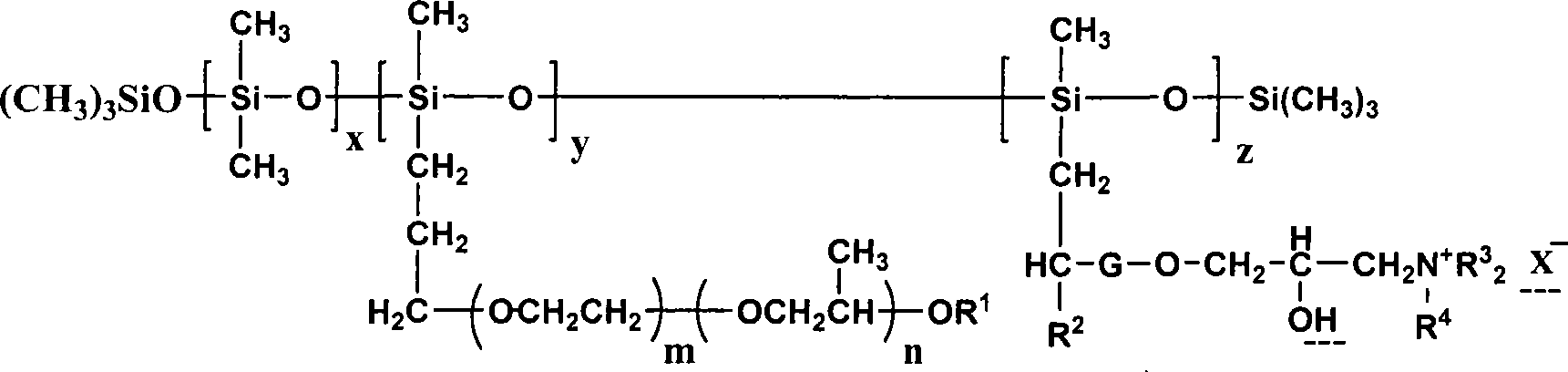

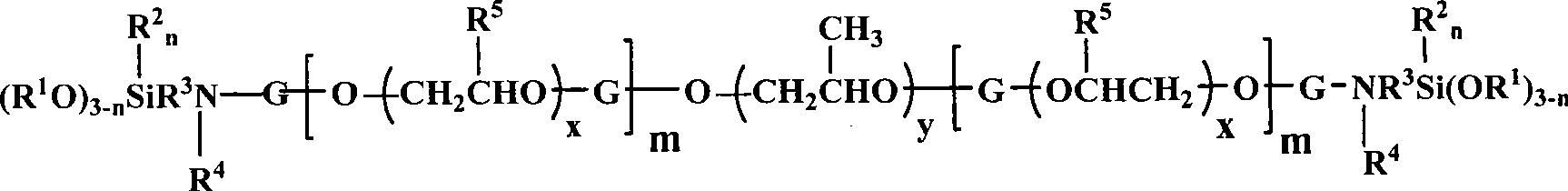

Quaternary ammonium salt type polyether-polysiloxane non-ionic cation surface active agent and active organosilicon end capping polypropylene oxide cationoid emulsion

A surfactant and polysiloxane technology, applied in the directions of dissolution, other chemical processes, chemical instruments and methods, etc., can solve the problems of difficulty in water-based, no reports of SPPO water-based, etc., and achieve strong surface activity. , the effect of high yield and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] (1) Preparation of quaternary ammonium salt type polyether-polysiloxane nonionic cationic surfactant

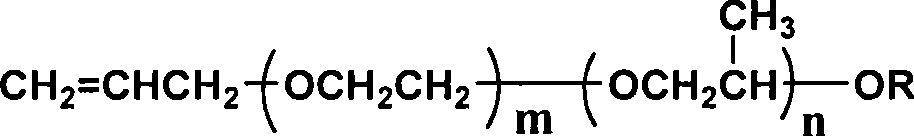

[0072] Add 4.5g PDMHS (chemically pure, Hwt%=0.44, Mn=1950, Si-H: 0.02mol) and 6.6g allyl-terminated polyether (0.01mol, Mn=660, its schematic general In the formula: m=12, n=0, and R is OCCH 3 ), stirring and mixing evenly, the temperature was raised to 90° C., and after 10 minutes of feeding nitrogen, adding 0.08 milliliters of concentration was a [Pt] catalyst (isopropanol solution of chloroplatinic acid hexahydrate) of 2 wt %, and reacted at constant temperature for 5 hours; 1.26g AGE (0.012mol, analytically pure), continue the constant temperature reaction for 6 hours, and then evaporate the solvent and excess AGE under reduced pressure to obtain epoxy-containing polyether-polysiloxane.

[0073] Dissolve the above product in 20ml of ethanol, heat up to 55°C, add 1.83g of diethylamine (0.025mol, analytically pure), react for 6 hours, evaporate the solvent and exce...

Embodiment 2

[0078] (1) Preparation of quaternary ammonium salt type polyether-polysiloxane nonionic cationic surfactant

[0079] Add 5.3g PDMHS (chemically pure, Hwt%=0.38, Mn=2100, Si-H: 0.02mol) and 6.6g allyl-terminated polyether (0.01mol, Mn=660, which shows In the general formula: m=12, n=0, and R is OCCH 3 ), stir and mix evenly, heat up to 80°C, add 0.08 ml concentration of [Pt] catalyst (1,1,2,2-tetramethyl-1,2-divinyldi Siloxane solution), after constant temperature reaction for 5 hours, add 1.37gAGE (0.013mol, analytically pure), after continuing constant temperature reaction for 7 hours, decompress to remove solvent and excess AGE, obtain epoxy group-containing polyether-polysiloxane alkyl.

[0080] Dissolve the product in 25ml of ethanol, heat up to 55°C, add 1.32g of dimethylamine (0.03mol, analytically pure), react for 6 hours, evaporate the solvent and excess dimethylamine under reduced pressure; dissolve the resulting product in 30ml Ethanol, the temperature of the wate...

Embodiment 3

[0085] (1) Preparation of quaternary ammonium salt type polyether-polysiloxane nonionic cationic surfactant

[0086] 6.1g PDMHS (chemically pure, Hwt%=0.33, Mn=1800, Si-H: 0.02mol) and 12g allyl-terminated polyether (0.01mol, Mn=1200, in its schematic general formula: m= 20, n=4, and R is CH 3 ) Stir and mix evenly, heat up to 90°C, feed nitrogen for 10 minutes, add 0.08 milliliters of concentration as 2wt% [Pt] catalyst (isopropanol solution of potassium chloroplatinate), constant temperature reaction for 6 hours; add 1.37g AGE (0.013mol, analytically pure), after continuing the constant temperature reaction for 6 hours, the excess AGE was evaporated under reduced pressure to obtain epoxy-containing polyether-polysiloxane.

[0087] Dissolve the above product in 25ml of methanol, heat up to 55°C, add 2.19g of diethylamine (0.03mol, analytically pure) to react for 6 hours, then distill off the solvent and excess diethylamine under reduced pressure; dissolve the obtained produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com