Enzyme composition and use thereof in beer brewing

A technology of enzyme composition and beer, which is applied in the field of bioengineering to achieve the effects of improving leaching rate and filtration speed, reducing protein content and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

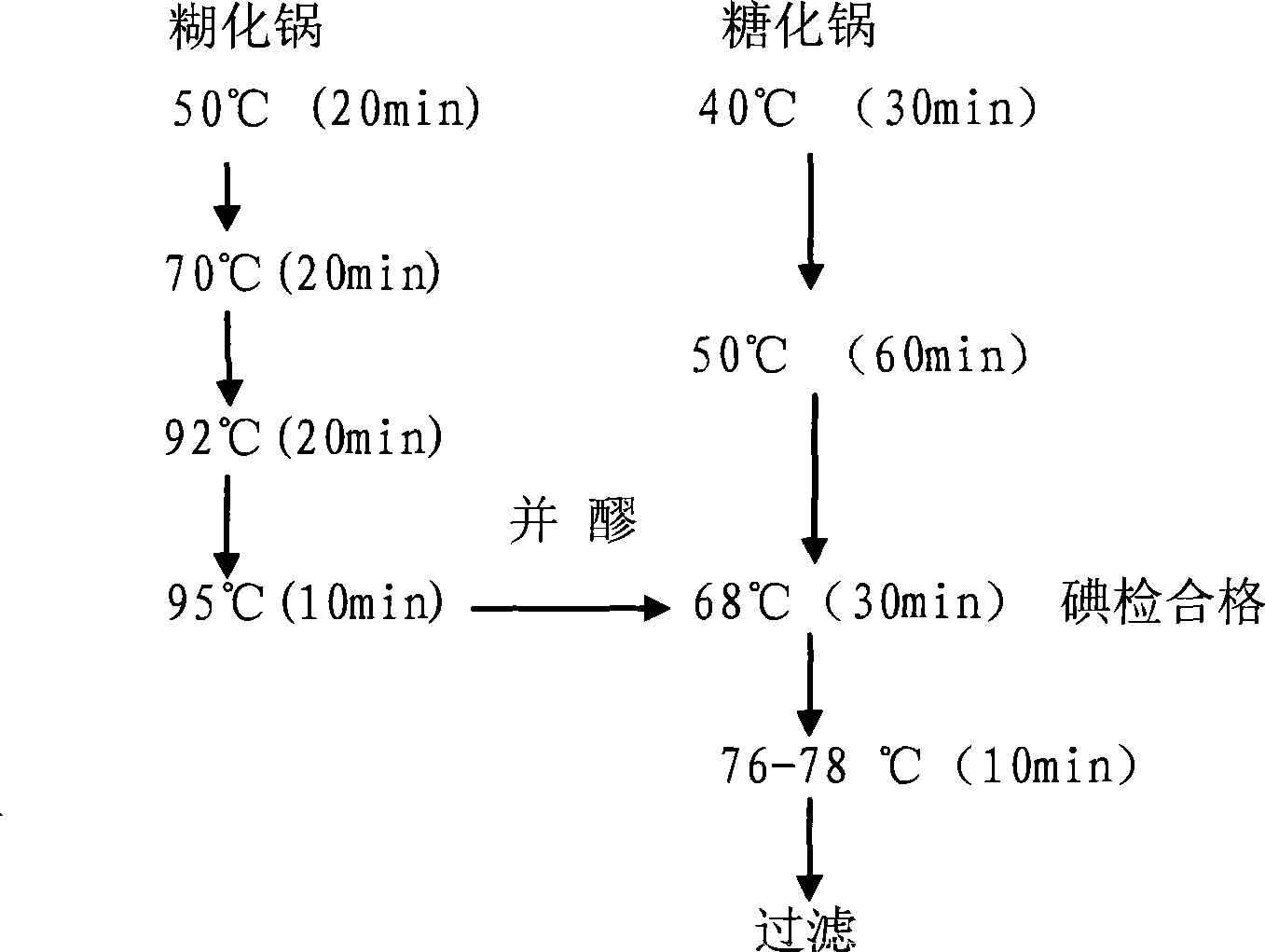

Method used

Image

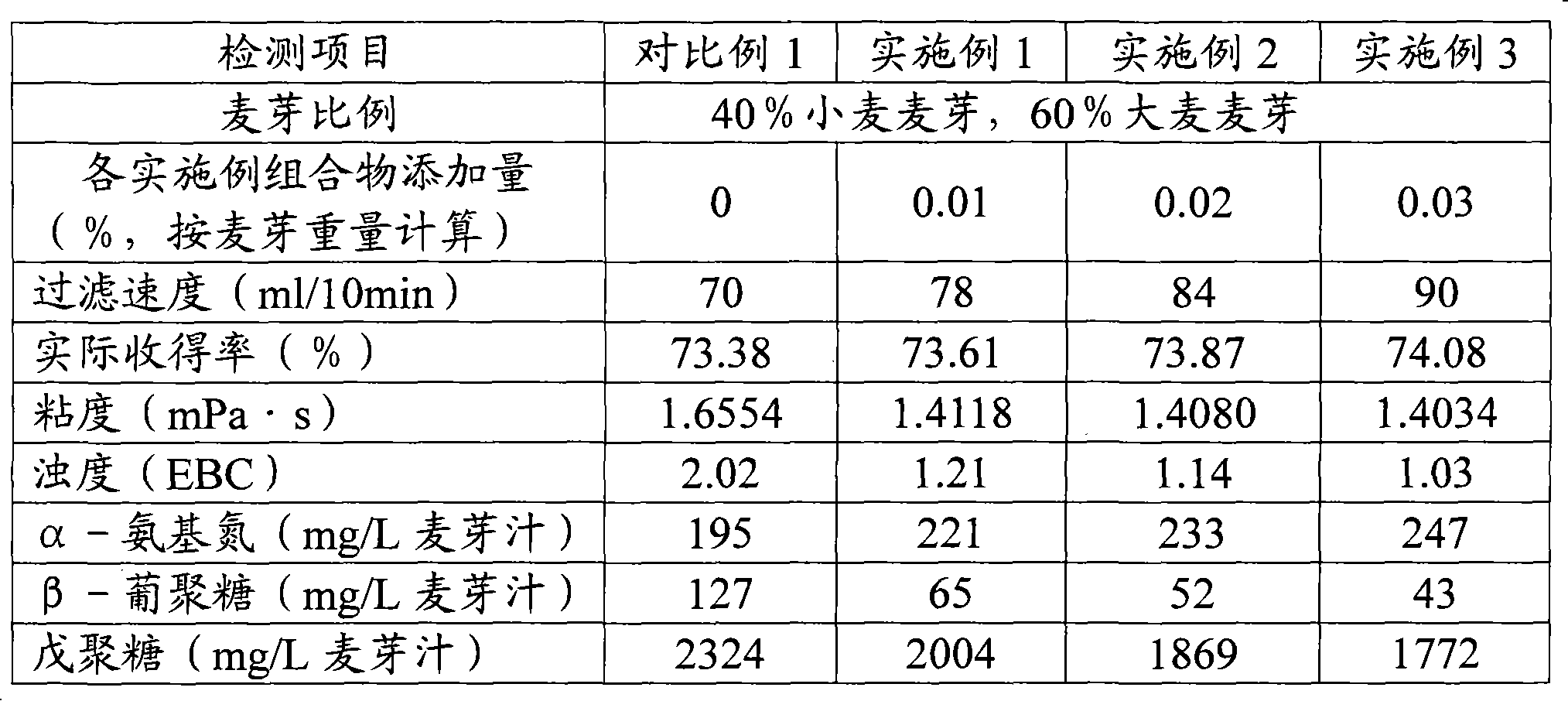

Examples

Embodiment 1

[0020] The weight percent of each component of the enzyme composition is: 11% of amylase, 55% of protease, 18% of beta-glucanase, 9% of xylanase and 7% of corn starch.

[0021] The preparation method: the raw material enzymes are sieved respectively, and then put into an automatic mixing tank for compounding according to the proportion, and then packaged to become a product.

Embodiment 2

[0023] The weight percentage of each component of the preparation enzyme composition is: 4% of amylase, 33% of protease, 13% of beta-glucanase, 3% of xylanase and 47% of corn starch.

[0024] The preparation method is the same as in Example 1.

Embodiment 3

[0026] The weight percentage of each component of the preparation enzyme composition is: 9% of amylase, 50% of protease, 16% of beta-glucanase, 6% of xylanase and 19% of corn starch.

[0027] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com