Lubricating oil viscosity index improver and preparation thereof

A technology for improving viscosity index and lubricating oil, which is applied in lubricating compositions, additives, petroleum industry, etc. It can solve the problem of decreased shear stability and achieve good thickening ability, good compatibility, and excellent shear stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: 3500 milliliters of pure cyclohexane, 5.5 milliliters of tetrahydrofuran, and 6.4 mmol of n-butyllithium were added to a 10-liter polymerization kettle replaced with pure nitrogen, and the temperature was raised to 60 ° C under stirring, and then 56 g of styrene and 224g of butadiene monomer mixture is continuously added to the polymerization tank, the feeding time is controlled to be 45-75 minutes, the polymerization temperature is 60-85°C, and the monomers are added and then reacted for 0-15 minutes, and then 13.4mmol of diethylene is added Benzene is used for coupling reaction, the temperature of the coupling reaction is controlled at 60-85°C, and the coupling reaction time is 30-60 minutes. After the coupling reaction is completed, the glue is introduced into the hydrogenation tank, and dimethyl phthalate is used as a cocatalyst Dicyclopentadiene titanium dichloride is the main catalyst, and the hydrogenation reaction is carried out under the conditions of...

Embodiment 2

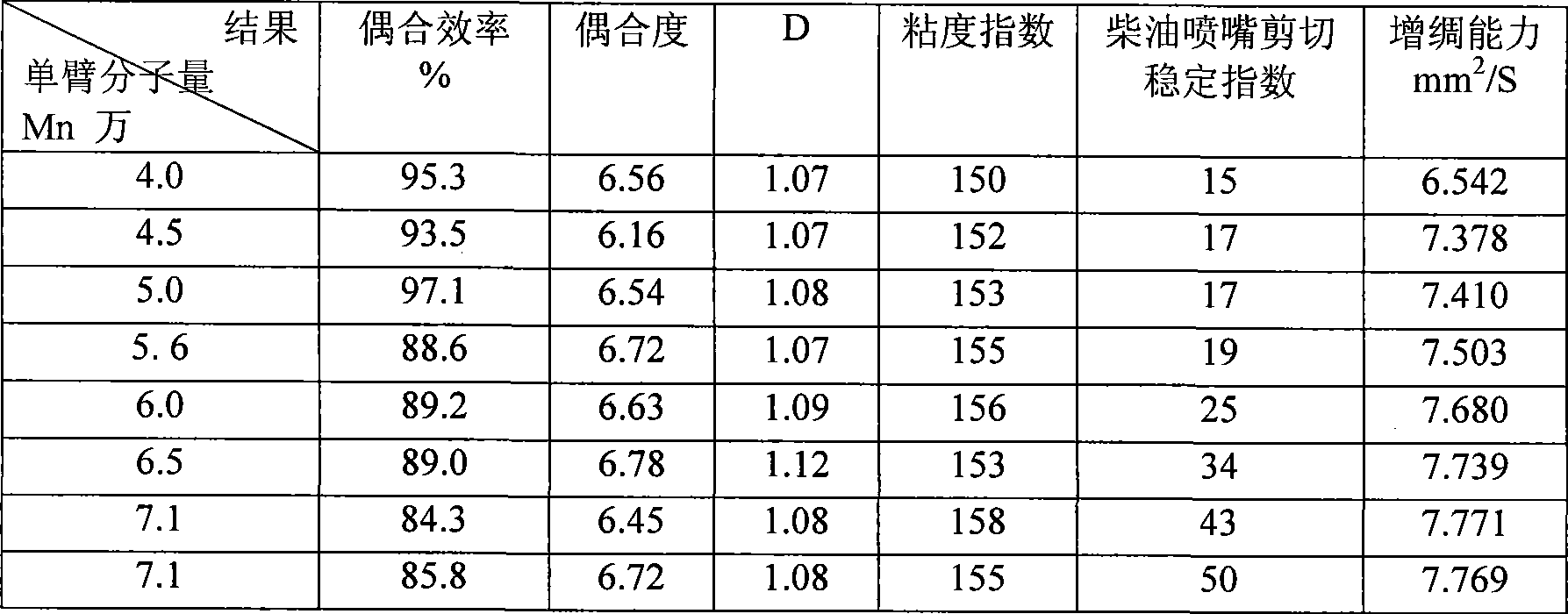

[0052] Embodiment 2: The preparation process is the same as in Example 1, changing the addition amount of initiator n-butyllithium to synthesize polymers with different single-arm molecular weights, and keeping the molar ratio of n-butyllithium and divinylbenzene in the coupling reaction as 2.2. The experimental results are shown in Table 1.

[0053] Table 1 Results of polymer modified lubricating oils with different single-arm molecular weights

[0054]

Embodiment 3

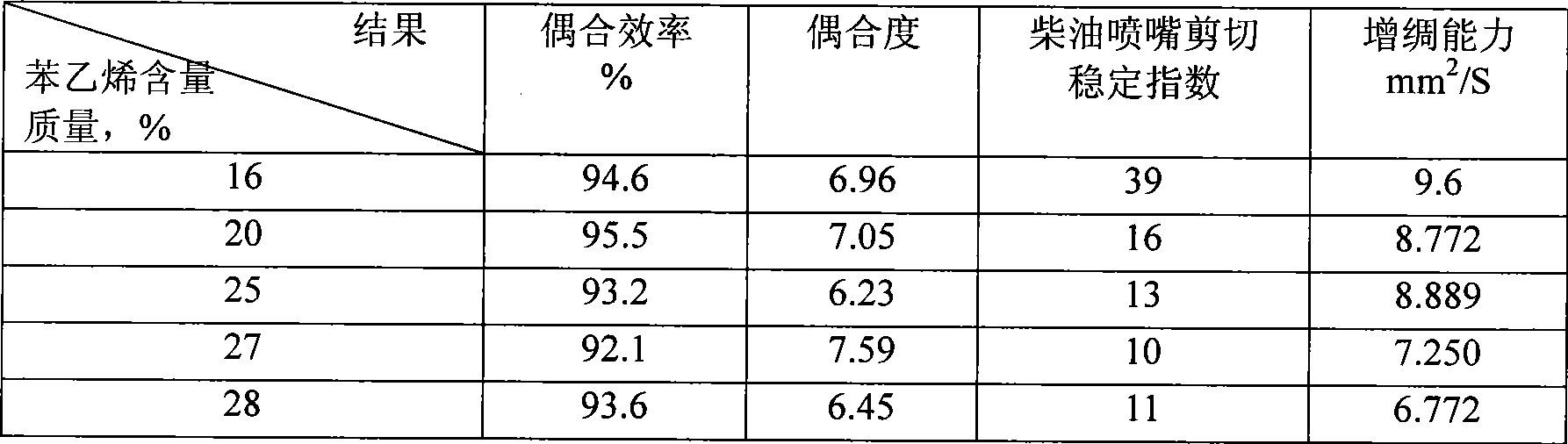

[0055] Example 3: The preparation process is the same as in Example 1, but the ratio of styrene and butadiene is changed to synthesize polymers with different styrene contents. The experimental results are shown in Table 2.

[0056] Table 2 Results of polymer modified lubricating oils with different styrene contents

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com