Protein collection and enzymolysis integrated sample pretreatment apparatus and its production

A sample pretreatment and protein technology, applied in the preparation of test samples, etc., can solve the problems of only suitable enzyme column reactors, difficulty in matching flow rates, and decreased activity, and achieve low cost, fast enzymatic hydrolysis, and simple production methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

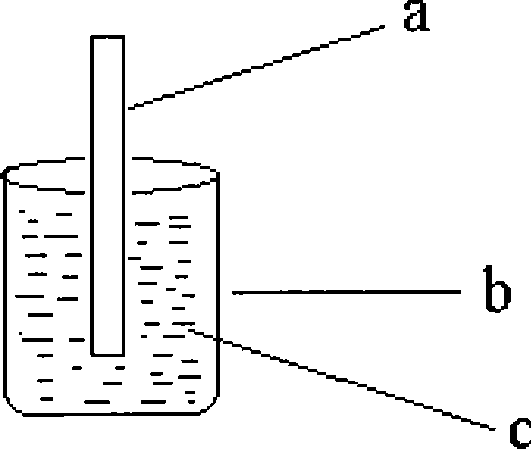

[0023] Fabrication of a sample pretreatment device integrating protein collection and rapid enzymatic hydrolysis

[0024] 1) Fabrication of the reaction device: Drill a hole on the cap of the centrifuge tube (C), the diameter of which is equivalent to that of the solid tube a.

[0025] 2) Preparation of matrix: using glycidyl methacrylate as a monomer and ethylidene dimethacrylate as a crosslinking agent to prepare a porous monolithic matrix. Weigh 0.6g of glycidyl methacrylate (GMA), 0.4g of ethylidene dimethacrylate (EDMA), dissolve in 1g of cyclohexanol / dodecanol (mass ratio: 50 / 50) mixed solvent, ultrasonically After 10 minutes, wrap the centrifuge tube containing the reaction solution with aluminum foil. Quickly weigh 1mg of photoinitiator DMPA and shake for 30s. Such as figure 1 As shown, take 0.8mL of the reaction solution c into the reactor b, insert the solid tube a, and put it into the ultraviolet crosslinking apparatus for photopolymerization for 10 minutes.

[...

Embodiment 2

[0031] 1) Fabrication of the reaction device: Drill a hole on the cap of the centrifuge tube (C), the diameter of which is equivalent to that of the solid tube a.

[0032] 2) Preparation of matrix: using glycidyl methacrylate as a monomer and ethylidene dimethacrylate as a crosslinking agent to prepare a porous monolithic matrix. Weigh 0.6g of glycidyl methacrylate (GMA), 0.4g of ethylidene dimethacrylate (EDMA), dissolve in 1g of cyclohexanol / dodecanol (mass ratio: 50 / 50) mixed solvent, ultrasonically After 10 minutes, wrap the centrifuge tube containing the reaction solution with aluminum foil. Quickly weigh 1mg of photoinitiator DMPA and shake for 30s. Such as figure 1 As shown, take 0.8mL of the reaction solution c into the reactor b, insert the solid tube a, and put it into the ultraviolet crosslinking apparatus for photopolymerization for 10 minutes.

[0033] 3) After taking out the solid tube a, add methanol and soak in the reaction device for 4 hours, then add 29% a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com