Method for producing high purity vanadic anhydride

A technology of vanadium pentoxide and a production method, applied in vanadium oxide and other directions, can solve the problems of uneven product quality, harm, excessive impurity content, etc., and achieve the effects of high purity, simple production equipment and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Add 100Kg of ammonium metavanadate into 350Kg of water, add ammonia water when heated to 80°C, and add while stirring until the ammonium metavanadate is completely dissolved;

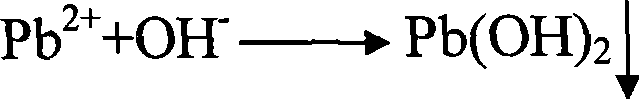

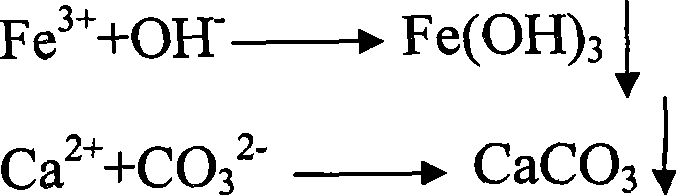

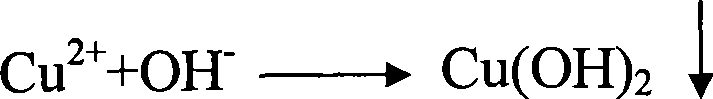

[0026] 2) Add an appropriate amount of alum to remove Si in the solution, add a mixture of sodium hydroxide and sodium carbonate to remove elements such as Pb, Fe, Ca, Cu, Ni, As, Cr, Cd, and then undergo natural precipitation and clarification.

[0027] 3) Remove impurities from the supernatant, and when heated to 80°C, add oxidant KClO to the solution 3 , add while stirring, the divalent vanadium in the solution is oxidized to pentavalent vanadium, KClO 3 The addition amount is 1.5kg;

[0028] 4) Heat the fully oxidized solution to 95°C in the reaction kettle, add sulfuric acid to adjust the pH value to 2.5 and stir at a speed of 100r / min until the brown solid is completely precipitated;

[0029] 5) then vacuum filtration, dehydration and drying to obtain a brown powdery solid;

[0030] 6...

Embodiment 2

[0034] 1) Add 100Kg of ammonium metavanadate to 300Kg of water, add ammonia water when heated to 90°C, and add while stirring until the ammonium metavanadate is completely dissolved;

[0035] 2) the method identical with embodiment 1 removes the contained impurity of ammonium metavanadate;

[0036] 3) When the impurity-removed supernatant is heated to 90°C, add the oxidizing agent KClO to the solution 3 , add while stirring, the divalent vanadium in the solution is oxidized to pentavalent vanadium, KClO 3 The addition amount is 1.8kg;

[0037] 4) Heat the fully oxidized solution to 90°C in the reaction kettle, add sulfuric acid to adjust the pH value to 3 and stir at a speed of 120r / min until the brown solid is completely precipitated;

[0038] 5) then vacuum filtration, dehydration and drying to obtain a brown powdery solid;

[0039] 6) Calcining the dried powdery solid in an oxidizing atmosphere at a temperature of 530° C. for 2.5 hours.

[0040] All dissolution, separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com