Method for removing nickel and vanadium in hydrocarbon raw material

A hydrocarbon raw material and nickel removal technology, which is applied in the fields of refined hydrocarbon oil, petroleum industry, and through electric/magnetic refining, etc., can solve the problem that the consumption of nickel and vanadium agent is small, the consumption of nickel and vanadium agent is large, and it cannot meet the requirements of industrial application and other issues to achieve the effect of reducing costs and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

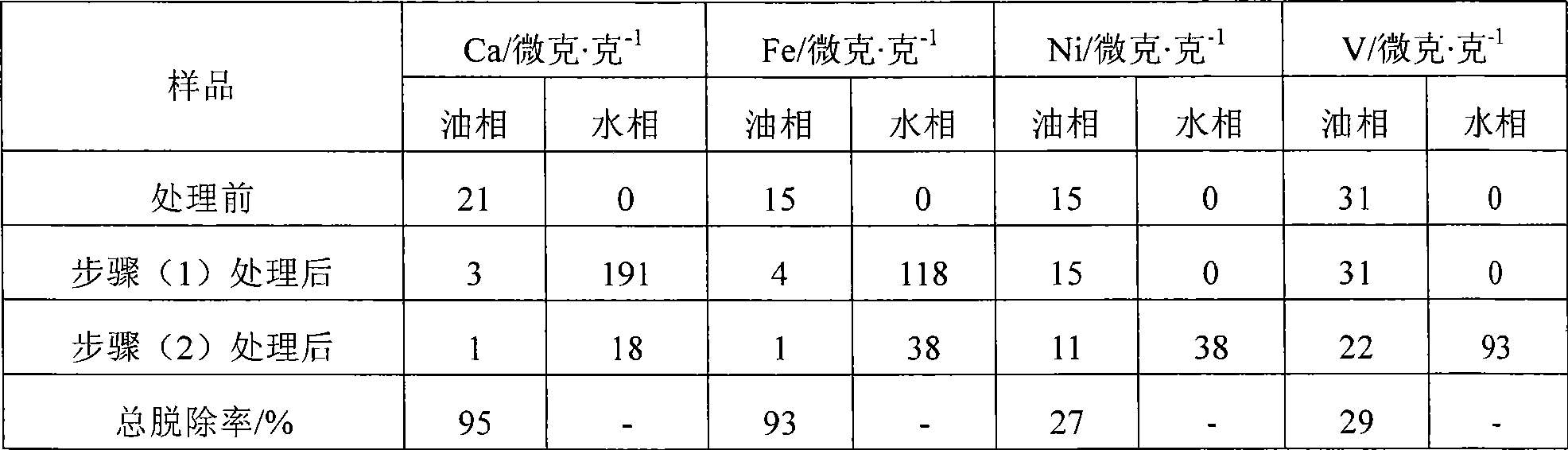

[0031] This example is used to illustrate the method for removing nickel and vanadium in hydrocarbon raw materials provided by the present invention.

[0032] Hydrocarbon feedstock: crude oil.

[0033] Aqueous solution of demulsifier: aqueous solution of polyethylene glycol ether with a concentration of 1% by weight.

[0034] Aqueous solution of desalting agent: an aqueous solution of a composite desalting agent with a concentration of 0.5% by weight, and the composite desalting agent is composed of 70% by weight of acetic acid, 20% by weight of tartaric acid and 10% by weight of EDTA.

[0035] Aqueous solution of nickel and vanadium removal agent: a methanesulfonic acid aqueous solution with a concentration of 20% by weight.

[0036] (1) Mix 100 grams of crude oil (see Table 1 for metal content), 10 grams of desalting agent and 0.2 gram of demulsifier in a sealed mixer at 95 ° C for 1 minute, and then transfer them all to a sealed electric The first-level electric desalinat...

Embodiment 2

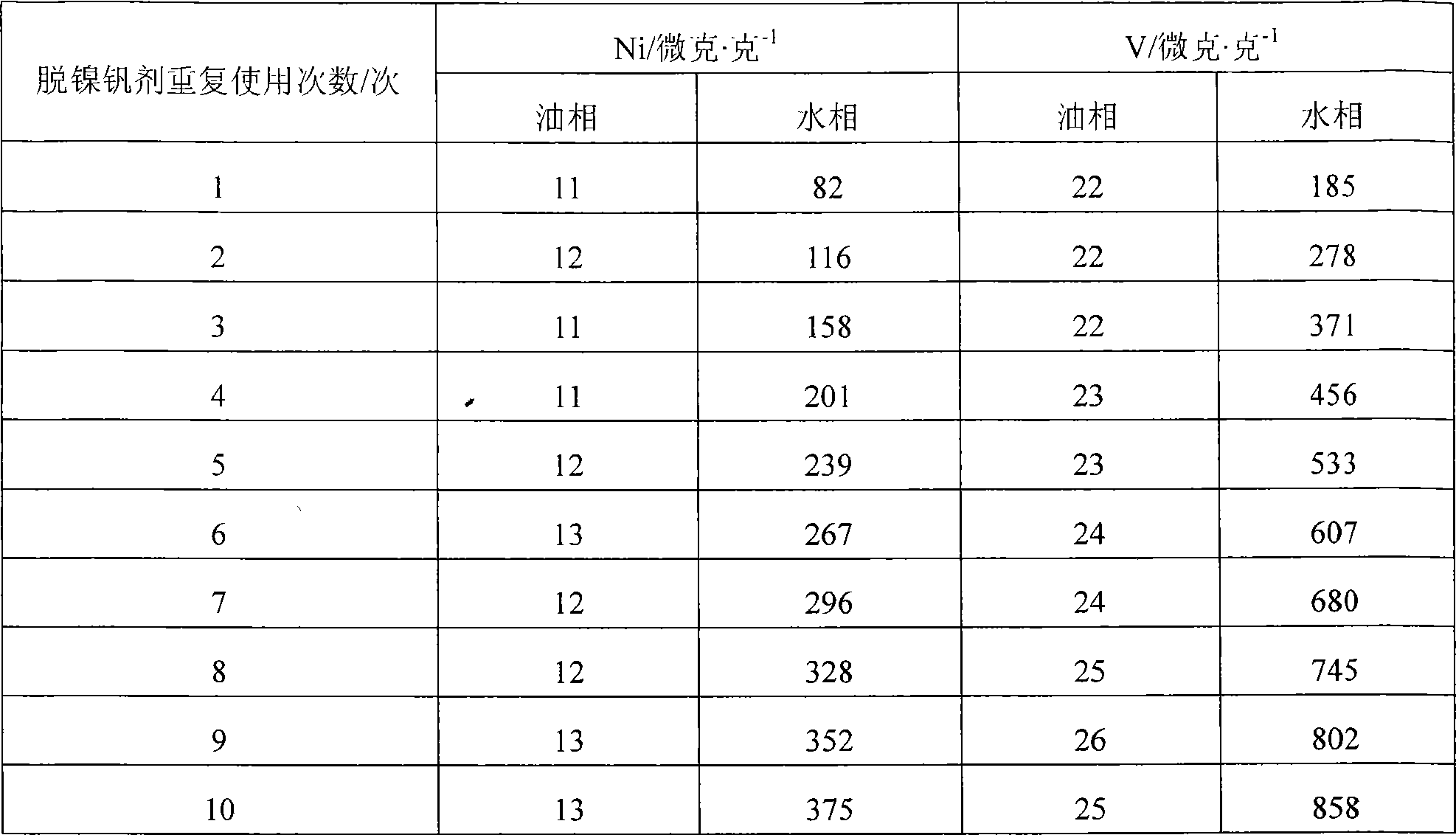

[0045] This example is used to illustrate the method for removing nickel and vanadium in hydrocarbon raw materials provided by the present invention.

[0046] Nickel and vanadium in the hydrocarbon feedstock were removed according to the method described in Example 1, except that the aqueous solution of the nickel and vanadium removal agent used was a HEDP aqueous solution with a concentration of 20% by weight. The experimental results are shown in Table 3 and Table 4 respectively.

[0047] table 3

[0048]

[0049] Table 4

[0050]

[0051] According to the results of Tables 3 and 4, it can be seen that the total concentration of nickel and vanadium in the aqueous solution separated by step (2) after recycling for 10 times reaches 1549 micrograms / gram, which is lower than 2000 micrograms / gram. Due to the low content of nickel and vanadium in the hydrocarbon feedstock, the consumption of the nickel-removing vanadium agent is small, and the initial amount of the nickel-...

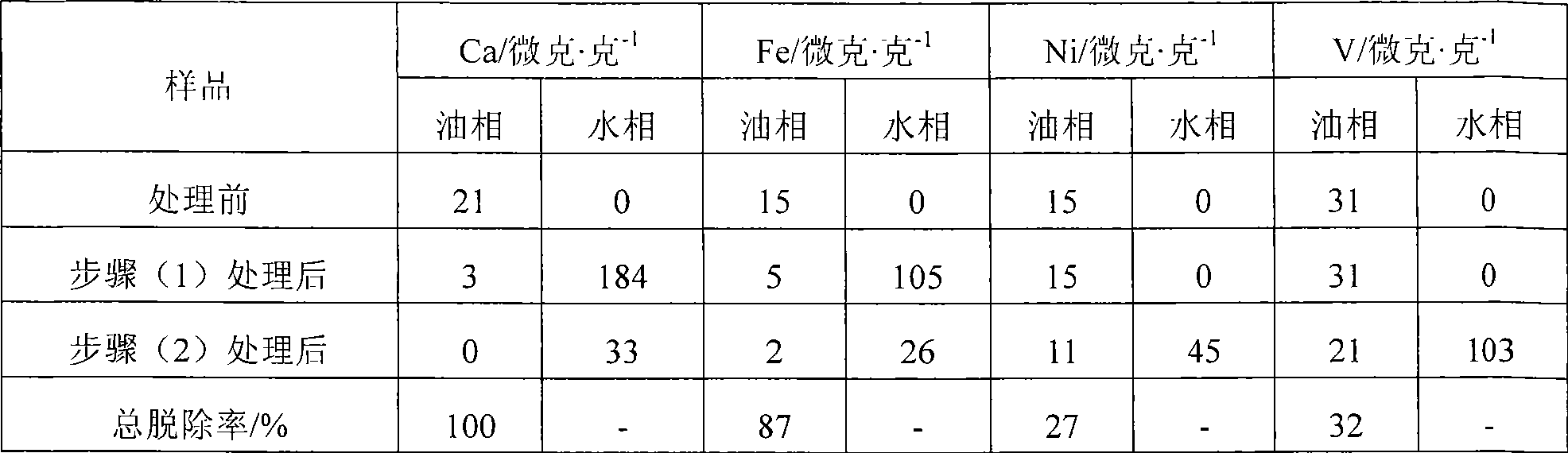

Embodiment 3

[0053] This example is used to illustrate the method for removing nickel and vanadium in hydrocarbon raw materials provided by the present invention.

[0054] According to the method described in Example 1, nickel and vanadium in the hydrocarbon feedstock are removed, and the difference is that the hydrocarbon feedstock is a vacuum residue; the aqueous solution of the demulsifier has a concentration of 1% by weight. ) aqueous solution; the aqueous solution of the desalting agent is an aqueous solution of a composite desalting agent with a concentration of 2% by weight, and the composite desalting agent is composed of 30% by weight of citric acid and 70% by weight of acetic acid; The aqueous solution is an aqueous solution of trichloroacetic acid with a concentration of 30% by weight; see Table 5 and Table 6 for the analysis results of the metal content of the two-phase oil and water.

[0055] table 5

[0056]

[0057] Table 6

[0058]

[0059] According to the results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com