Titania mesoporous ball, preparation and use in solar cell

A solar cell and titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of cumbersome process, high cost, and difficult to preserve the pore structure completely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

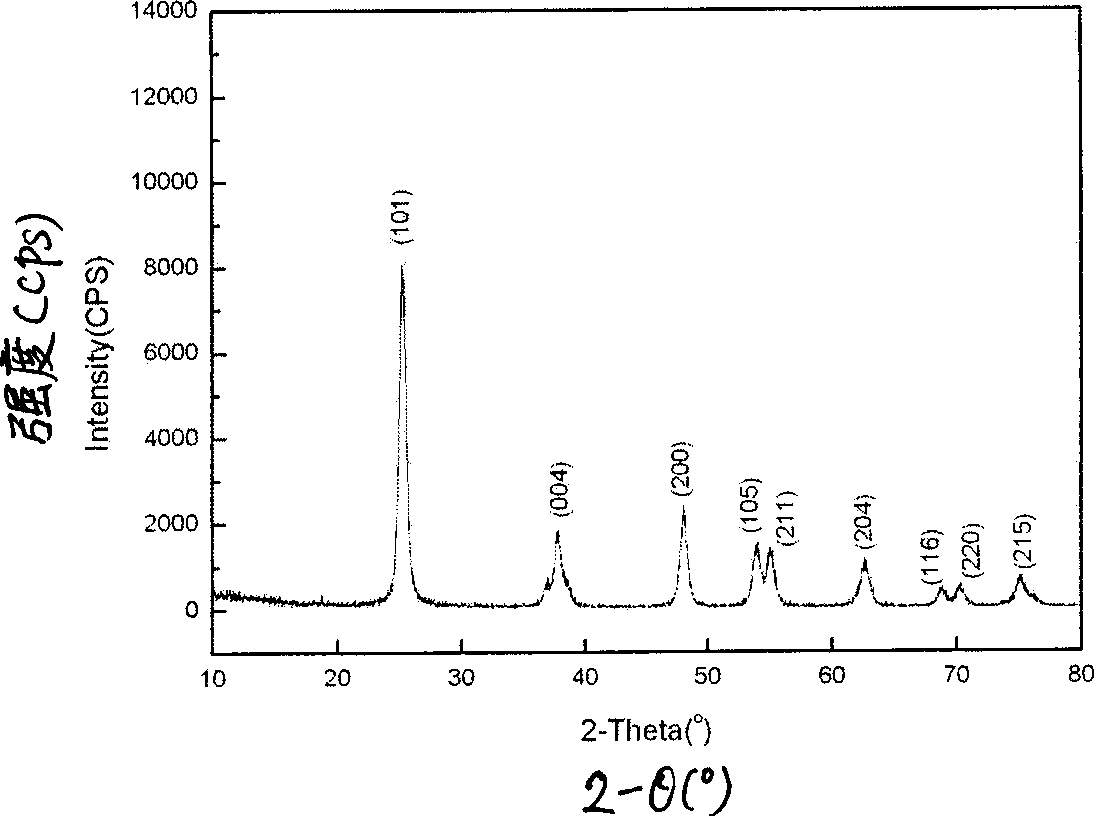

[0017] Dissolve 2.63 g of boric acid in 100 ml of deionized water, dissolve 0.01 mole of n-butyl titanate in 25.5 ml of n-butanol solvent, and slowly add n-butyl titanate in n-butanol dropwise without any stirring In boric acid aqueous solution, after standing still for 48 hours, a white precipitate was obtained. The white precipitate was washed several times with deionized water and absolute ethanol, dried at 60°C, and sintered at 450°C for 3 hours to obtain titanium dioxide mesoporous spheres (such as figure 1 As shown, it is anatase phase, the diameter of mesoporous spheres is 50-200nm, and the specific surface area is 138m 2 / g, average pore diameter 9.5nm). Put 2.40 grams of P25 nano-titanium oxide in a mortar, add 0.8 milliliters of ethanol solution with a volume ratio of 10% acetylacetone, grind for 0.5 hours, add 3.2 milliliters of deionized water and 0.04 milliliters of Triton-100, and continue milling for 0.5 hours to form Sol. The sol was printed on conductive gl...

Embodiment 2

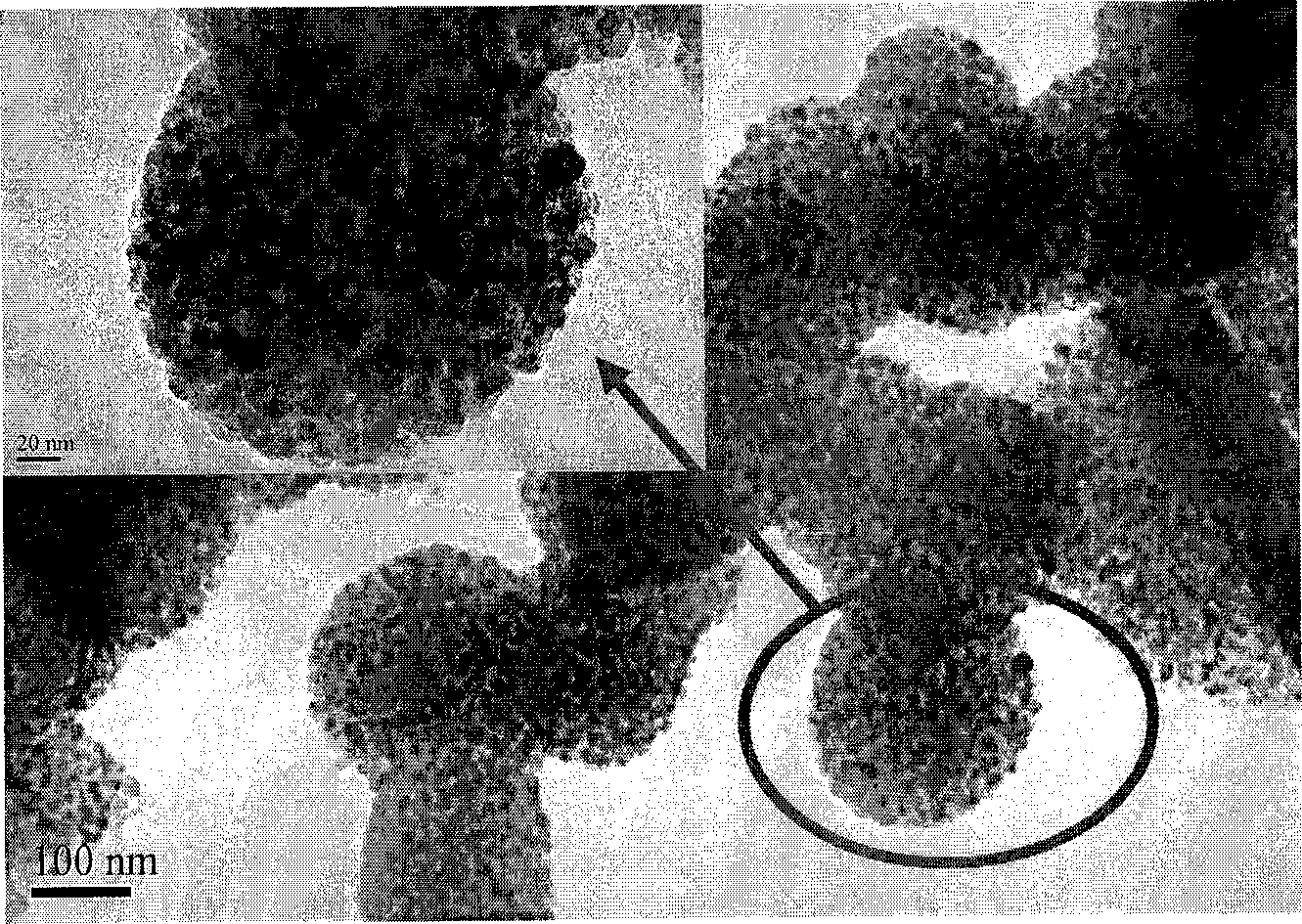

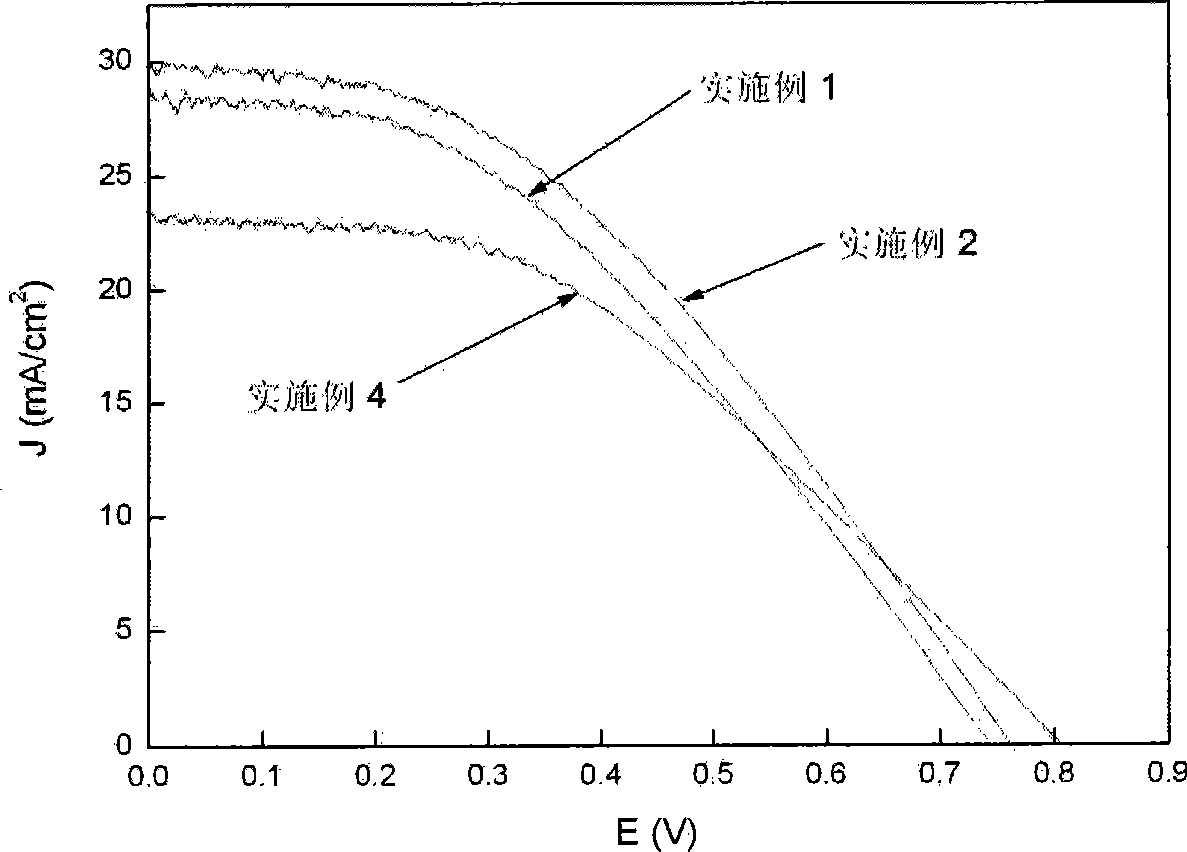

[0019] The steps are the same as in Example 1, except that the quality of the boric acid is 5.26 grams, and the standing time becomes 60 hours. After the white precipitate is dried, it is sintered at 400° C. for 4 hours to obtain titanium dioxide mesoporous spheres (such as figure 2 As shown, the anatase phase, mesoporous sphere diameter 100 ~ 200nm, specific surface area 153m 2 / g, average pore diameter 8.3nm); the composite film was dried under natural conditions for 24 hours, and heat-treated at 450°C for 40 minutes. The photoelectric conversion efficiency of the obtained solar cell device is (9% ± 0.5%), such as image 3 shown.

Embodiment 3

[0021] The steps are the same as in Example 1, except that the mass of boric acid is 5.26 grams, 0.01 mole of n-butyl titanate is dissolved in 25.5 milliliters of cyclohexanol, and the standing time is 24 hours. The white precipitate is dried at 80° C. Sintering at ℃ for 5 hours to obtain titanium dioxide mesoporous spheres (anatase phase, mesoporous sphere diameter 150-300nm, specific surface area 178m 2 / g, average pore size 6.7nm); 1.00 gram of P25 nano-titanium oxide was placed in a mortar, 0.3 milliliters of acetylacetone in ethanol was added, and 1.0 milliliters of deionized water and 0.01 milliliters of Triton-100 were added after grinding for 0.5 hours. The film was prepared by printing the sol on conductive glass by spin coating method, and heat-treated at 500°C for 0.25 hours; the composite film was dried under natural conditions for 48 hours, and heat-treated at 400°C for 2 hours. The concentration of dye solution is 8×10 -4 mol / L, soaking time is 24 hours. The ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com