Green algae oral liquid production method

The technology of a green algae oral liquid and a production method is applied in the field of biological health care products, and can solve the problems of short shelf life, heavy fishy smell and poor taste of green algae products, and achieve moderate sweetness and sourness, rich nutrients, and enhanced immunity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

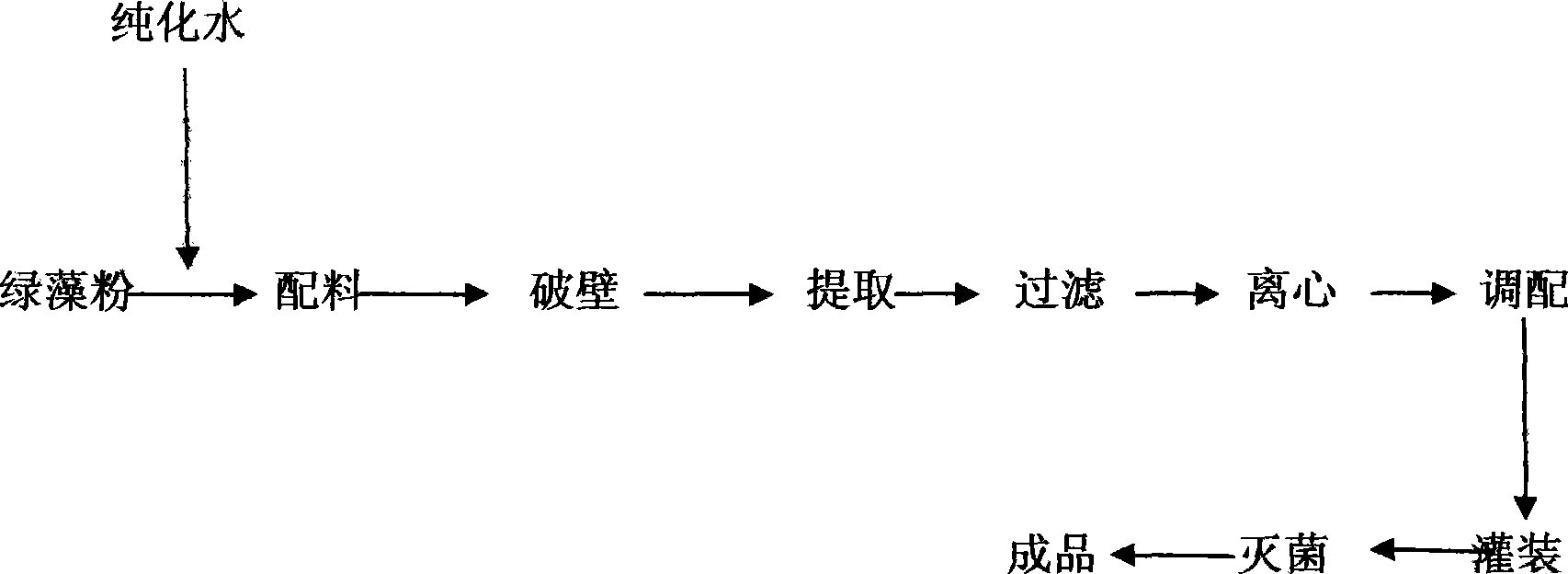

[0015] see figure 1 Process flow chart of the present invention:

[0016] Step 1: Mix and stir 20 kg of Chlorella pyrenoidosa powder produced by Jiangxi Pinshengyuan Bioengineering Co., Ltd. according to the proportion (1:20) of Chlorella powder and purified water, and soak at a temperature of 50°C for 1 hour;

[0017] Step 2: The algal water mixture in step 1 is subjected to high-pressure crushing once at 70Mpa through a high-pressure homogenizer;

[0018] Step 3: Add 0.3 million U of cellulase and 0.2 million U of pectinase to the algal water mixture in step 2 produced by Guangzhou Yuantian Enzyme Preparation Factory. Algae cells were pretreated for 1.5h;

[0019] Step 4: Transfer the algae solution after the broken wall in step 3 to the extraction tank for extraction, add 20,000 U of papain produced by Guangzhou Yuantian Enzyme Preparation Factory for each gram of green algae at pH: 6.0-7.0; temperature 50°C , Extraction 1.5, the algae solution is constantly stirred duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com