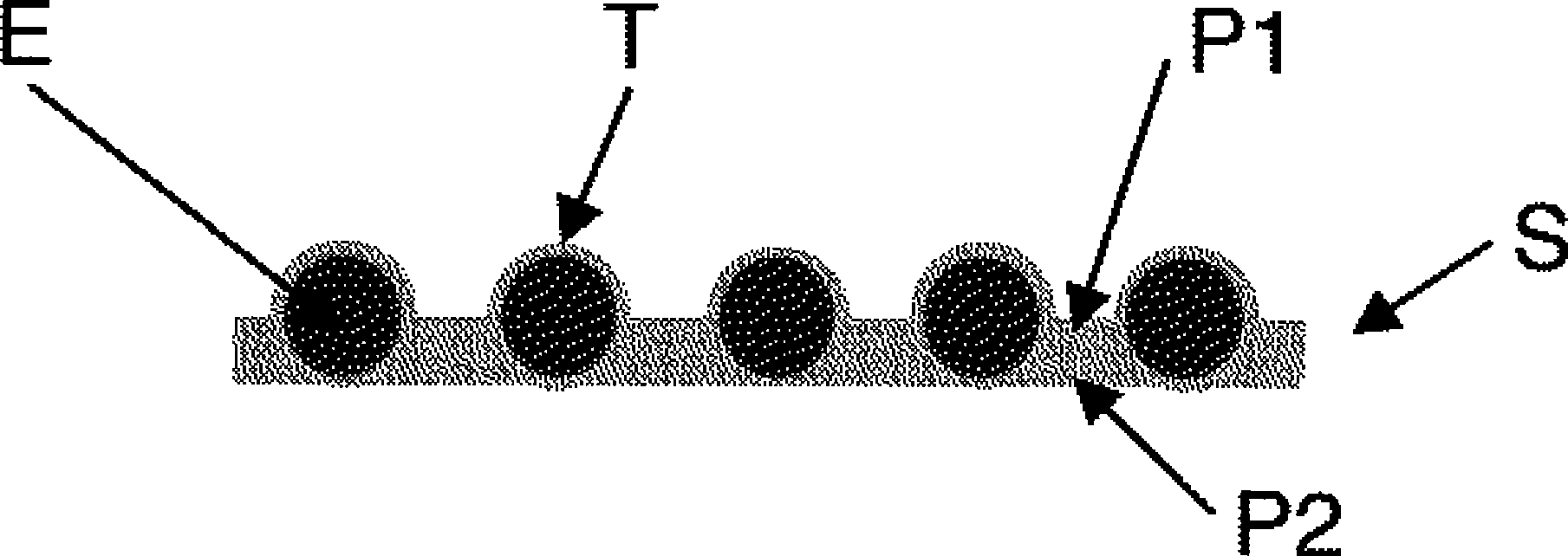

一种导电颗粒、薄片的技术,应用在导电连接、导电粘合剂、薄膜/薄片状的粘合剂等方向,能够解决连接缺陷、导电颗粒易于脱落、绝缘膜薄膜化限制等问题,达到绝缘性高、连接可靠性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

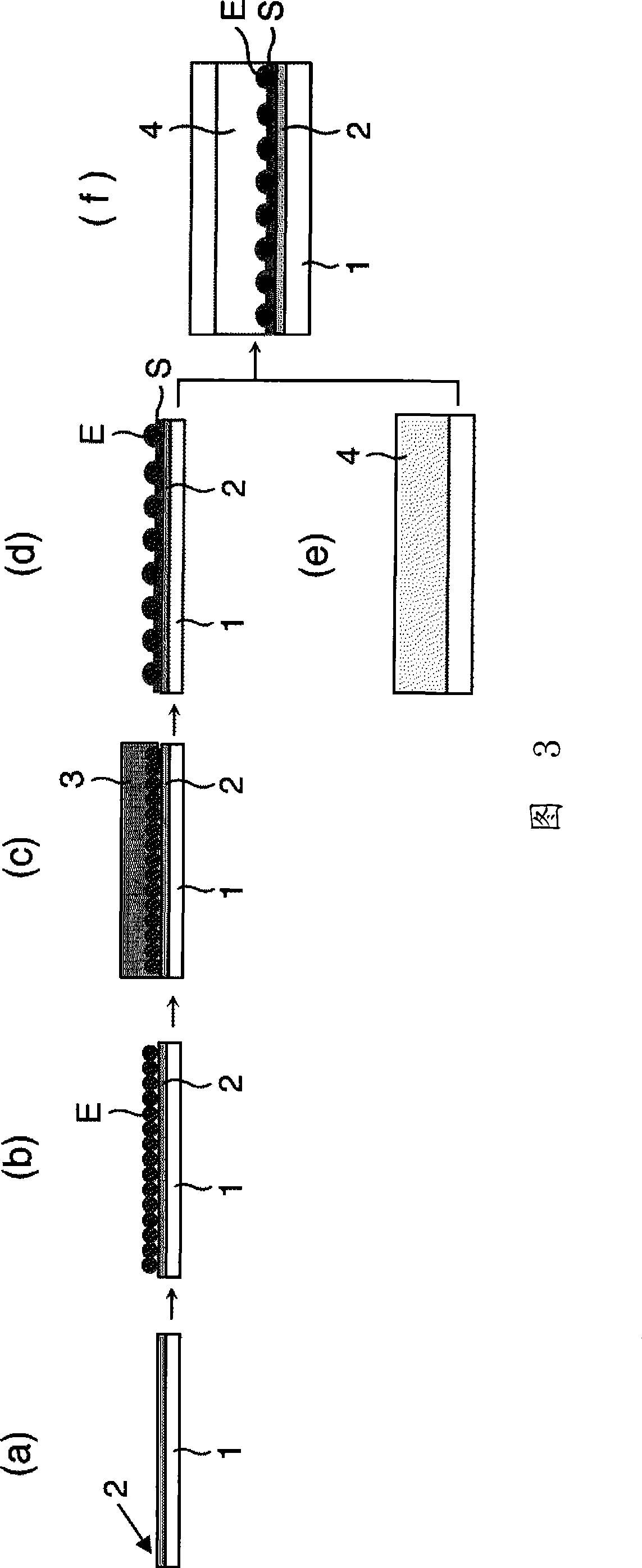

Method used

Image

Examples

Embodiment 1

[0137]Mixed phenolic oxygen resin (manufactured by InChem, trade name: PKHC) 80 parts by mass, bisphenol A type liquid epoxy resin (manufactured by Asahi Kasei Chemical Co., Ltd., trade name: AER2603) 20 parts by mass, silane coupling agent (Japan Unicar Made by the company, trade name: A-187) 0.25 parts by mass, ethyl acetate 300 parts by mass, to obtain a varnish for an insulating resin sheet. The melt viscosity at 180° C. of the insulating resin sheet obtained by removing the solvent from the insulating resin sheet with varnish was 1500 Pa·s.

[0138] An acrylic polymer diluted with ethyl acetate to 5% by mass of the resin component was coated onto a 100 μm non-stretched copolymer polypropylene film using a knife coater, and dried at 80° C. for 10 minutes to form an adhesive layer with a thickness of 1 μm. The acrylic polymer used here is to use azobisisobutyronitrile as initiator, 62 mass parts of methyl acrylate, 30.6 mass parts of 2-ethylhexyl acrylate, 7 mass parts of 2...

Embodiment 2

[0150] As the insulating resin sheet, a phenolic resin (manufactured by InChem Corporation, trade name: PKHB, melt viscosity at 180° C. is 980 Pa·s) was used alone, the average particle diameter of the conductive particles was changed to 3 μm, and the filling rate was changed to 82%. Otherwise, a conductive particle-filled sheet was obtained in the same manner as in Example 1, and a conductive particle-arranged sheet (referred to as a conductive particle-arranged sheet B) was obtained in the same manner as in Example 1 except that the draw ratio was 2.7 times.

[0151] When the obtained conductive particle arrangement sheet B was observed using a scanning electron microscope, the conductive particles were present in the insulating resin sheet, the portion of the insulating resin sheet without conductive particles was approximately smooth, and the conductive particles protruded greatly on one side of the insulating resin sheet. Its protruding portion is covered with an insulatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com