Preparation method of phosphorylated peptidoglycan

A technology for phosphorylating peptidoglycan and peptidoglycan, which can be applied in biochemical equipment and methods, microorganism-based methods, microorganisms, etc. , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

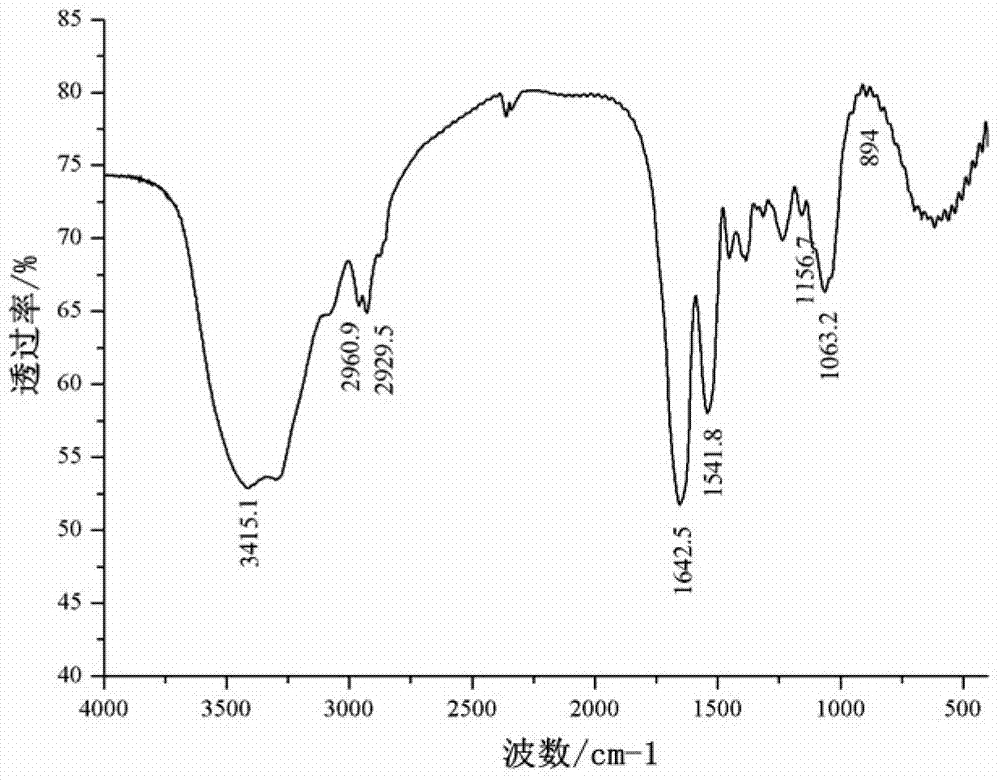

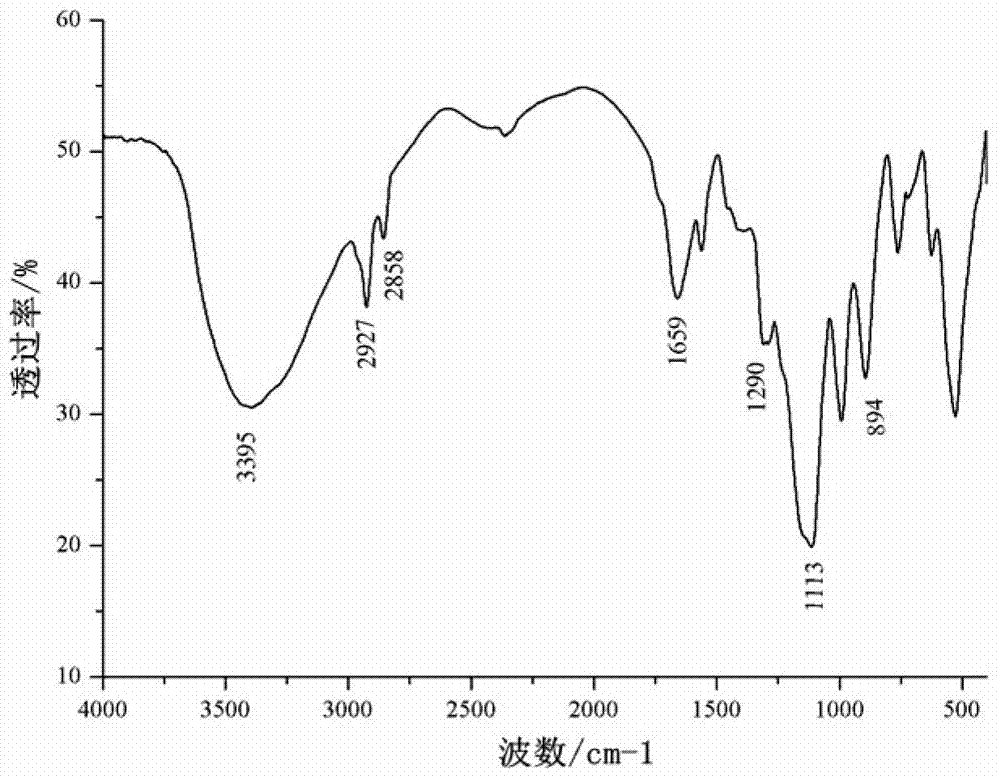

Method used

Image

Examples

Embodiment 1

[0036] The invention uses common commercially available Lactobacillus acidophilus bacteria powder as a raw material to extract the peptidoglycan. First, inoculate 2 mg of bacterial powder into 200 mL of MRS liquid medium, and culture it statically at 37°C for 24 hours to activate the strain. A method for preparing phosphorylated peptidoglycan of the present invention specifically includes the following steps:

[0037] (1) Preparation of peptidoglycan

[0038] a. Bacteria collection: Inoculate the activated Lactobacillus acidophilus into the MRS liquid medium with an inoculum volume of 4% by volume, culture it in a constant temperature incubator at 38.5°C for 20 hours, centrifuge at 6500r / min for 15min to collect the bacteria, and use distilled water repeatedly Wash until the cells are milky white; the preparation method of the MRS liquid medium is as follows: 10g of peptone, 10g of beef extract, 5g of yeast extract, 10g of glucose, 2g of triamine citrate, 2g of dipotassi...

Embodiment 2

[0047] With embodiment 1, its difference is:

[0048] (1) Preparation of peptidoglycan

[0049] Inoculate the activated Lactobacillus acidophilus into the MRS liquid medium with an inoculation amount of 3% by volume, and culture it in a constant temperature incubator at 37°C for 16 hours, then centrifuge at 5000r / min for 20 minutes to collect the bacteria, and wash them repeatedly with distilled water until the bacteria are milky white ;Suspend the bacteria in 40% hydrofluoric acid solution at a solid-to-liquid ratio of 1g:9ml, place overnight at 4°C, centrifuge at 7000 r / min for 20min to collect cell wall precipitates without teichoic acid, and wash the precipitates with distilled water To neutrality; dissolve the precipitate in chymotrypsin phosphate buffer according to the solid-liquid ratio of 2g:5ml, shake at 110r / min on a shaker at 37°C for 17h, inactivate in a boiling water bath for 4min, and centrifuge at a speed of 1500r / min for 6min. Discard the undissolved pr...

Embodiment 3

[0055] With embodiment 1, its difference is:

[0056] (1) Preparation of peptidoglycan

[0057] Inoculate the activated Lactobacillus acidophilus into the MRS liquid medium with an inoculation amount of 5% by volume, and culture it in a constant temperature incubator at 40°C for 24 hours, then centrifuge at 8000r / min for 10 minutes to collect the bacteria, and wash them repeatedly with distilled water until the bacteria are milky white ;Suspend the bacteria in a 50% hydrofluoric acid solution at a solid-to-liquid ratio of 1g:9ml, place at 4°C overnight, centrifuge at 9000 r / min for 10min to collect the cell wall precipitate, and wash the precipitate with distilled water until neutral; Dissolve in chymotrypsin phosphate buffer at a solid-to-liquid ratio of 2g:5ml, shake on a shaker at 40°C at 130r / min for 15h, inactivate in a boiling water bath for 6min, centrifuge at a speed of 2500r / min for 4min, and put the supernatant at 12000r Centrifuge at 9000r / min for 10min, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com