Method for preparing middle chrome pigment

A technology of pigment and chrome yellow, applied in the field of preparation of chrome yellow pigment in lead chromate, can solve the problems of poor heat resistance and light resistance, and achieve the effects of good heat resistance, cost reduction and easy dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

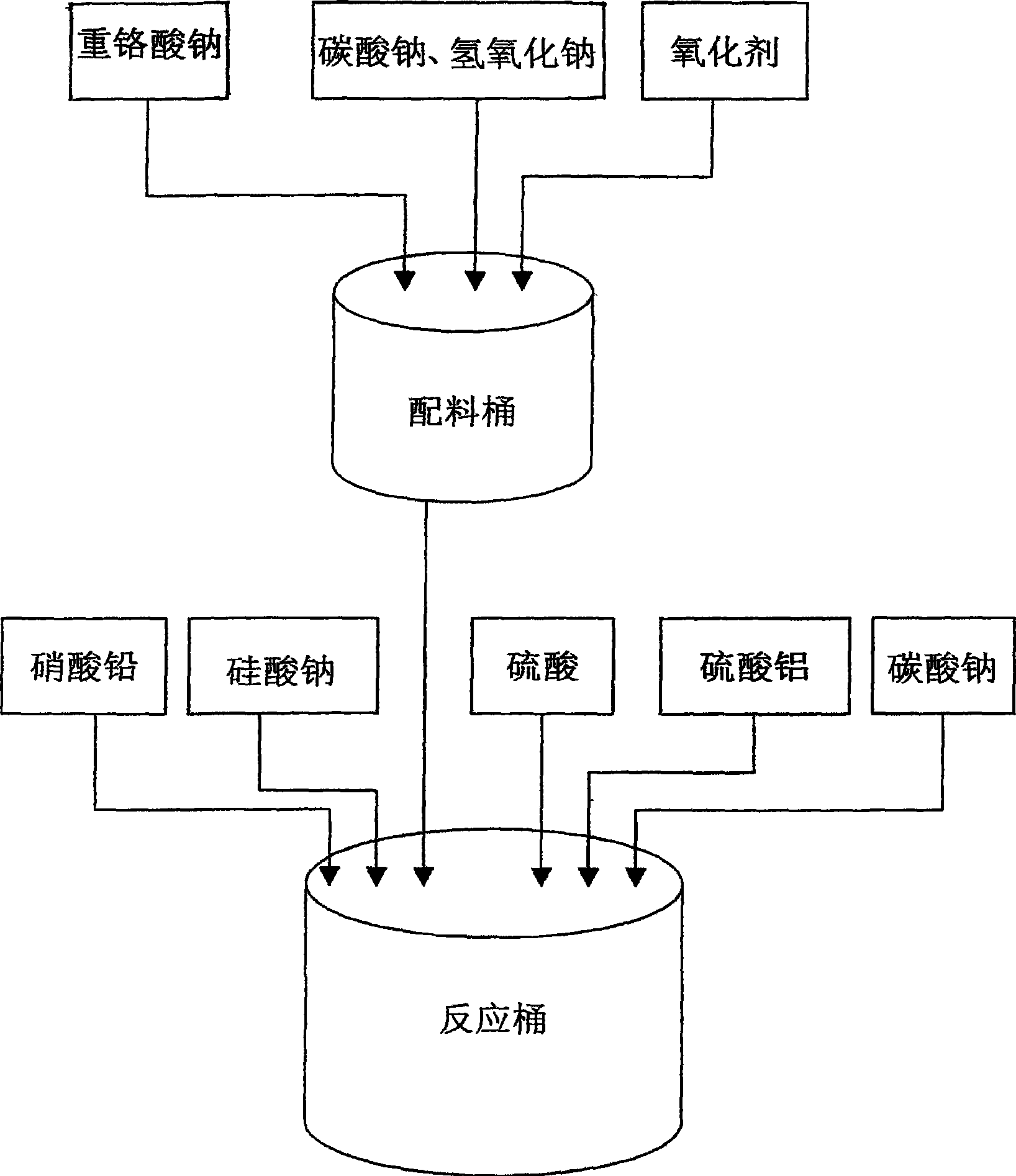

Method used

Image

Examples

Embodiment 1

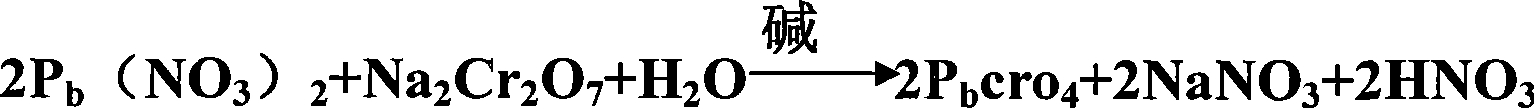

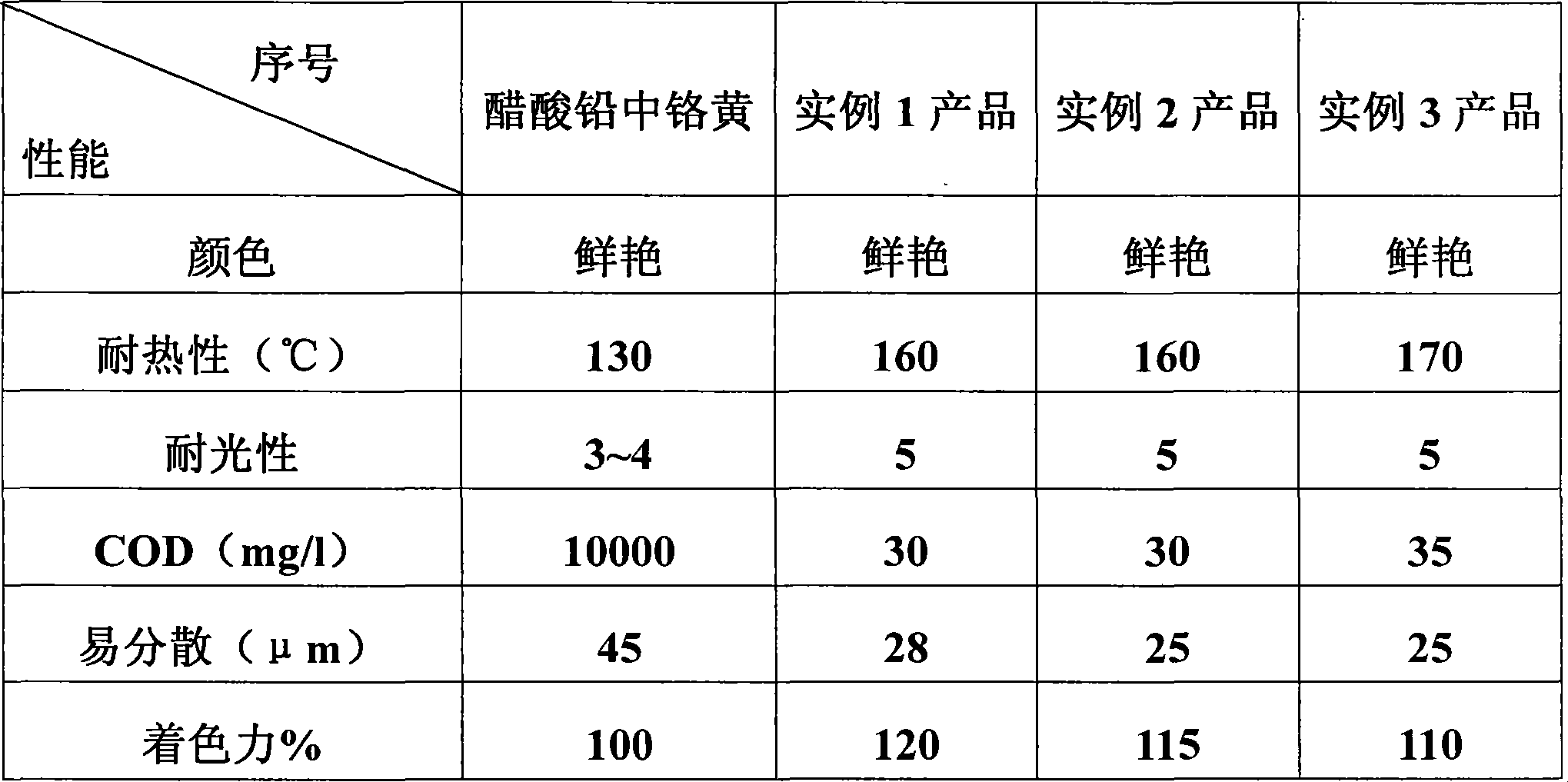

[0022] Add 1256 kg of lead nitrate solution with a concentration of 28% in the reaction tank, dilute it to 4000 L with water, start stirring, control the temperature at 20°C, and keep the pressure at normal pressure, and add sodium dichromate with a concentration of 60% in another batching tank 250 kg, 134 kg of 30% sodium hydroxide, 267 kg of 10% sodium carbonate, 3 kg of sodium hypochlorite, dilute with water to 1000L, add 2 / 3 of the diluted mixture into the reaction barrel, stir for about 20 minutes, and then Add the remaining third of the mixture and stir for about 10 minutes. Dilute 7 kg of sodium silicate to 40 L with water, slowly add it to the reaction tank, dilute 0.6 kg of sulfuric acid with a concentration of 90% to 40 L, add it to the reaction tank, stir for 30 minutes, add 44 kg of aluminum sulfate with a concentration of 50%, 140 kg of soda ash with a concentration of 10% was stirred for 20 minutes, and the pH at the end point was controlled at 7.0 to obtain a me...

Embodiment 2

[0024] Add 1,200 kg of 30% lead nitrate solution to the reaction tank, dilute it to 4,000 L with water, start stirring, control the temperature at 30°C, and keep the pressure at normal pressure, and add 55% sodium dichromate to another batching tank 282 kg, 175 kg of 25% sodium hydroxide, 148 kg of 15% sodium carbonate, and 5 kg of potassium permanganate were diluted with water to 1000 L, and two-thirds of the diluted mixed solution was added to the reaction tank, and stirred for 20 After about 10 minutes, add the remaining third of the mixture and stir for about 10 minutes. Dilute 9 kg of sodium silicate to 50 L with water, slowly add it to the reaction tank, dilute 0.9 kg of sulfuric acid with a concentration of 93% to 40 L, add it to the reaction tank, stir for 30 minutes, add 58 kg of aluminum sulfate with a concentration of 45%, 107 kg of sodium carbonate with a concentration of 15% was stirred for 20 minutes, and the pH at the end point was controlled at 7.2 to obtain a ...

Embodiment 3

[0026] Add 1051 kg of lead nitrate solution with a concentration of 35% in the reaction tank, dilute it with water to 4000L, start stirring, control the temperature at 40°C, and keep the pressure at normal pressure, and add sodium dichromate with a concentration of 45% in another batching tank 356 kg, 204 kg of 20% sodium hydroxide, 200 kg of 20% sodium carbonate, and 8 kg of hydrogen peroxide are diluted with water to 1000 L, and two-thirds of the diluted mixture is added to the reaction tank, and stirred for about 20 minutes. Add the remaining third of the mixture and stir for about 10 minutes. Dilute 13 kg of sodium silicate to 60 L with water, slowly add it to the reaction tank, dilute 1.1 kg of sulfuric acid with a concentration of 96% to 50 L, add it to the reaction tank, stir for 30 minutes, add 70 kg of aluminum sulfate with a concentration of 40%, 95 kg of sodium carbonate with a concentration of 20% was stirred for 20 minutes, and the pH at the end point was controll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance | aaaaa | aaaaa |

| Heat resistance | aaaaa | aaaaa |

| Lightfastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com