Nutrient fish meat prepared food for children and technique for preparing the same

A technology for conditioning food and preparation technology, applied in food preparation, food science, application, etc., can solve problems such as anemia, nutrient deficiency, immune function decline, etc., and achieve the effect of optimizing protein composition, high nutritional value, and increasing water holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0044] The following are several specific embodiments of the present invention to further illustrate the present invention, but the present invention is not limited thereto. Example 1: Formula: surimi: 650kg; lean meat: 150kg; egg white: 80kg; drinking water: 50kg, starch: 100kg; soybean protein powder: 35kg; wheat protein powder: 35kg; table salt: 20kg; compound phosphate: 5kg; MSG: 15kg; sesame oil: 10kg; garlic: 10kg; calcium carbonate: 2kg; zinc lactate dihydrate: 30g; ferrous lactate trihydrate: 25g; vitamin A: 10g; vitamin D: 8g.

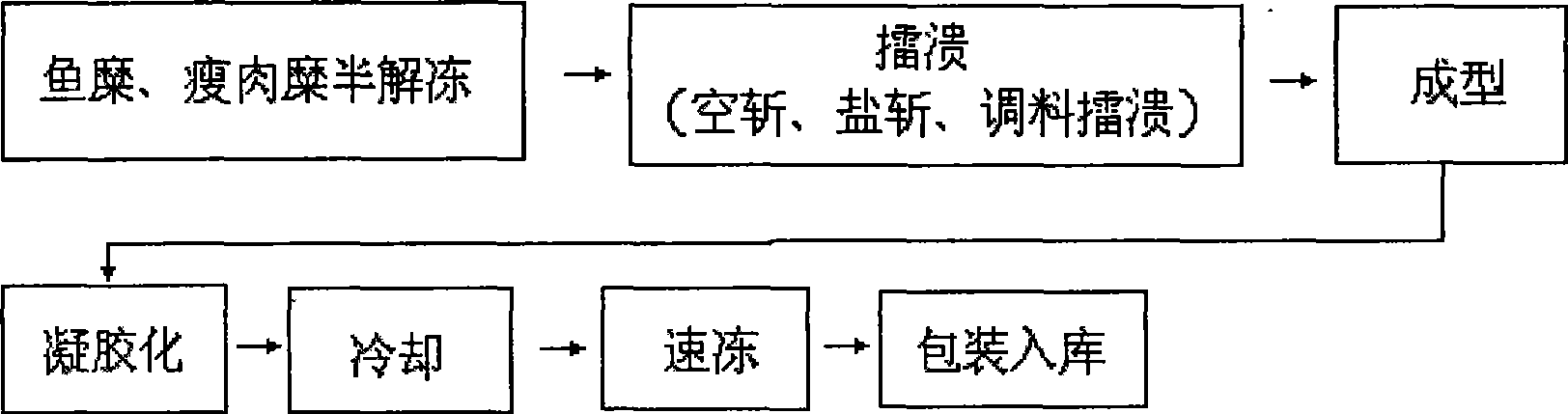

[0045] According to the formula, the specific steps of the preparation process are:

[0046] (1) Half thawing of surimi and lean minced meat: thaw frozen surimi and lean meat at room temperature until the center temperature reaches -5°C and the surface temperature is -1°C;

[0047] (2) Beating: 3 stages of empty grinding, salt grinding and seasoning grinding: empty grinding, salt grinding and seasoning grinding all use vacuum grinding machine...

example 2

[0058] Formula: surimi: 800kg; lean meat: 100kg; egg white: 110kg; drinking water: 70kg, starch: 120kg; soybean protein powder: 45kg; wheat protein powder: 25kg; salt: 25kg; compound phosphate: 5kg; monosodium glutamate: 15kg ; Sesame oil: 10kg; Garlic: 10kg; Calcium carbonate: 3kg; Zinc lactate 2 hydrate: 35g; Ferrous lactate 3 hydrate: 30g; Vitamin A: 15g;

[0059] According to the formula, the specific steps of the preparation process are:

[0060] (1) Half thawing of surimi and lean minced meat: thaw frozen surimi and lean meat at room temperature until the center temperature reaches -5°C and the surface temperature is -1°C;

[0061] (2) Beating: 3 stages of empty grinding, salt grinding and seasoning grinding: empty grinding, salt grinding and seasoning grinding all use vacuum grinding machine and vacuum cutting machine.

[0062] a) Empty beating: put half-thawed surimi into a beating machine for empty beating; the time is controlled at 25 minutes, and the temperature is...

example 3

[0072] Formula: surimi: 550kg; lean meat: 250kg; egg white: 50kg; drinking water: 30kg, starch: 70kg; soybean protein powder: 45kg; wheat protein powder: 40kg; salt: 20kg; compound phosphate: 5kg; monosodium glutamate: 15kg ;Sesame Oil: 15kg; Garlic: 15kg; Calcium Carbonate: 3kg; Zinc Lactate 2 Hydrate: 35g; Ferrous Lactate Trihydrate: 35g; Vitamin A: 15g;

[0073] According to the formula, the specific steps of the preparation process are:

[0074] (1) Semi-thawed surimi and lean minced meat: thaw frozen surimi and lean meat at room temperature until the center temperature reaches -3°C and the surface temperature is 0°C;

[0075] (2) Beating: 3 stages of empty grinding, salt grinding and seasoning grinding: empty grinding, salt grinding and seasoning grinding all use vacuum grinding machine and vacuum cutting machine.

[0076] a) Empty beating: put half-thawed surimi into a beating machine for empty beating; the time is controlled at 25 minutes, and the temperature is at 4°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com