Preparation of ultra-hydrophobic polyvinylidene fluoride membrane and product thereof

A super-hydrophobic and product technology, applied in the field of preparation of super-hydrophobic polyvinylidene fluoride film, can solve the problems of easy agglomeration of nanoparticles and reduced light transmittance of PVDF film, and achieve low adhesion, good self-cleaning function, good The effect of superhydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The superhydrophobic PVDF membrane preparation method (abbreviation preparation method) of the present invention design comprises following process:

[0020] 1. Preparation of PVDF membrane: PVDF is a high molecular weight semi-crystalline organic fluoropolymer with a crystallinity of 60-80%, and can form microcrystals under certain circumstances. Dissolve PVDF powder in an appropriate solvent such as acetone, DMF or DMAC, and prepare a PVDF solution with a mass fraction of 5-10%, stir at a constant temperature of 60-80°C for 1-2h, let it stand for defoaming for 30-60min, and coat the film. Then dry it at 90-180°C to make a PVDF membrane.

[0021] 2. Plasma treatment of PVDF membrane: Under the condition of vacuum degree of 8-11Pa, the surface of the obtained PVDF membrane is treated with plasma in a specific atmosphere for 5-15min, and the processing power is 100-200W, so that active groups are generated on the surface of the membrane; the specific The atmosphere is n...

Embodiment 1

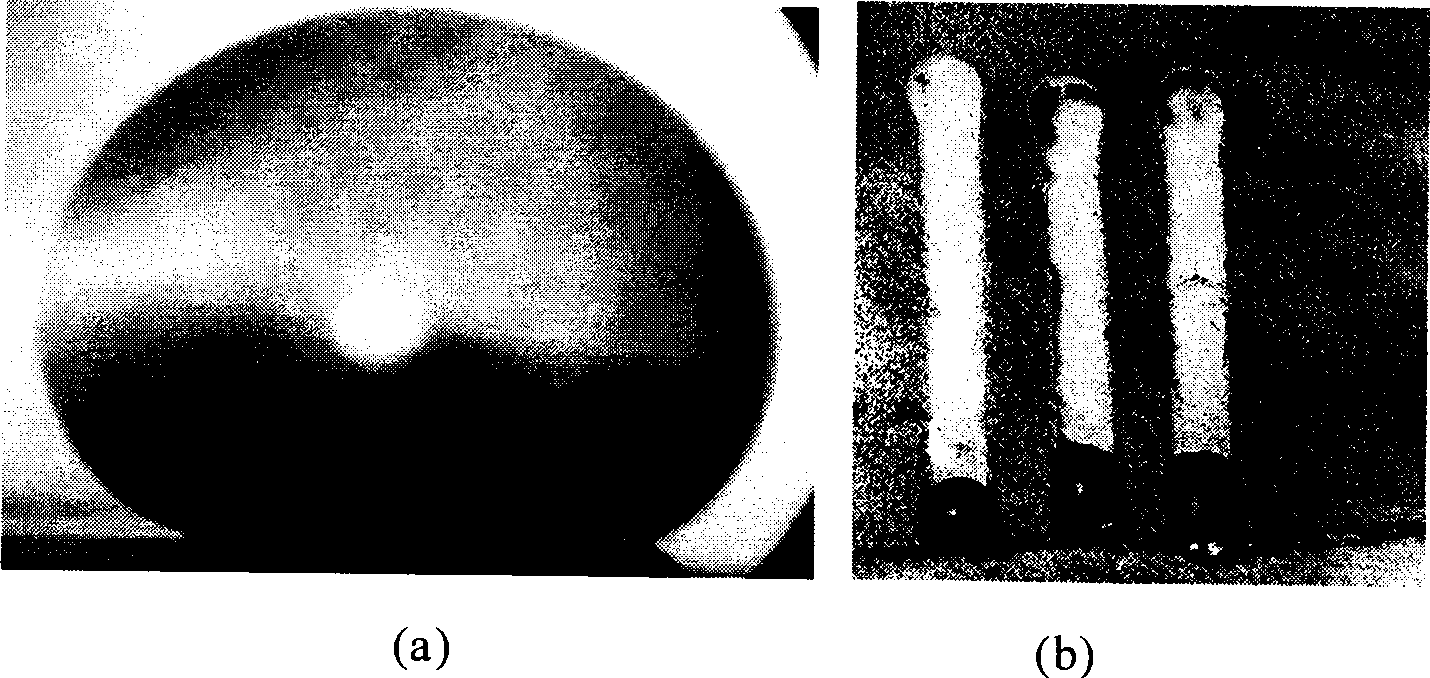

[0027] 1. Preparation of PVDF film: Dissolve PVDF powder in DMF solution, prepare a PVDF solution with a mass fraction of 5%, stir at 60°C for 2 hours, let it stand for defoaming for 30 minutes, coat the film, and dry it at 120°C to obtain a film with Microstructured PVDF membrane.

[0028] 2. Plasma treatment of PVDF membrane: Under the condition of vacuum degree of 10Pa, the surface of PVDF membrane was treated with oxygen microwave plasma for 5 minutes, and the processing power was 200W, so that active groups were generated on the surface of the membrane.

[0029] 3. Chemical bath deposition method to modify the plasma-treated PVDF membrane: first dissolve methyltrichlorosilane in toluene solvent to make a methyltrichlorosilane solution with a volume concentration of 1 / 10, and place it in a relative humidity 60% airtight container, stand-by, then immerse the PVDF film that has been treated by plasma in the methyltrichlorosilane solution in the airtight container, carry out ...

Embodiment 2

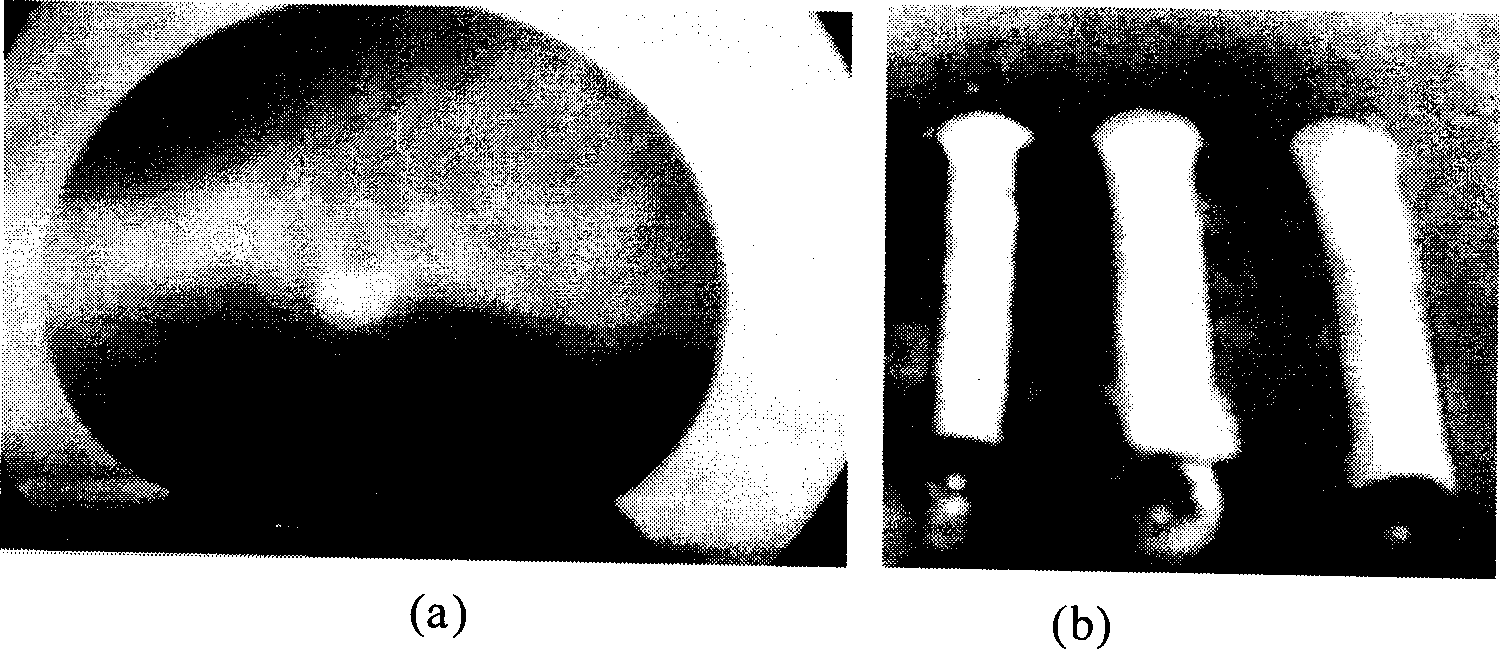

[0032] 1. Preparation of PVDF film: Dissolve PVDF powder in acetone solution, prepare a PVDF solution with a mass fraction of 10%, stir at a constant temperature of 80°C for 1h, let it stand for defoaming for 50min, coat the film, and dry it at 100°C to obtain a film with Microstructured PVDF membrane.

[0033] 2. Plasma treatment of PVDF membrane: Under the condition of vacuum degree of 10Pa, the surface of PVDF membrane was treated with oxygen glow plasma for 12min, and the processing power was 200W to generate active groups on the surface of the membrane.

[0034] 3. Use chemical vapor deposition to modify the plasma-treated PVDF membrane: first dissolve methyltrichlorosilane in toluene solvent to make a solution of methyltrichlorosilane with a volume concentration of 1 / 10, and place it in a relatively Humidity 30% airtight container, stand-by; Put the PVDF film that has been treated with oxygen plasma on the methyltrichlorosilane solution in the airtight container, after r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com