Synergist for edible fungus culture medium and preparation and use method thereof

A technology of synergist and compost, applied in botany equipment and methods, applications, organic fertilizers, etc., can solve the problems of increased production cost of edible fungi, affecting the permeability of cultivating materials, difficulty in storage of wheat bran, etc., and achieve growth Accelerated speed, obvious strain advantages, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

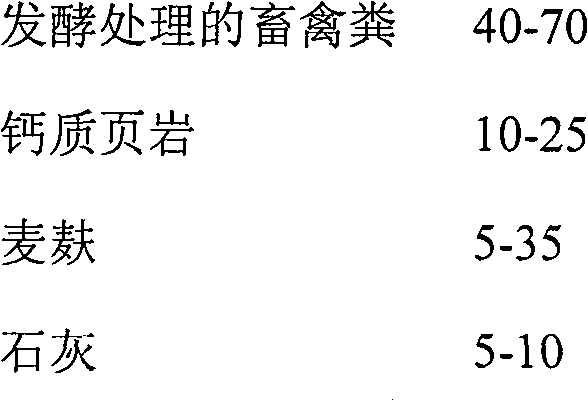

[0018] Embodiment 1: Preparation of synergist for edible fungus culture material

[0019] 1) deodorizing fermentation treatment of livestock and poultry manure: mix 5-30% weight of pine needles and 0.1-0.5% fermentation bacteria agent by weight of dry manure, add water and mix to make the moisture content 55-60%, with Knead into a ball by hand, loose by hand; then spread out, mix well, build a pile with a width of 0.8m, a height of 1.5m, and a pile of unlimited length for fermentation. Fermentation at natural temperature for 15-25 days, winter The fermentation time is 20-25 days, and 15-20 days in other seasons. During this period, every 8-10 days, when the temperature reaches 50-60°C, the pile is turned once, dried until the water content is below 20%, and pulverized for later use;

[0020] 2) Calcareous shale crushing: crush the calcareous shale into 0.3-0.6cm particles for later use;

[0021] 3) Synergist preparation: The synergist for edible fungus culture material is pre...

Embodiment 2

[0025] Embodiment 2: the usage method of synergist for edible mushroom culture material

[0026] The preparation (weight %) of edible mushroom culture medium: corncob 78%, gypsum 1%, sugar 1%, lime 1%, superphosphate 1%, the synergist 20% of No. 1-5 arbitrary formula in the embodiment 1 Mix the raw materials evenly according to the above ratio, add a certain amount of water to make the water content reach 55-60%, mix well, pack them in polyethylene cultivation bags, compact the bags, and each bag contains about 3 kg of wet materials. High pressure 1.5atm, sterilize for 90min or normal pressure for 10h, take out after sterilization, and cool to below 30℃ under natural temperature. Inoculate any one of Pleurotus ostreatus, yellow elm mushroom, Coprinus comatus and Pleurotus osmanthus under sterile conditions, and cultivate at 20-25°C for 30-45 days. Observe mycelium germination and feeding status, mycelium thick white degree, pollution rate, and calculate biological transformat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com