Cell electrofusion chip and method for manufacturing the same

An electrofusion and cell technology, applied in biochemical equipment and methods, tissue cell/virus culture devices, stress-stimulated microbial growth methods, etc. Weak oxidation ability, poor visibility enhancement, etc., to achieve the effect of improving electric field inductive force, improving chemical corrosion resistance, and good optical visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

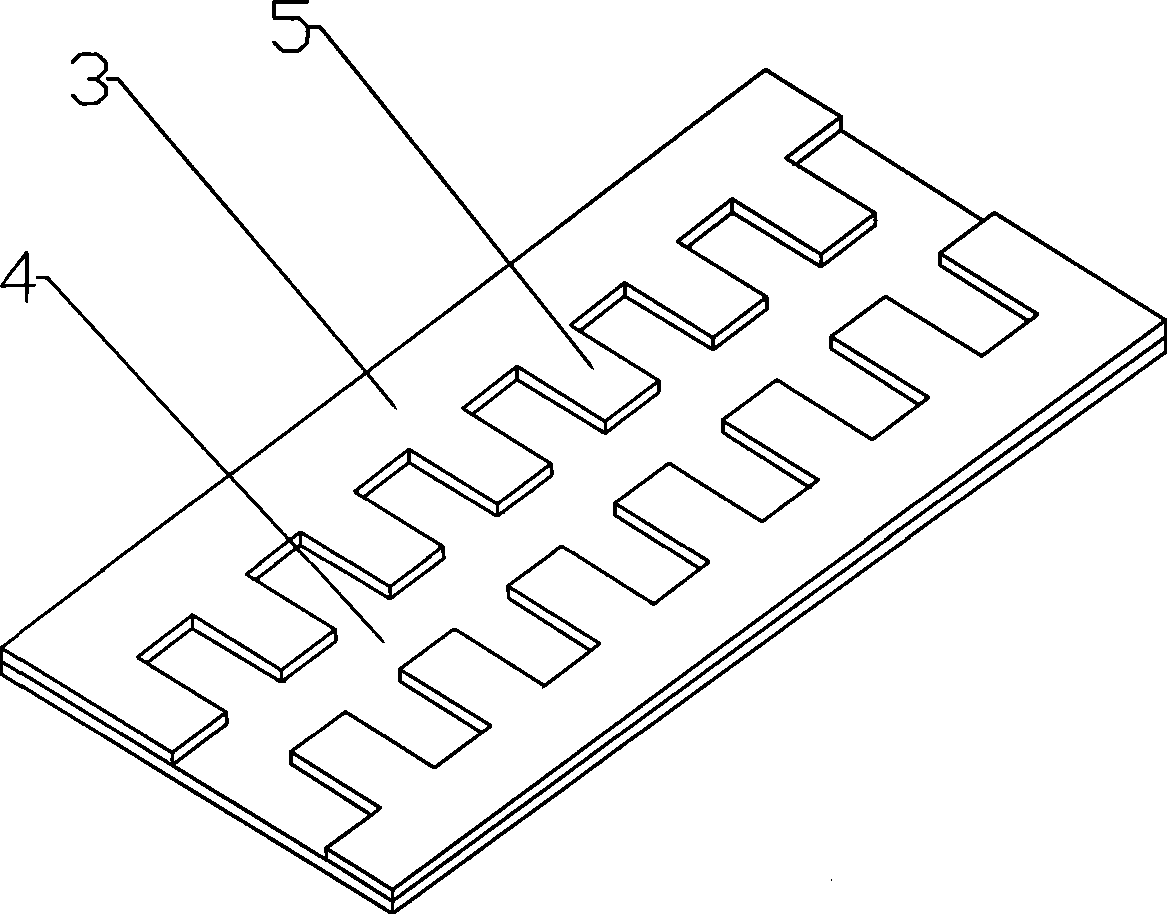

[0037] figure 1 It is a schematic structural diagram of a cell electrofusion chip; figure 1 As shown: the cell electrofusion chip is formed by bonding a silicon wafer 1 and a glass wafer 2, a microelectrode group 3 is arranged on the silicon wafer 1, and a plurality of microelectrodes 5 are arranged on the microelectrode group 3, and the microelectrode group 3 A signal lead-out line is provided to connect with an external electrical control signal. The microelectrodes 5 are arranged on one side of the microelectrode group 3 in a zigzag shape. A continuous microchannel 4; the thickness of the silicon chip 1 is 40-60 μm, and the thickness of the glass sheet 2 is 500-1000 μm; the signal lead-out line of the microelectrode 5 is made of gold wire.

[0038] The microelectrodes 5 can also be arranged on the microelectrode group 3 in a sharp-edged zigzag shape or other shapes.

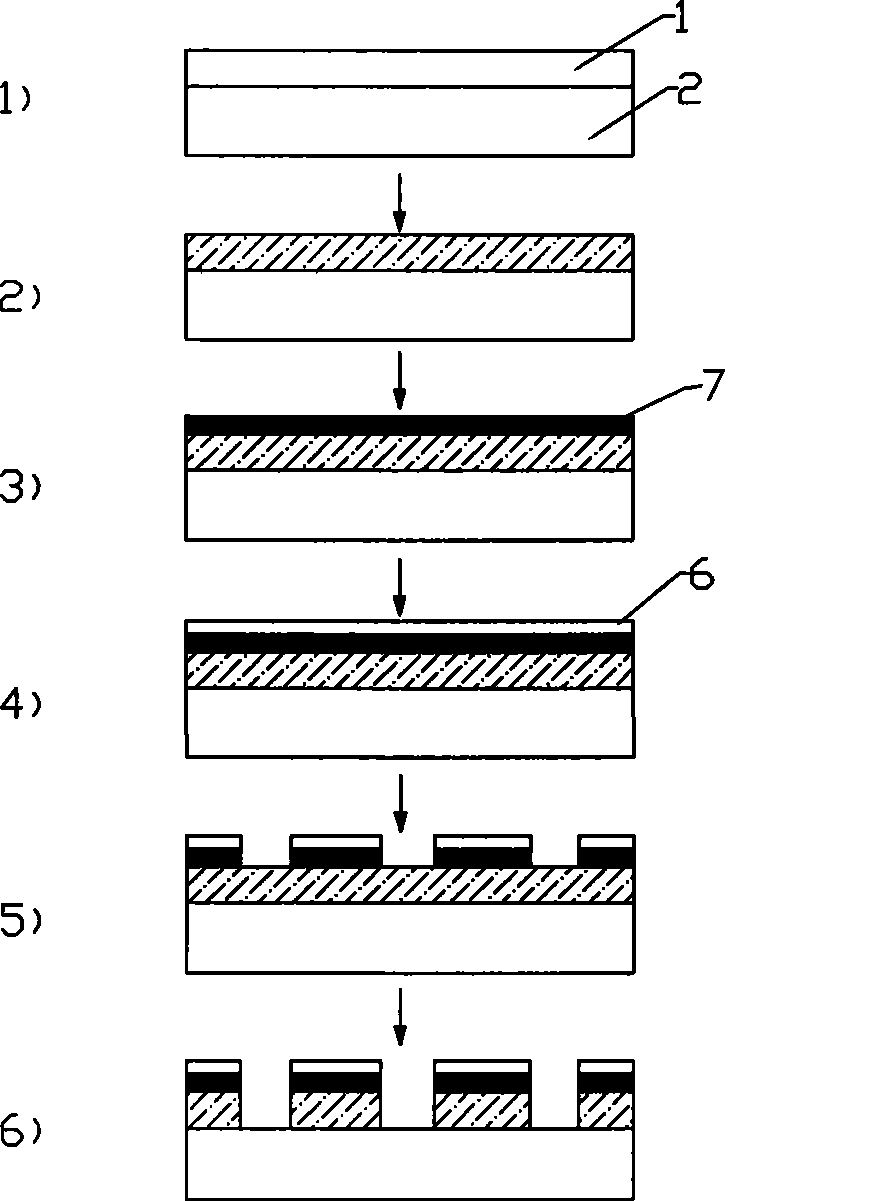

[0039] figure 2 Schematic diagram of the fabrication process for the cell electrofusion chip, such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com