Kangfulingshuan medicine production technique

A preparation process and technology for medicines, applied in the directions of anti-infective drugs, suppository delivery, drug combination, etc., can solve problems such as drug effect influence, non-conformity, failure to reach frying temperature, etc., and achieve process environmental protection, convenient use, and drug efficacy. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Preparation process steps for the production of Kangfuling suppository: crush 19.2g of borneol and 27.4g of catechin into fine powder for later use; 674g of rhubarb coarse powder, add 95% ethanol for reflux extraction twice, each time for 1.5 hours, reclaim ethanol, vacuum concentrate, vacuum Dry and crush for later use; take 274g of comfrey, soak it in 657.5ml of sesame oil for 72 hours, filter off the comfrey, when the remaining sesame oil is less than 493.2ml, use heated sesame oil to make up to 493.2ml, add 330g of paraffin wax, 110g of beeswax, and semi-synthetic fatty acid lipids , heated to 45°C, stirred, added borneol, catechin fine powder and rhubarb dry paste powder, stirred and mixed, potted, each 2.5g, made into 1000 suppositories.

Embodiment 2

[0012] Preparation process steps for the production of Kangfuling suppository: 384g of borneol and 548g of catechin powder are finely powdered, 13480g of rhubarb is taken as a coarse powder, and 95% ethanol is added to reflux extraction for 2 times, each time for 1.5 hours, ethanol is recovered, vacuum concentrated, vacuum dried, smash. Take 5480g of comfrey, soak in 13150ml of sesame oil for 72 hours, filter out the comfrey, if the remaining sesame oil is less than 9864ml, use heated sesame oil to make up to 9864ml, add 6600g of paraffin wax, 2200g of beeswax, add semi-synthetic fatty acid ester, and heat to 45°C , stir, add cold slices, catechin fine powder and rhubarb dry paste powder, stir and mix well, potting, 2.5g per capsule, and make 20,000 suppositories.

experiment example

[0014] In order to verify whether the process is reasonable and feasible after the process change, the present invention has carried out a pharmacodynamic test on the Kangfuling suppository before and after the process change through Changchun University of Traditional Chinese Medicine.

[0015] Method and Results

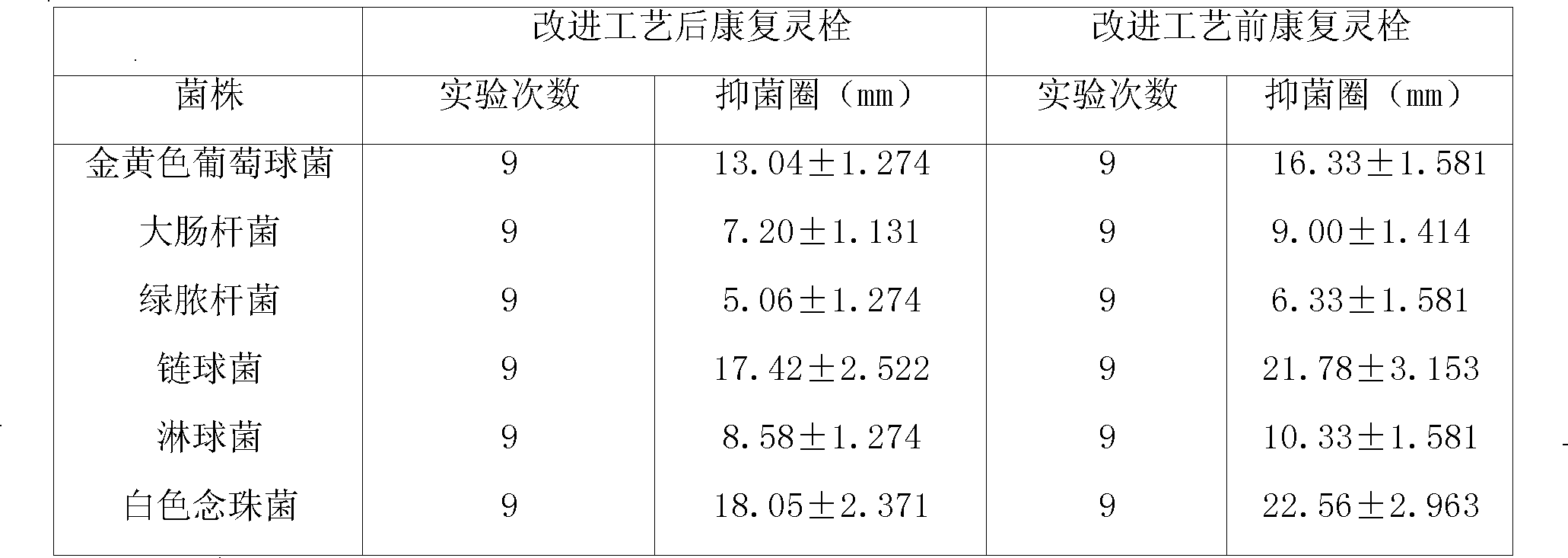

[0016] 1. Comparison of antibacterial and insecticidal effects of two Fufuling suppositories

[0017] 1. Tube and plate method:

[0018] Two kinds of Kangfuling Suppositories were sterilized at 80°C for 2 hours separately, and the strains were inoculated on suitable medium (broth blood medium, chocolate blood medium, broth agar medium, blood agar medium, Sabouraud culture medium, etc.) base, liver-ptone-sugar medium), respectively diluted to 900,000 bacteria / ml, diluted to 50,000 Candida albicans / ml, and added 0.25g of Kangfuling to the tube dish of each bacterial strain culture dish Suppository, cultured at 37°C for 18 hours, measured the inhibition zone, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com