Method and apparatus for electromagnetic drive of rectilinear movement

A technology of linear motion and electromagnetic drive, applied in the direction of electromagnets, electromagnets with armatures, etc., can solve the problems of hydraulic workstations occupying more space, complex hydraulic oil circuit mechanisms, and low energy conversion efficiency, and achieve high energy conversion efficiency , The effect of material cost reduction and simple efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

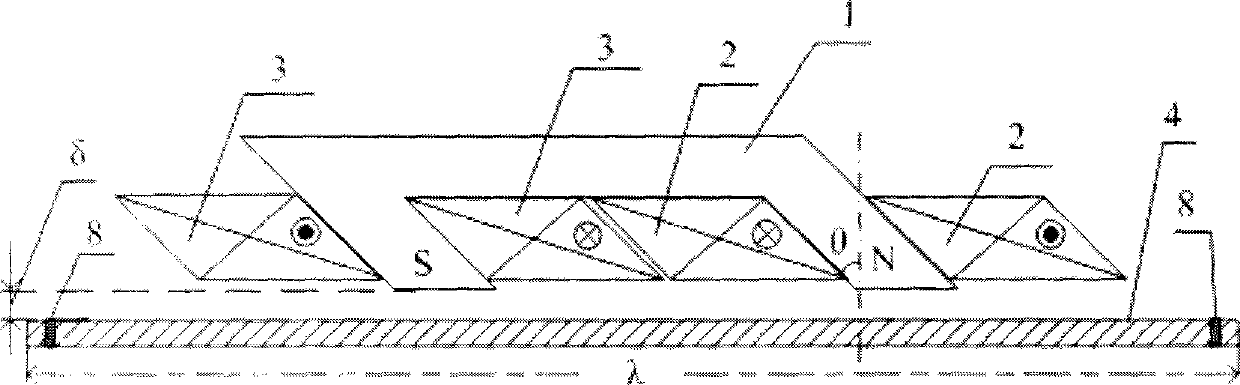

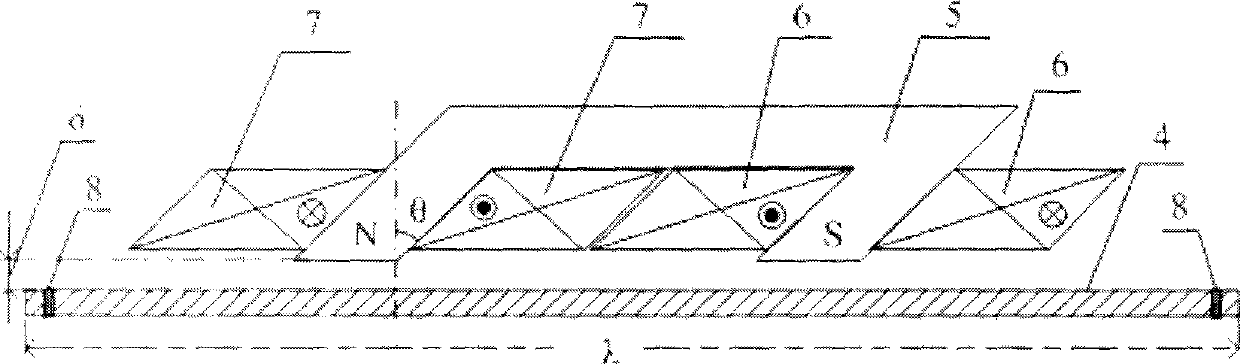

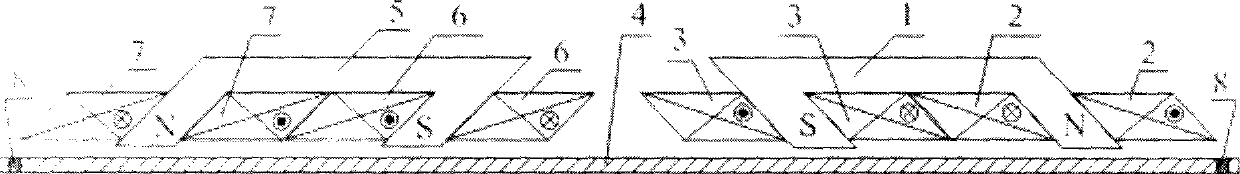

[0038] The structure of the present invention see figure 1 . The main structure is composed of a U-shaped electromagnet and a metal conductor. The two magnetic poles of the U-shaped electromagnet form an oblique angle of 45 degrees. In general, as long as the space size permits, the U-shaped electromagnet can be wound with coil windings along the three sides of the U-shaped iron core, effectively constraining the direction of the magnetic field in the iron core and reducing the loss of the magnetic field. Also for the symmetry of the design, the rationality of the use of electromagnetic energy, and the balance of the electromagnetic induction force, in actual use, two U-shaped electromagnets are combined with a metal conductor, and the layout is mirrored in the horizontal direction of the conductor. Or the object layout in the vertical direction of the conductor, as the basic power source or basic power unit. In this way, the basic power units can be combined arbitrarily acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com