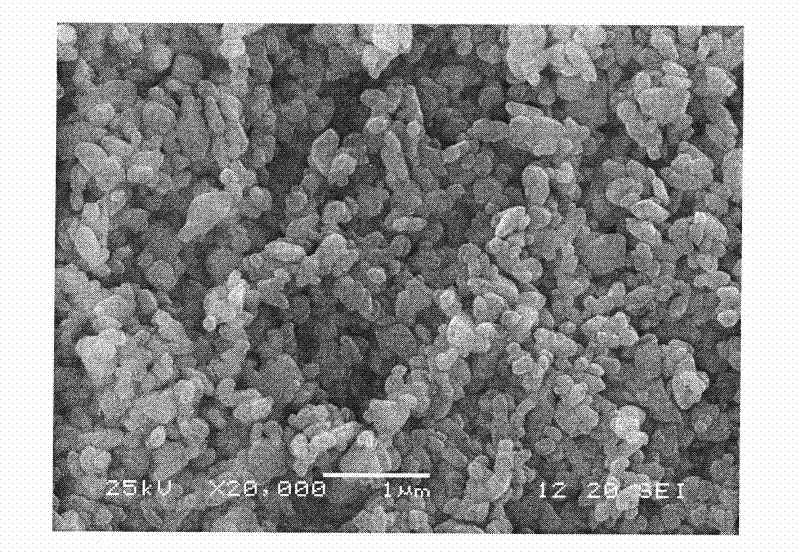

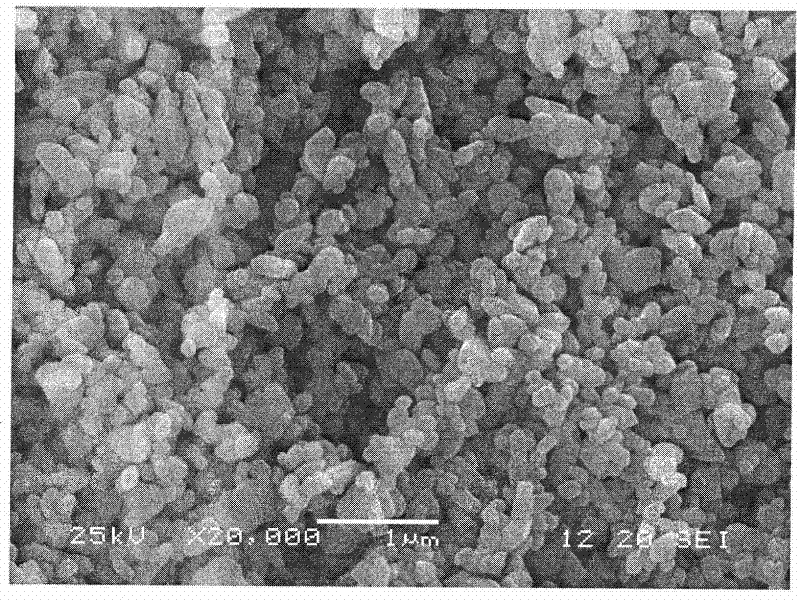

Preparation of subsphaeroidal barium sulfate by sulfuric acid process and use in copper foil substrate

A barium sulfate, nearly spherical technology, applied in chemical instruments and methods, calcium/strontium/barium sulfate, calcium/strontium/barium compounds, etc., can solve problems such as wide particle size distribution and irregular shape of barium sulfate particles , to achieve a wide range of applications, improve the Tg value and flame retardant performance, high thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (a) Grinding and mixing barite and anthracite, putting them into a calcining converter for calcination, the temperature is controlled at 1200° C., and the calcination time is 2 hours to generate crude barium sulfide containing about 60% of barium sulfide;

[0024] (b) Put the above-mentioned crude barium sulfide into the leaching tank and soak it in hot water at 80°C to prepare a solution containing 114g / L barium sulfide, and adjust the temperature to 67°C, mix the barium sulfide solution with excess sulfuric acid (industrial sulfuric acid, 98%) is added in the continuous reactor simultaneously and reacts to generate barium sulfate slurry and hydrogen sulfide, and the adding rate of barium sulfide solution is 4000L / h, and the concentration of sulfuric acid add-on is 2.7g / L according to the concentration of residual sulfuric acid in the barium sulfate slurry after the completion of the reaction calculate;

[0025] (c) Pass hot air into the barium sulfate slurry to disch...

Embodiment 2

[0029] (a) Grinding and mixing barite and anthracite, putting them into a calcining converter for calcination, the temperature is controlled at 1200° C., and the calcination time is 2 hours to generate crude barium sulfide containing about 60% of barium sulfide;

[0030] (b) Put the above-mentioned crude barium sulfide into the leaching tank and soak it in hot water at 80°C to prepare a solution containing 110g / L barium sulfide, and adjust the temperature to 65°C, mix the barium sulfide solution with excess sulfuric acid (industrial sulfuric acid, 98%) is added in the continuous reactor simultaneously and reacts to generate barium sulfate slurry and hydrogen sulfide, and the adding rate of barium sulfide solution is 3000L / h, and the add-on of sulfuric acid is 12.5g / L according to the concentration of residual sulfuric acid in the barium sulfate slurry after the completion of the reaction calculate;

[0031] (c) Pass hot air into the barium sulfate slurry to discharge hydrogen...

Embodiment 3

[0035] The remaining steps are the same as in Example 2, except that in step (d), after dehydration and washing, the filter cake is dissolved in water to make barium sulfate slurry, and coupling agent KH-560 is added to the barium sulfate slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com